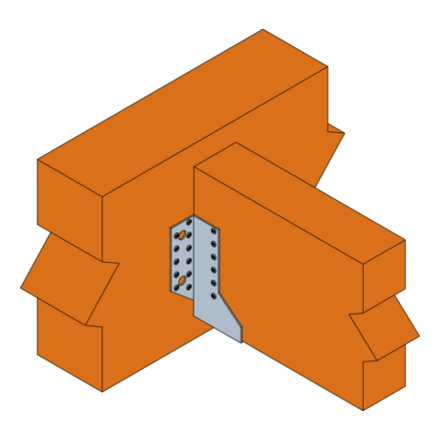

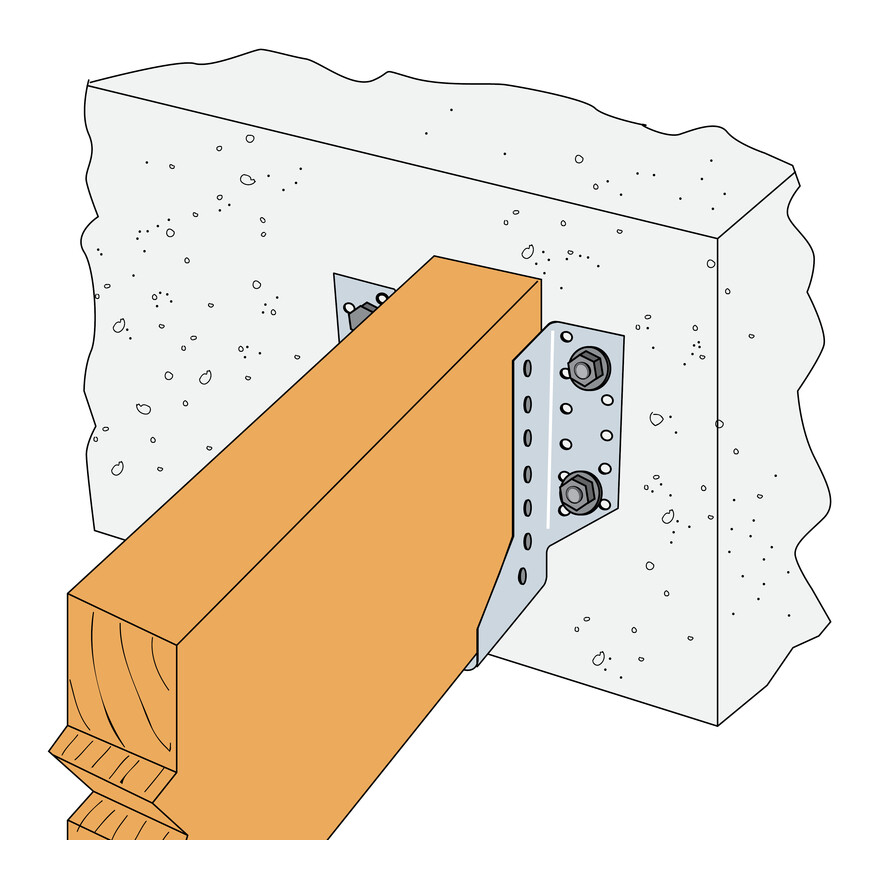

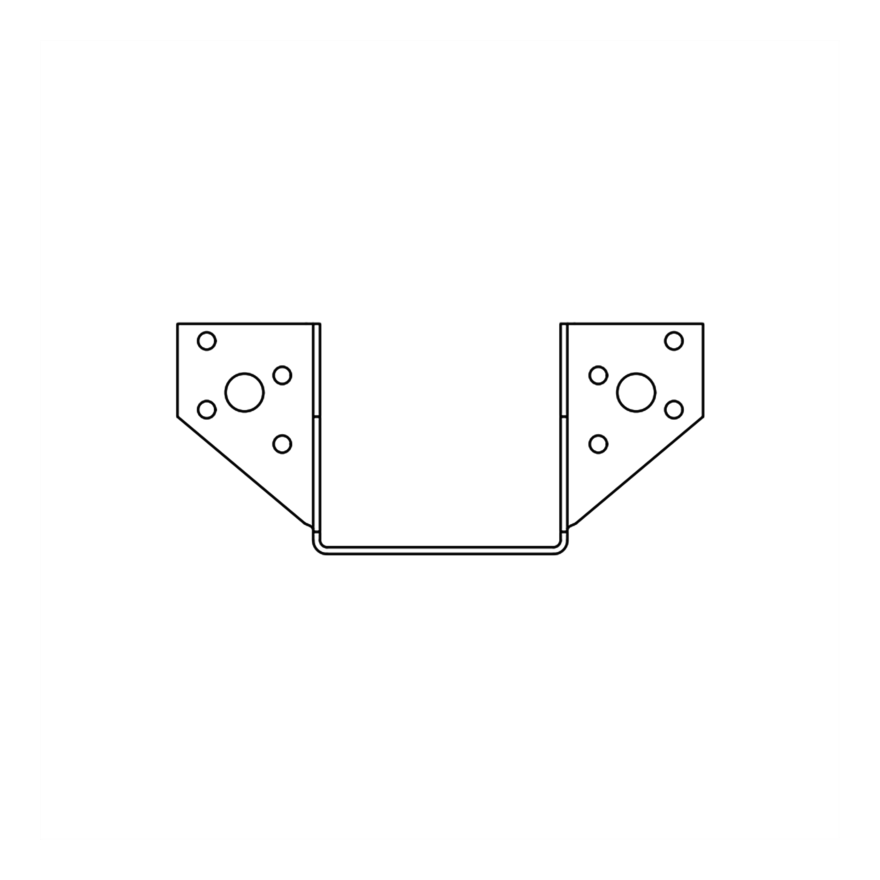

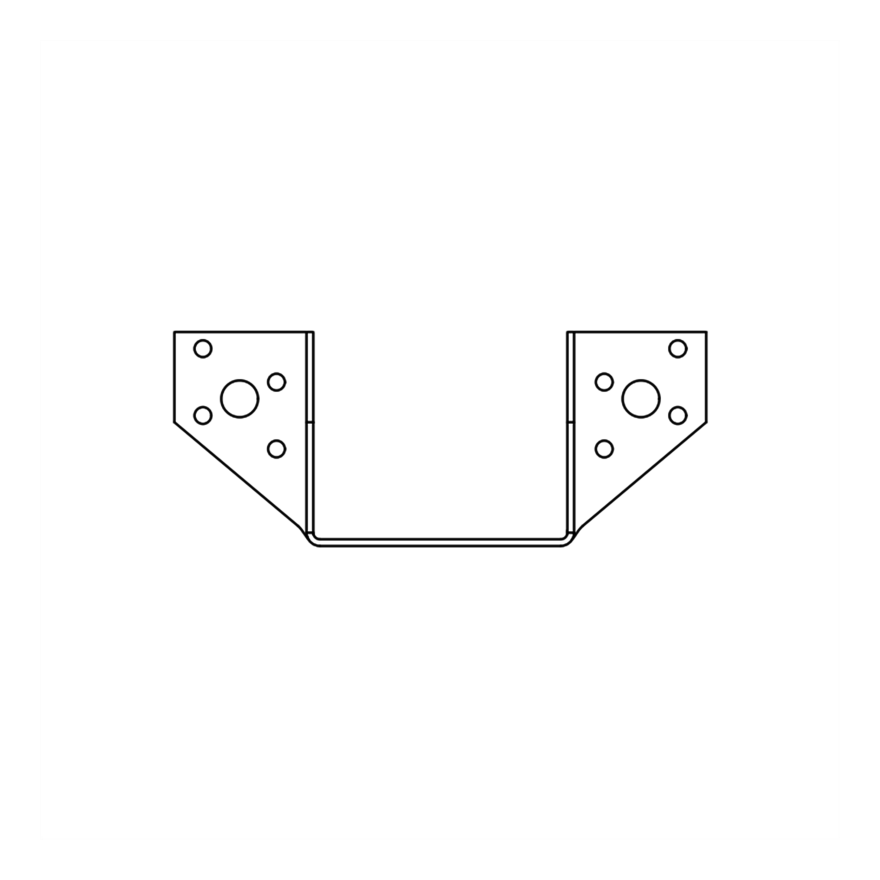

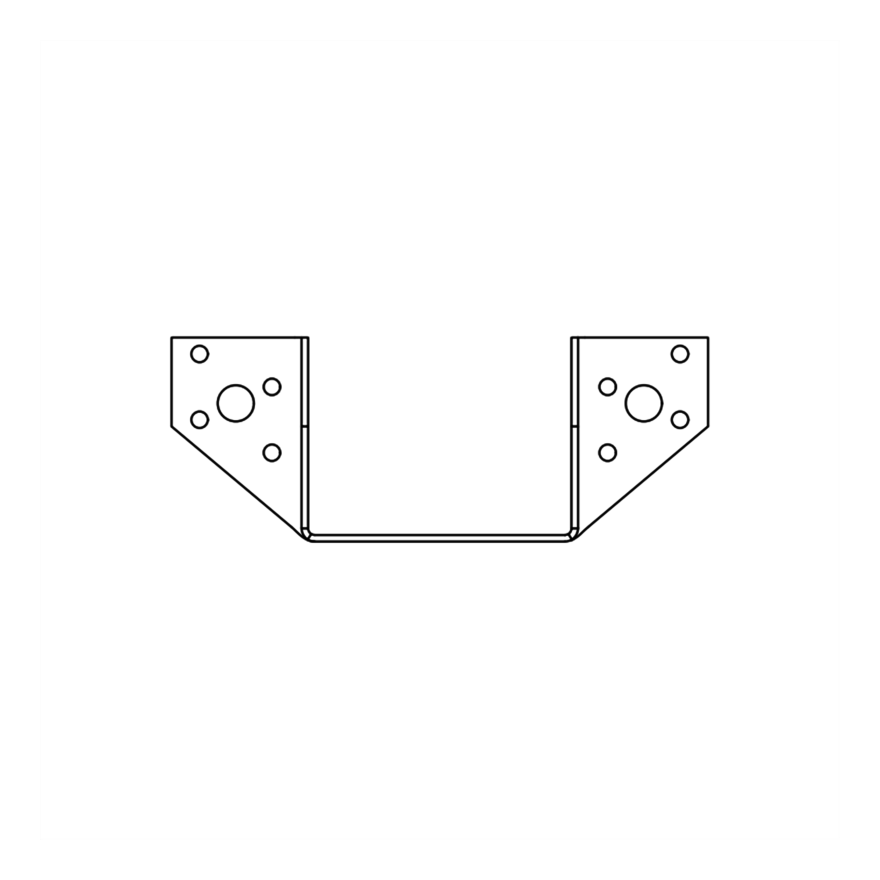

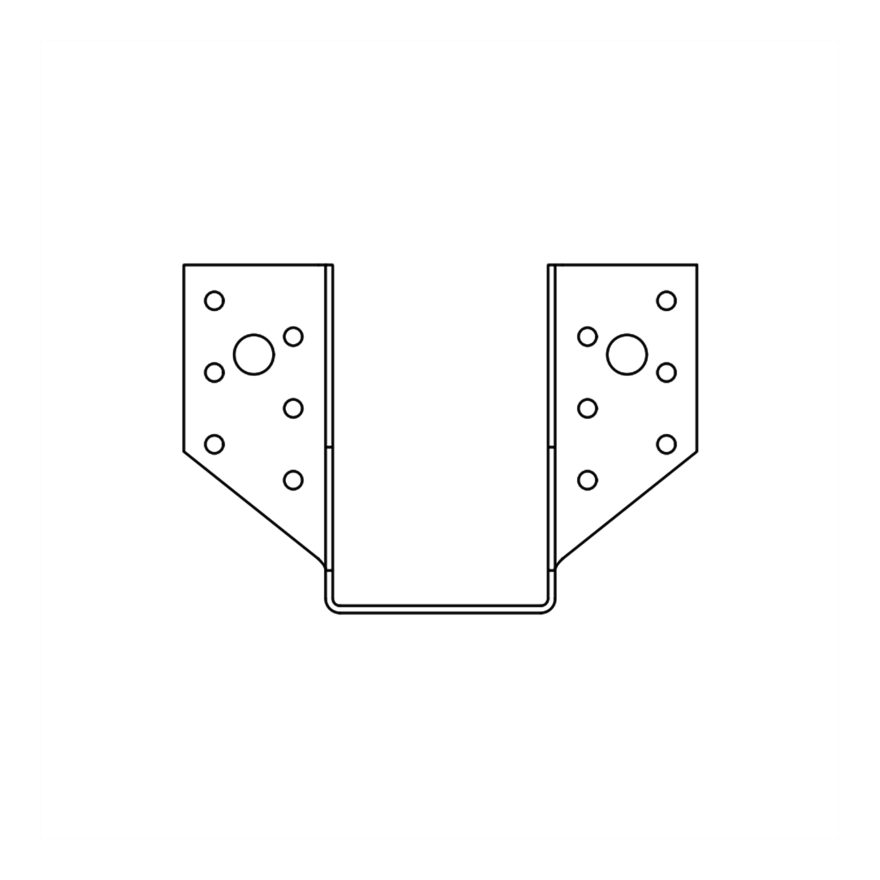

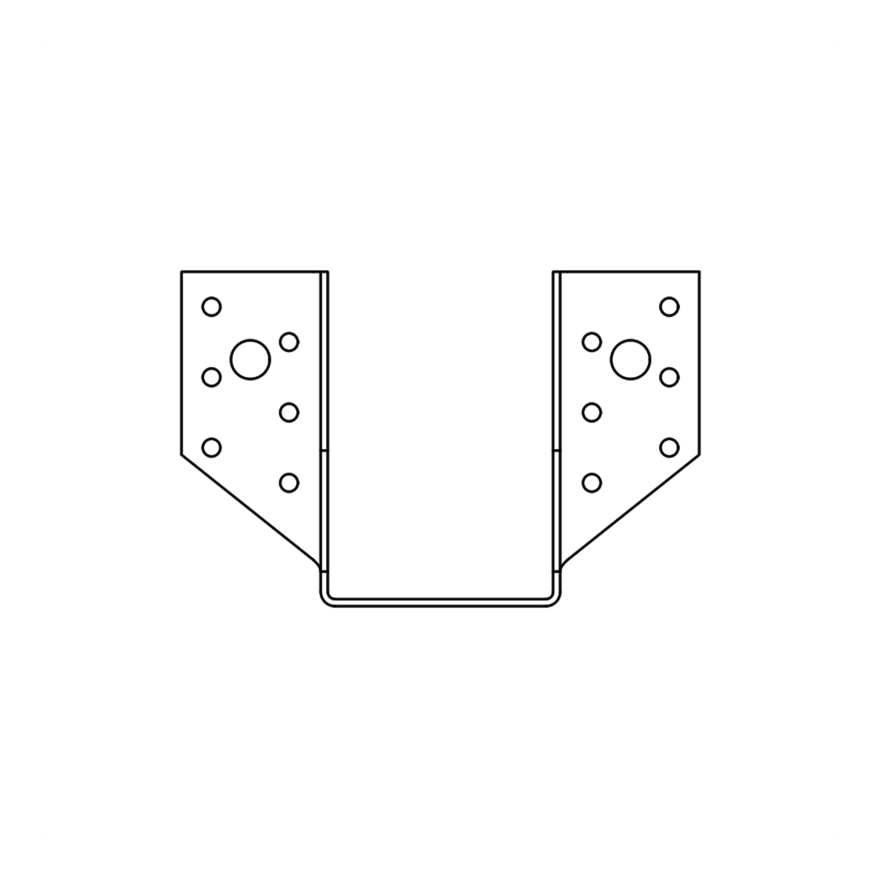

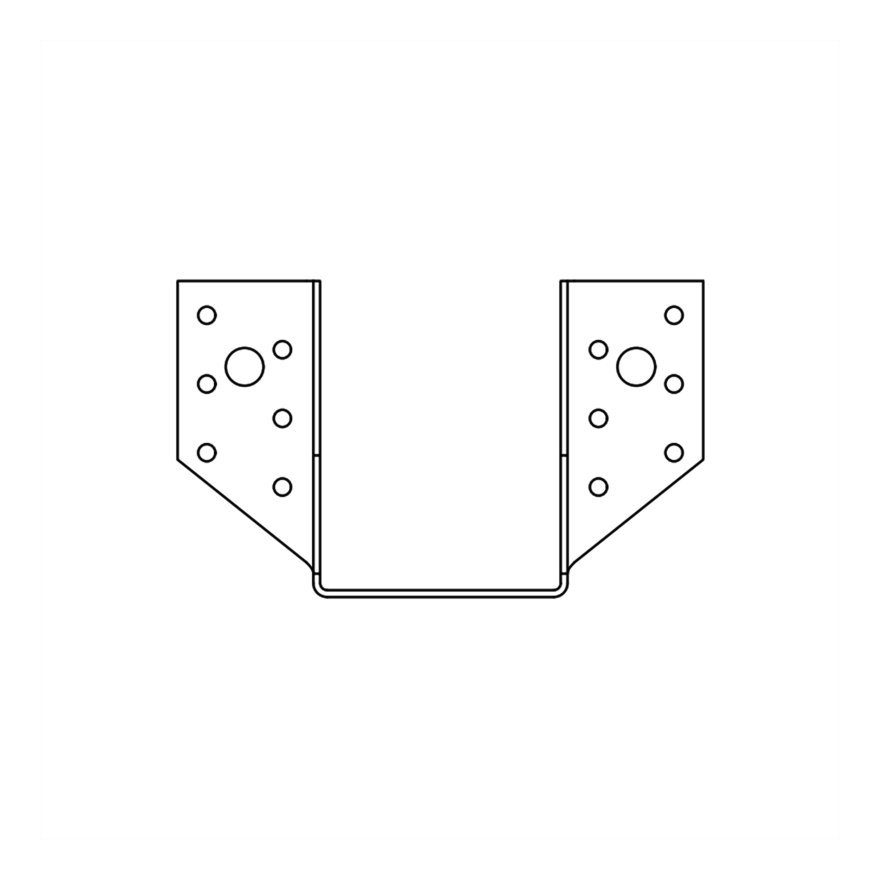

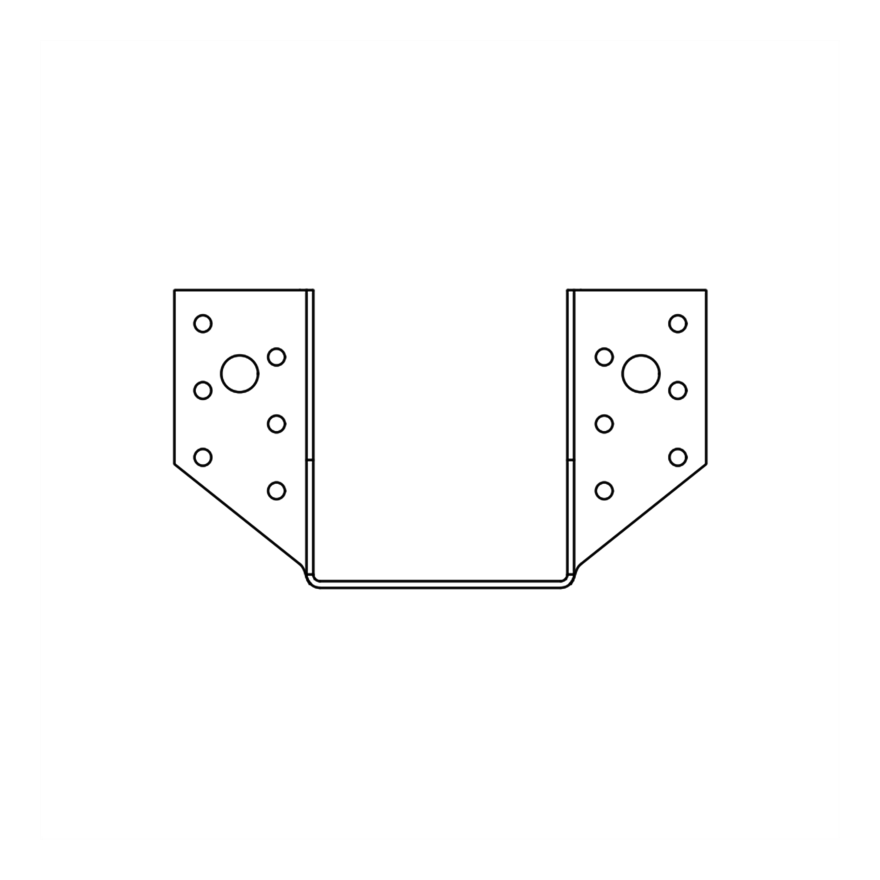

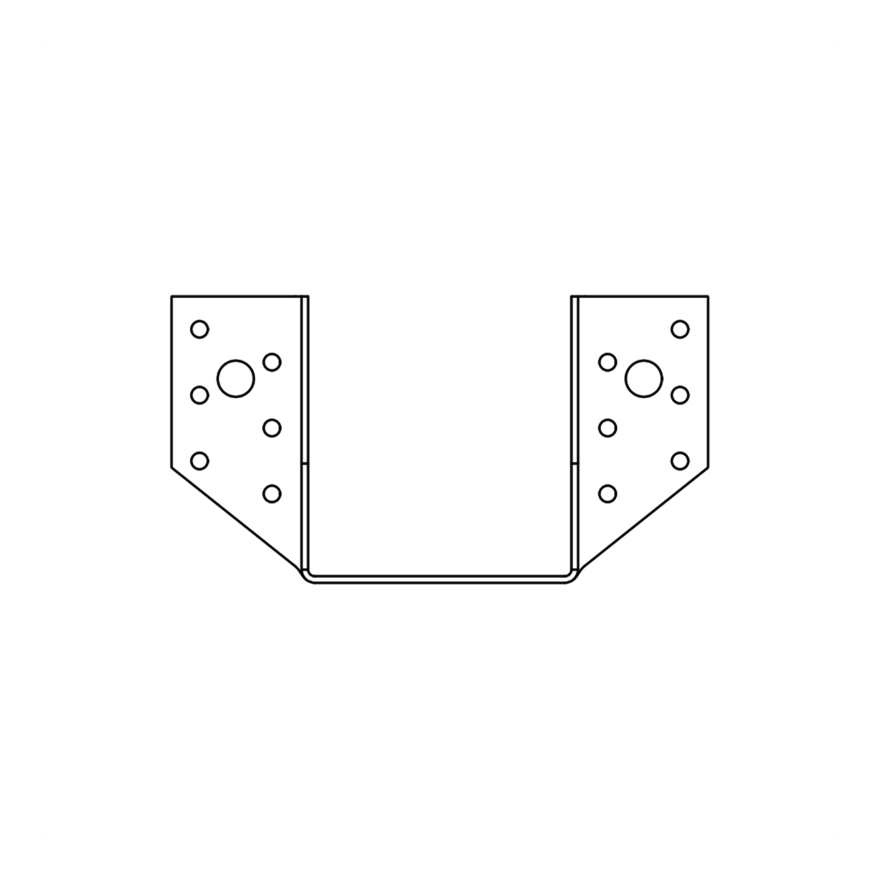

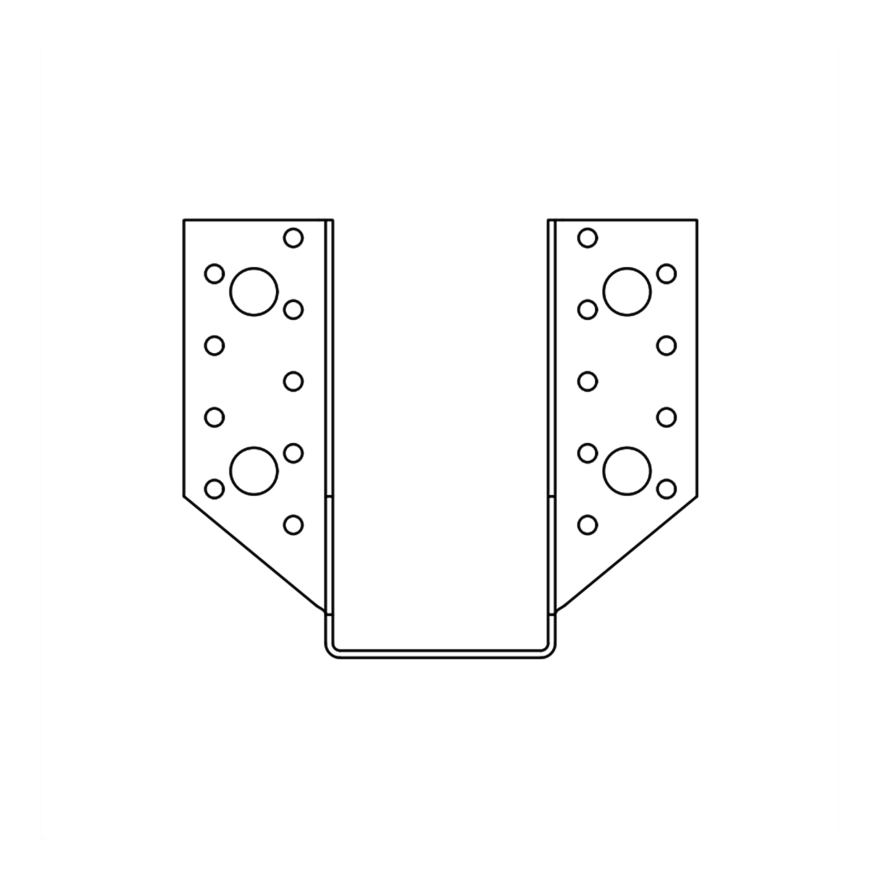

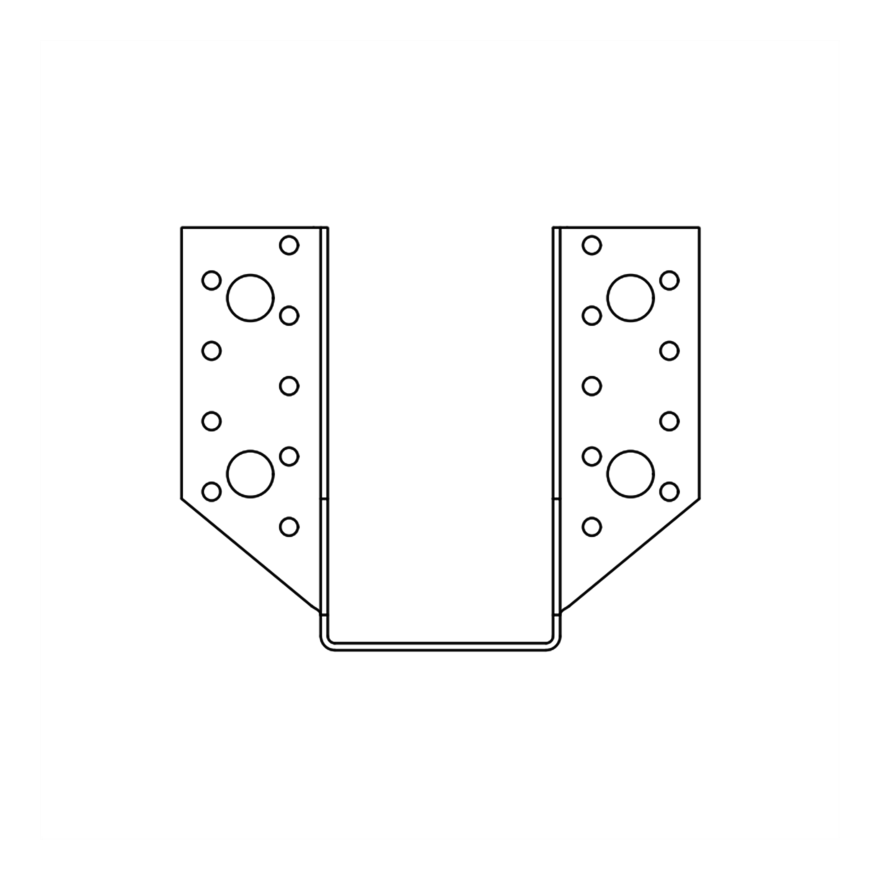

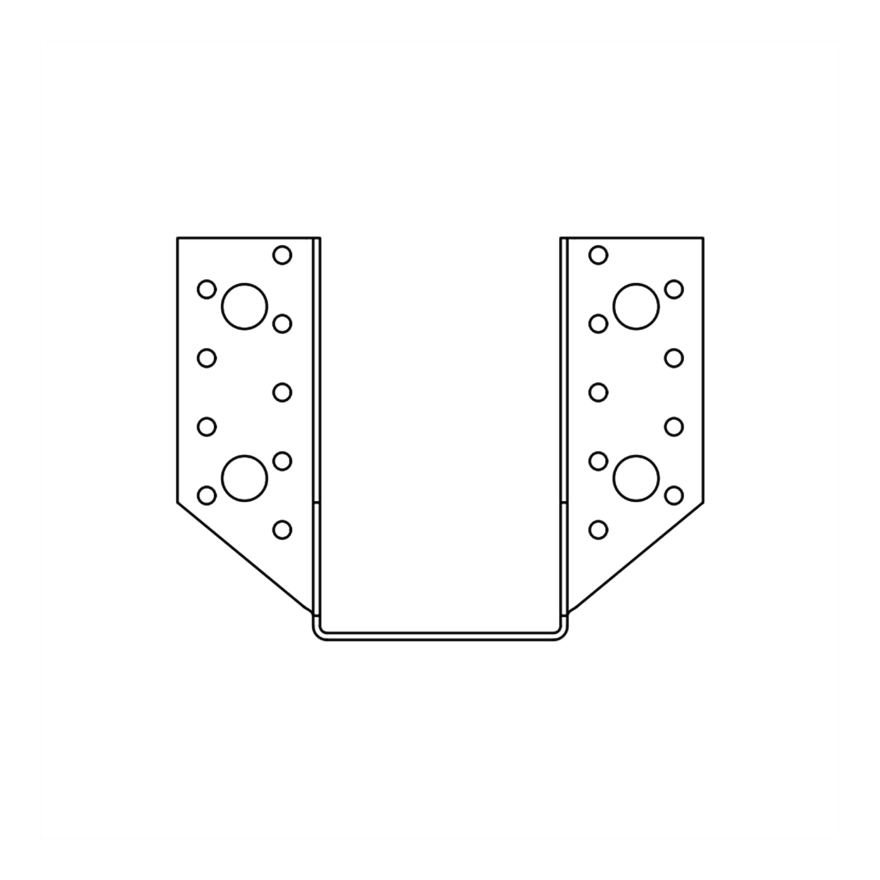

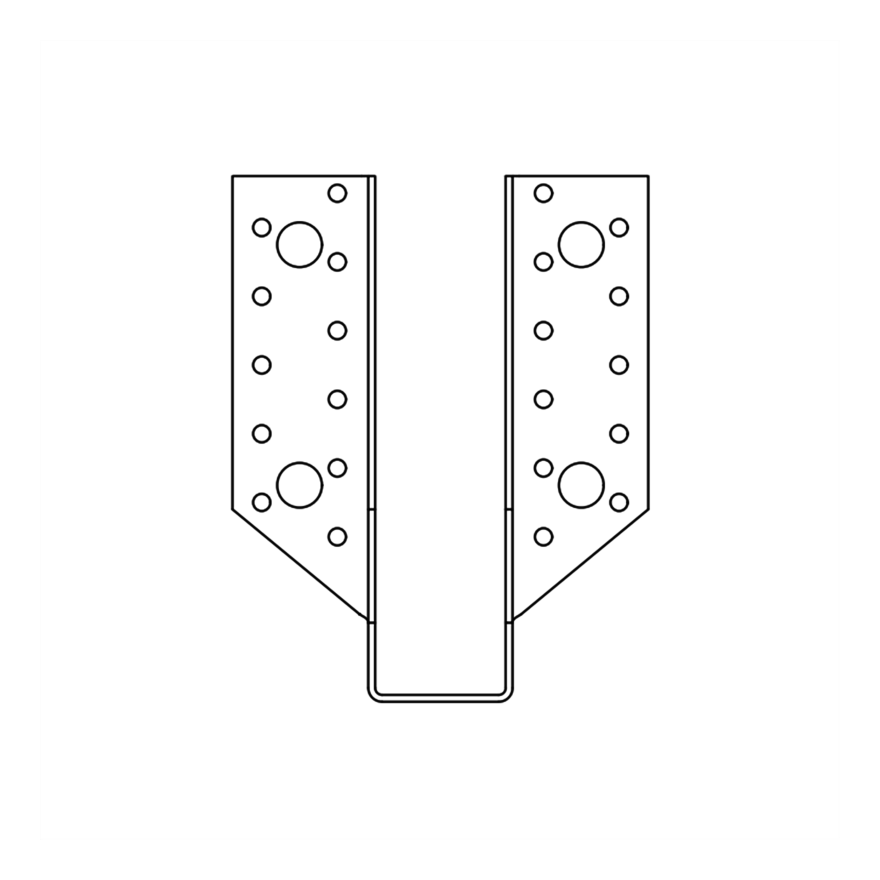

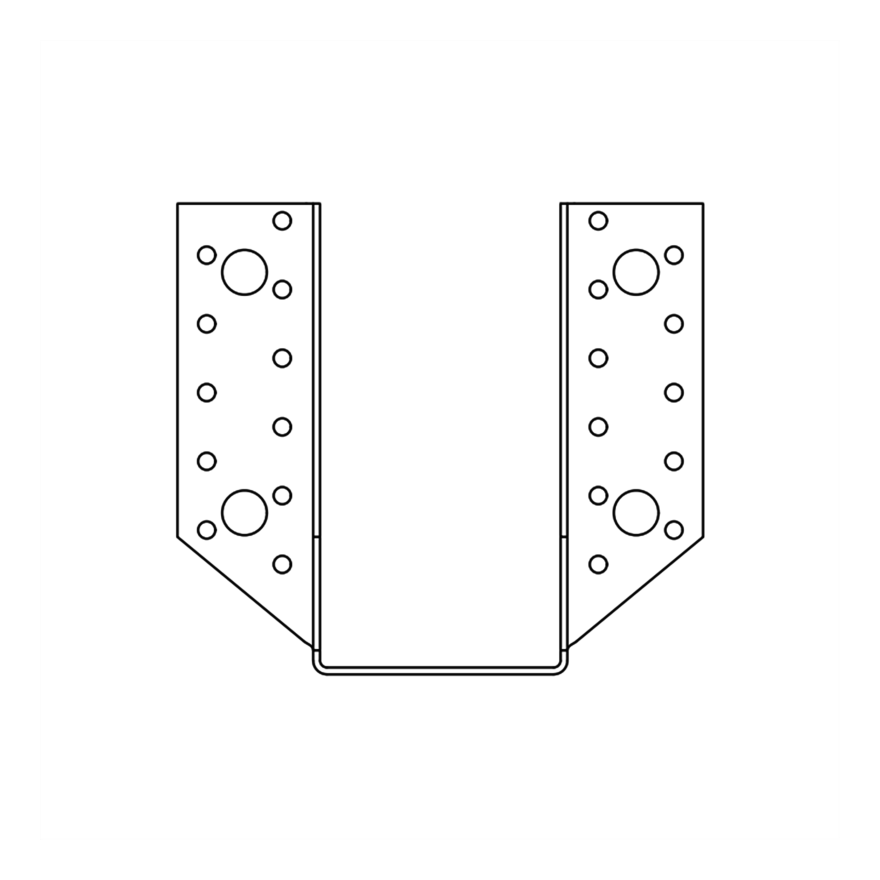

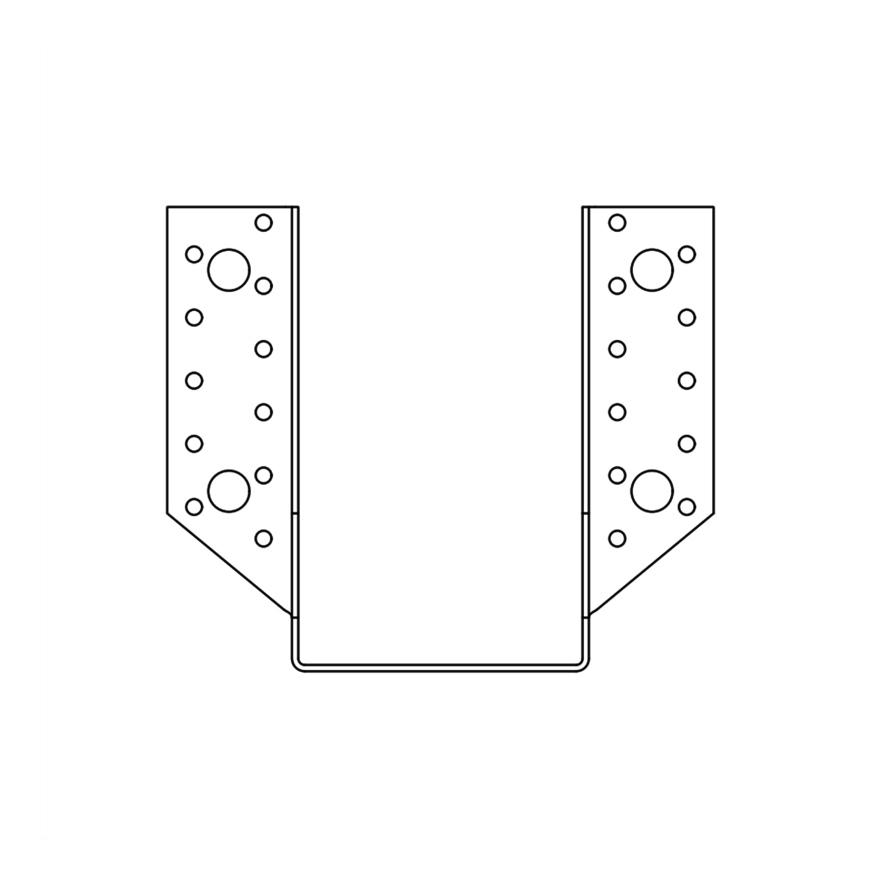

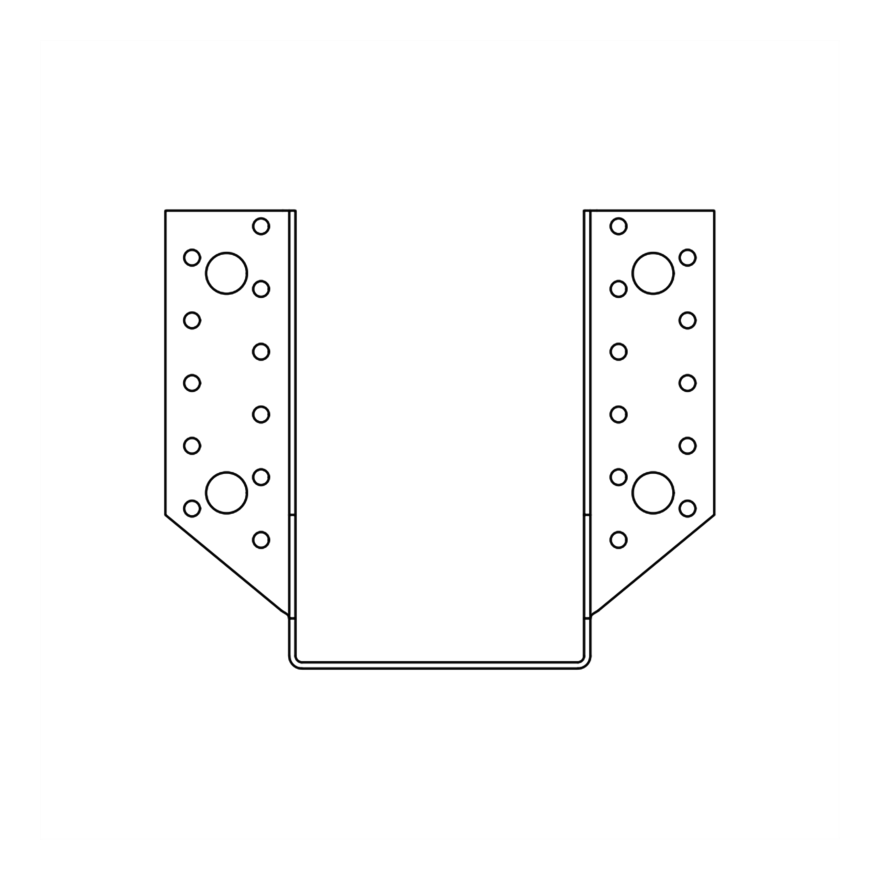

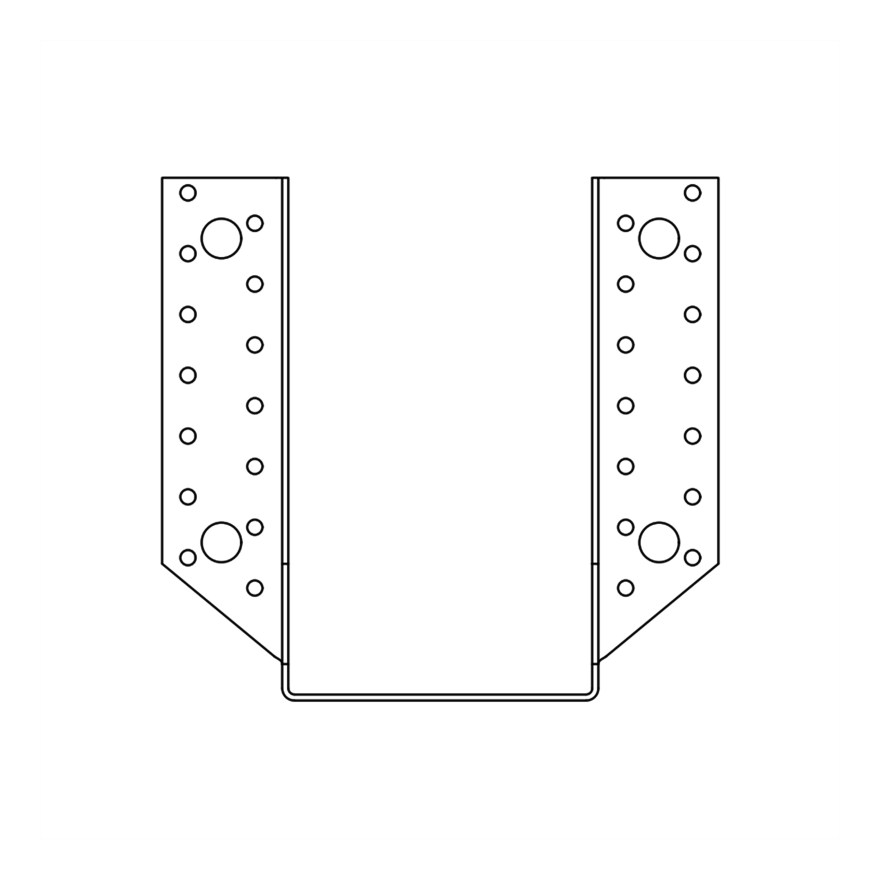

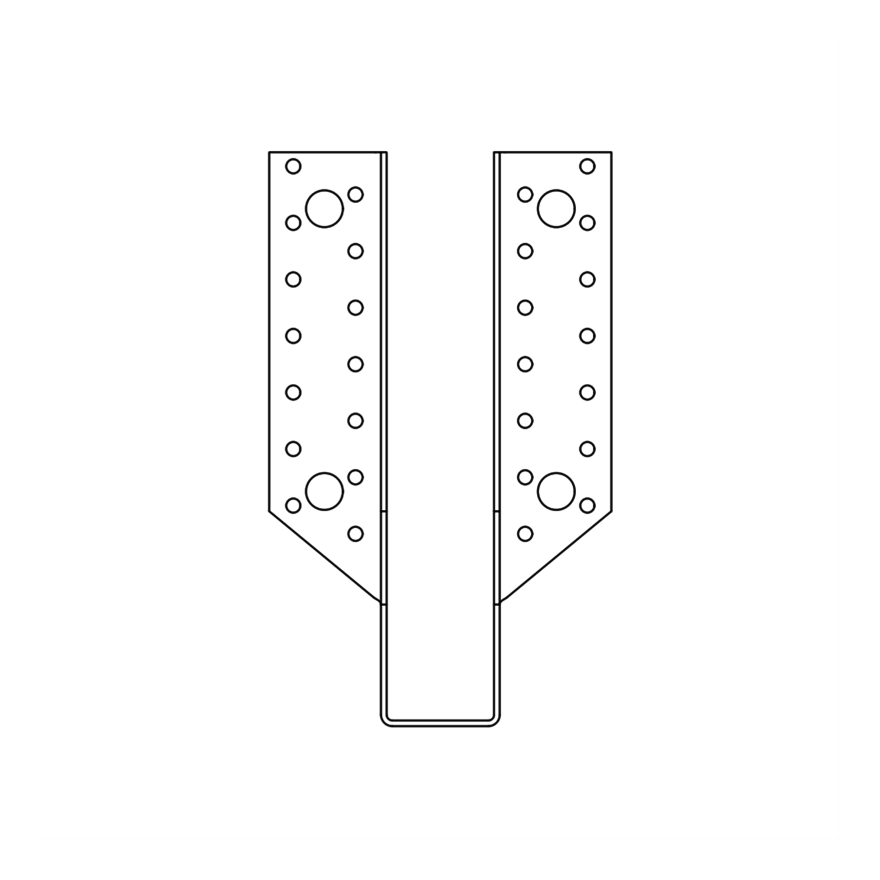

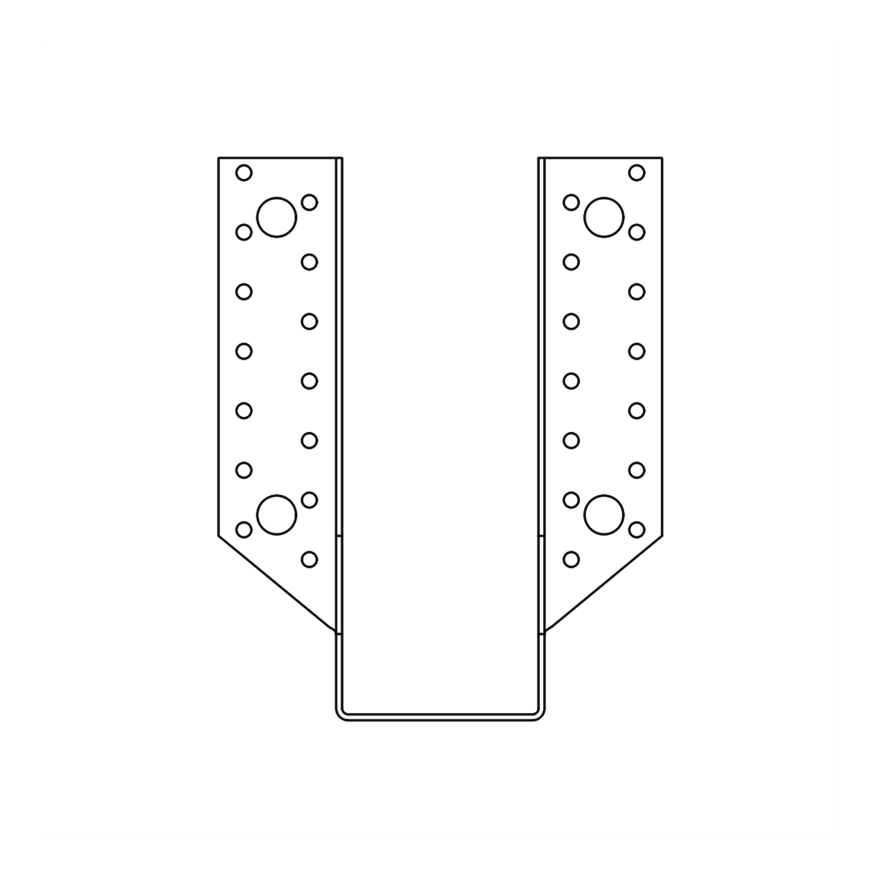

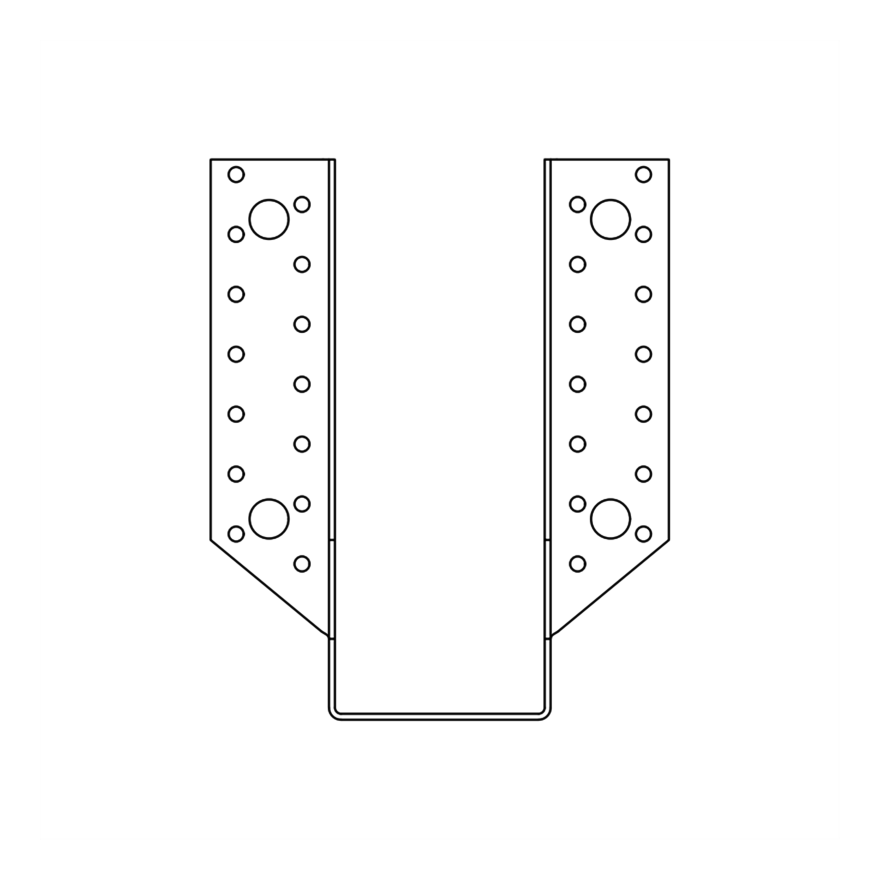

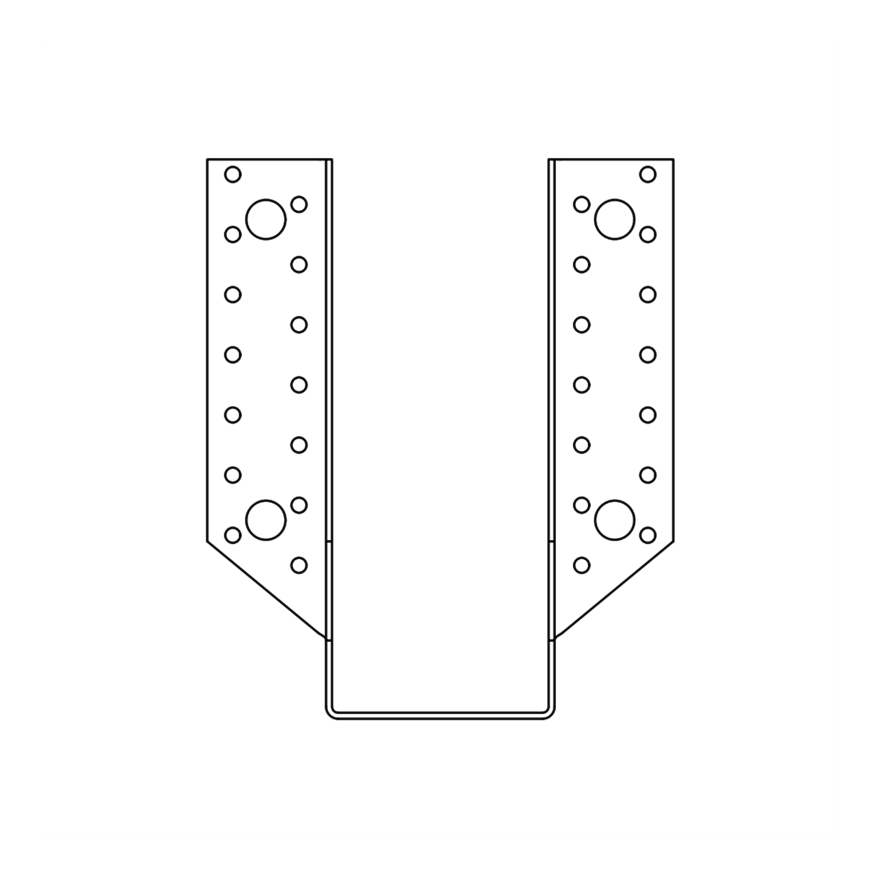

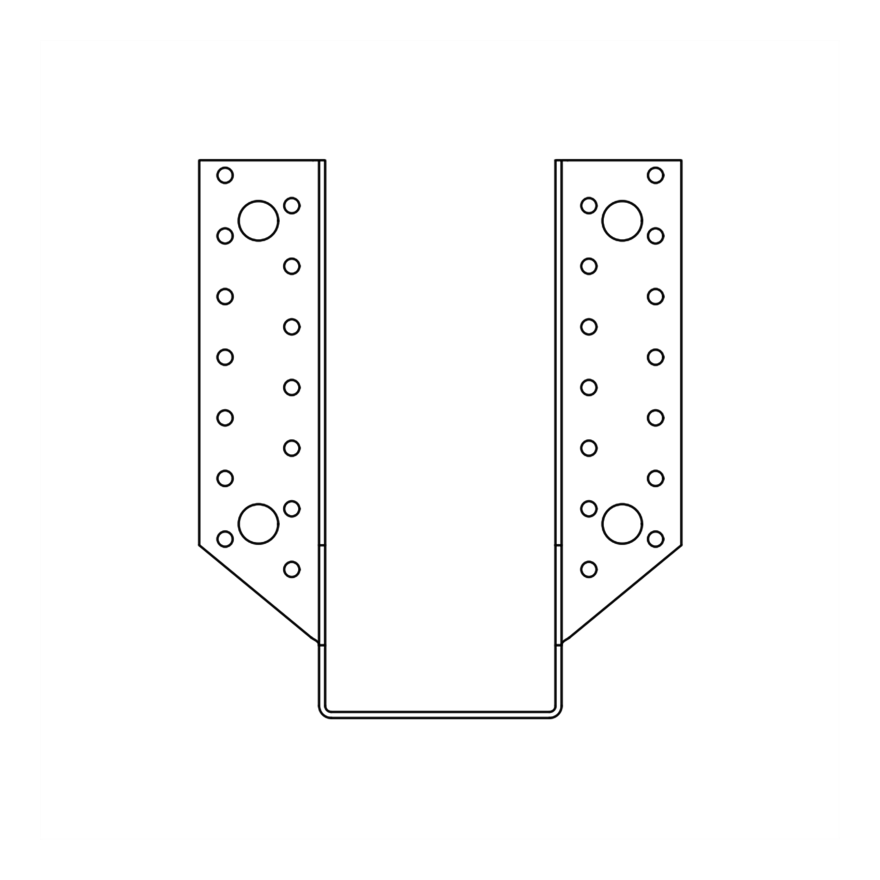

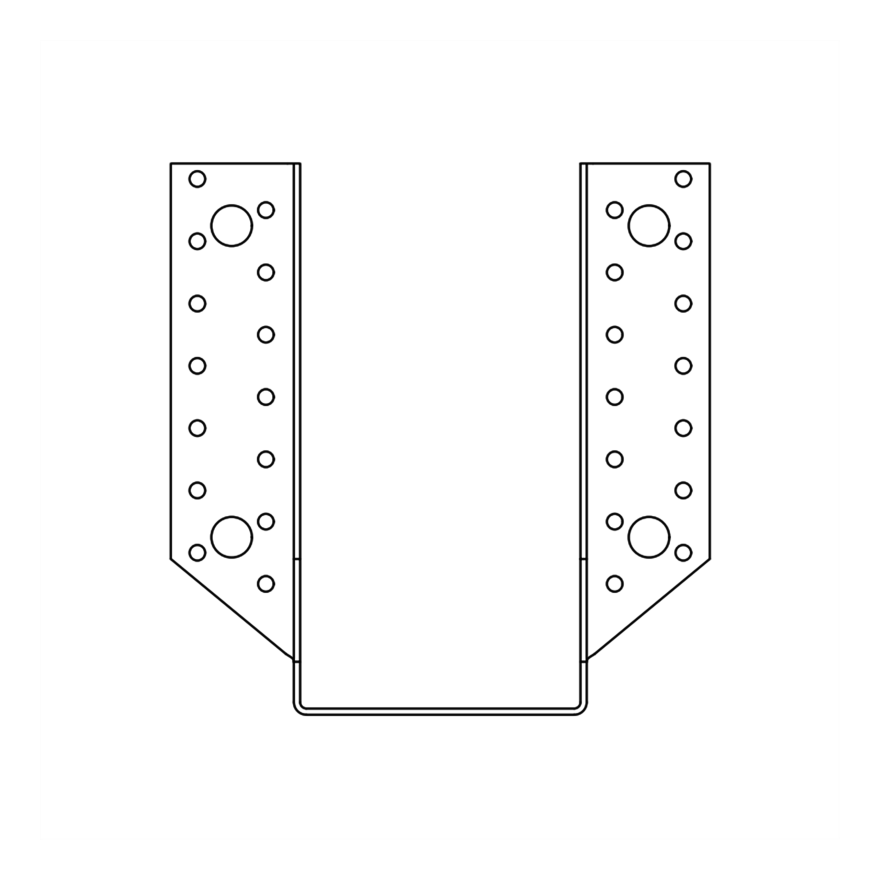

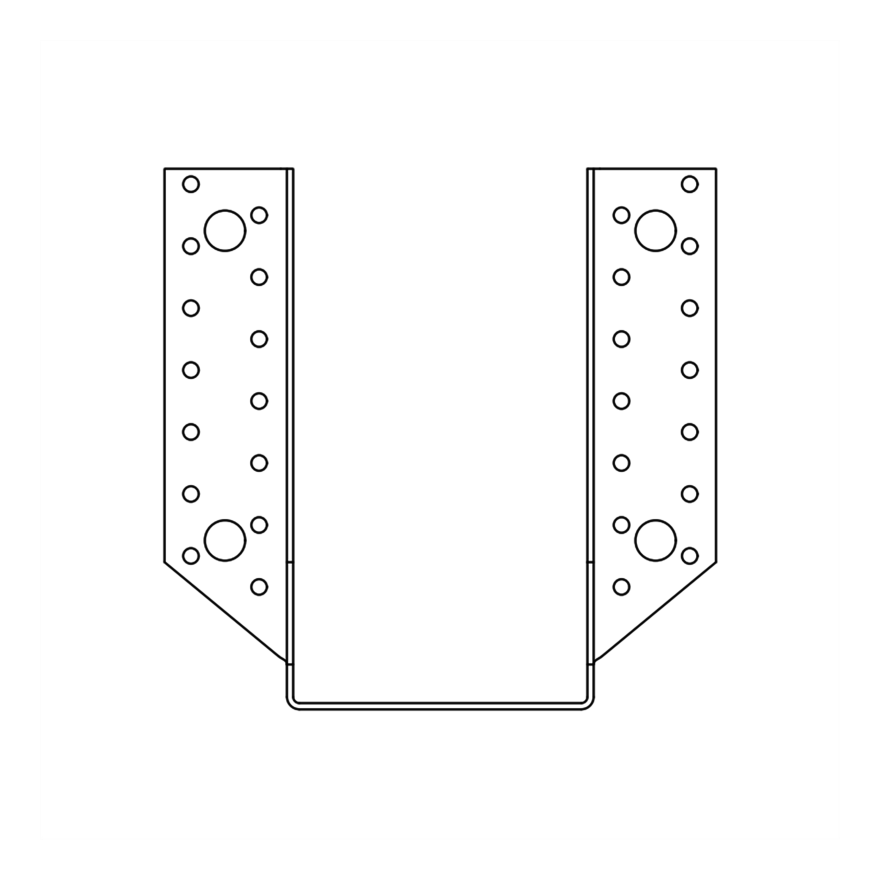

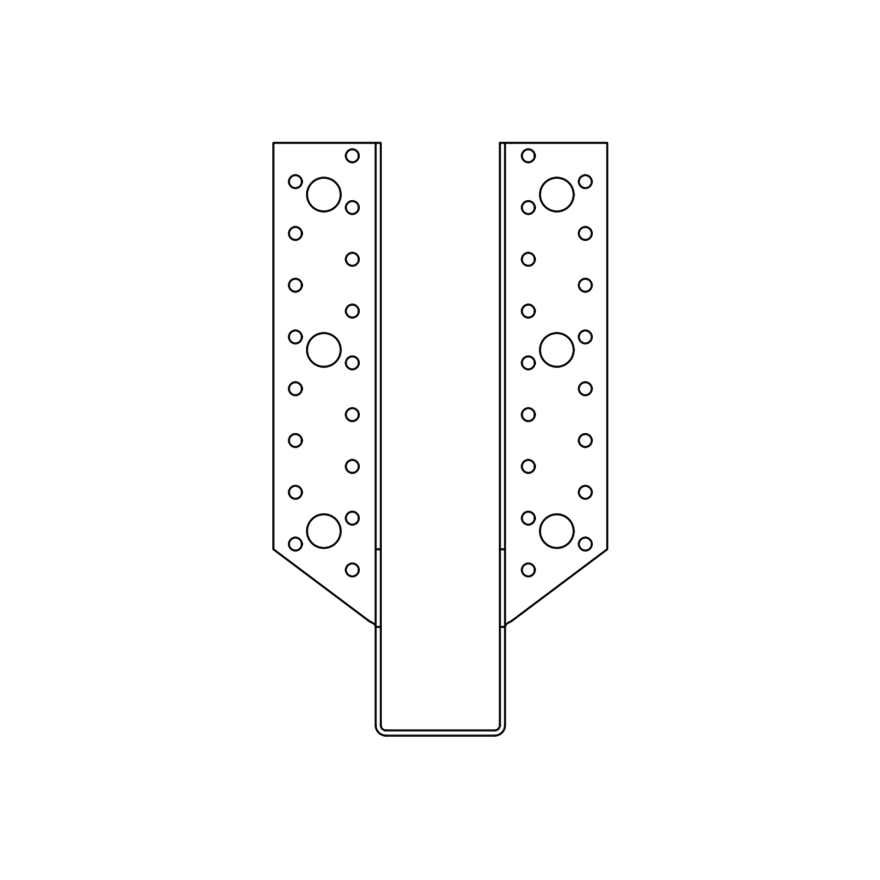

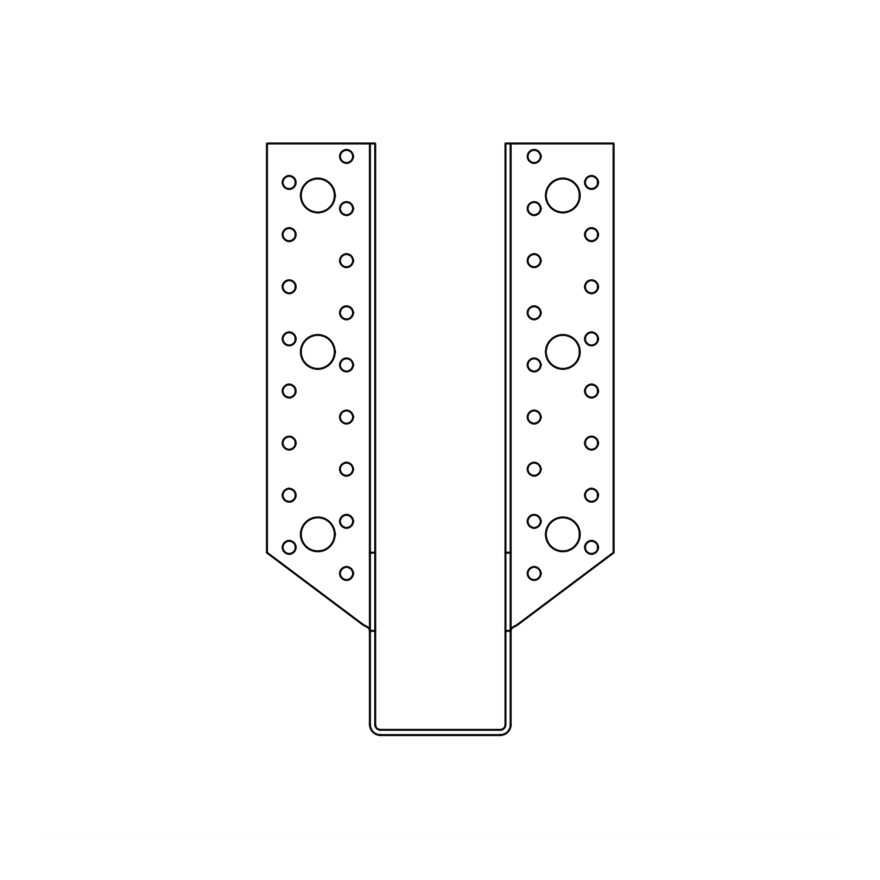

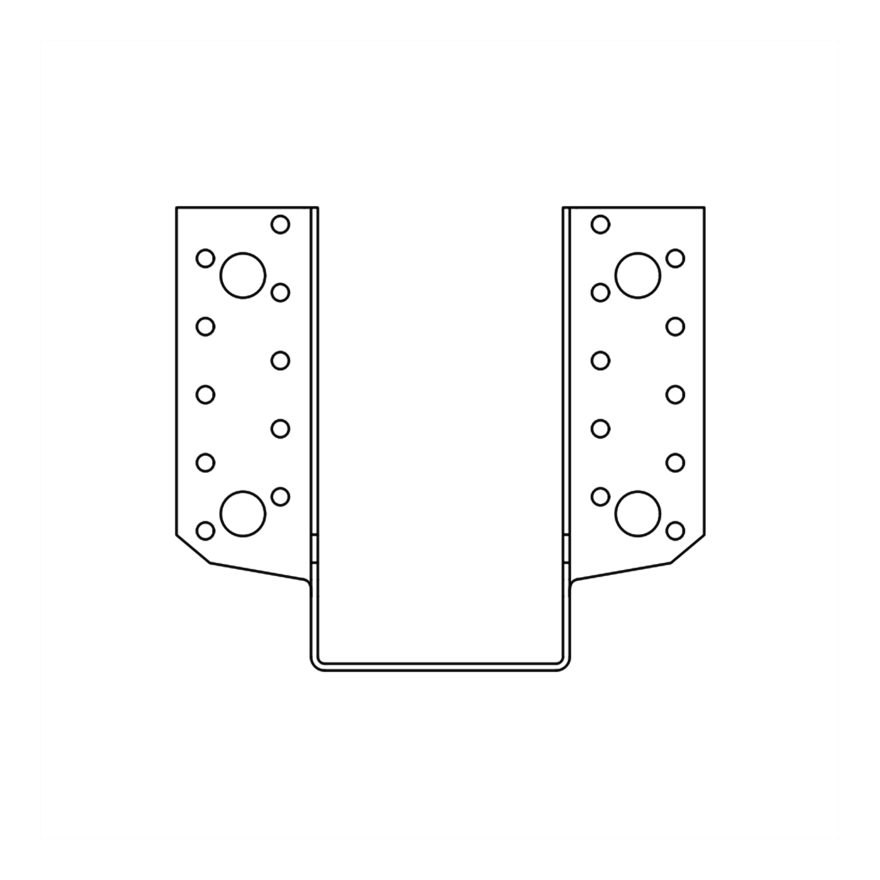

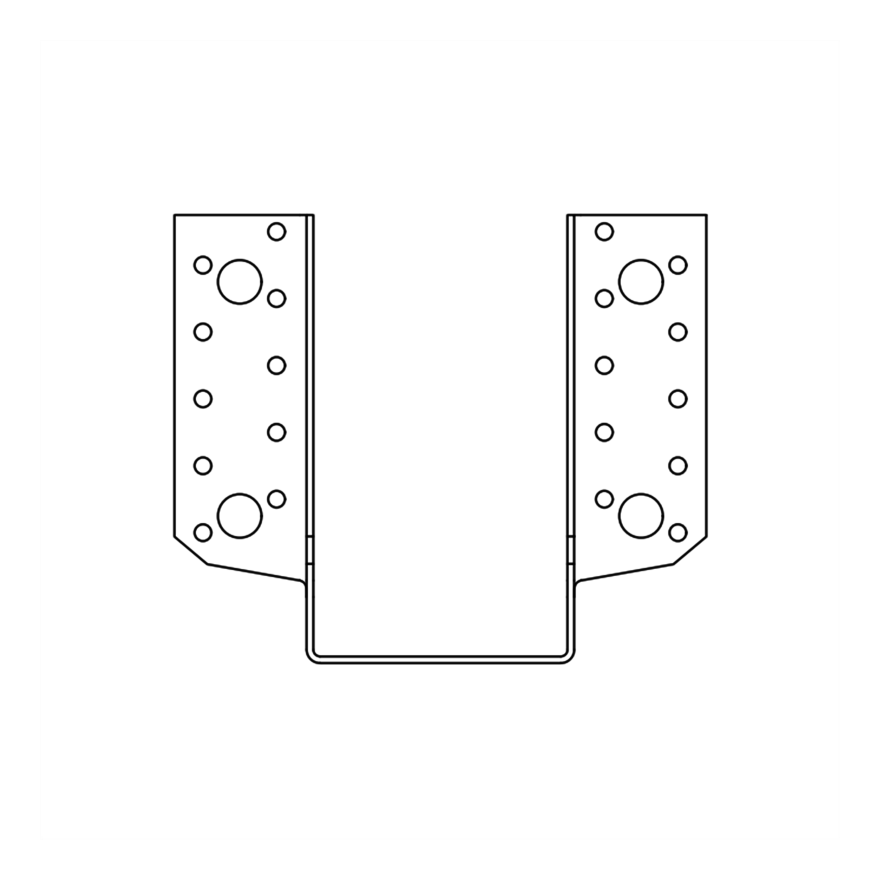

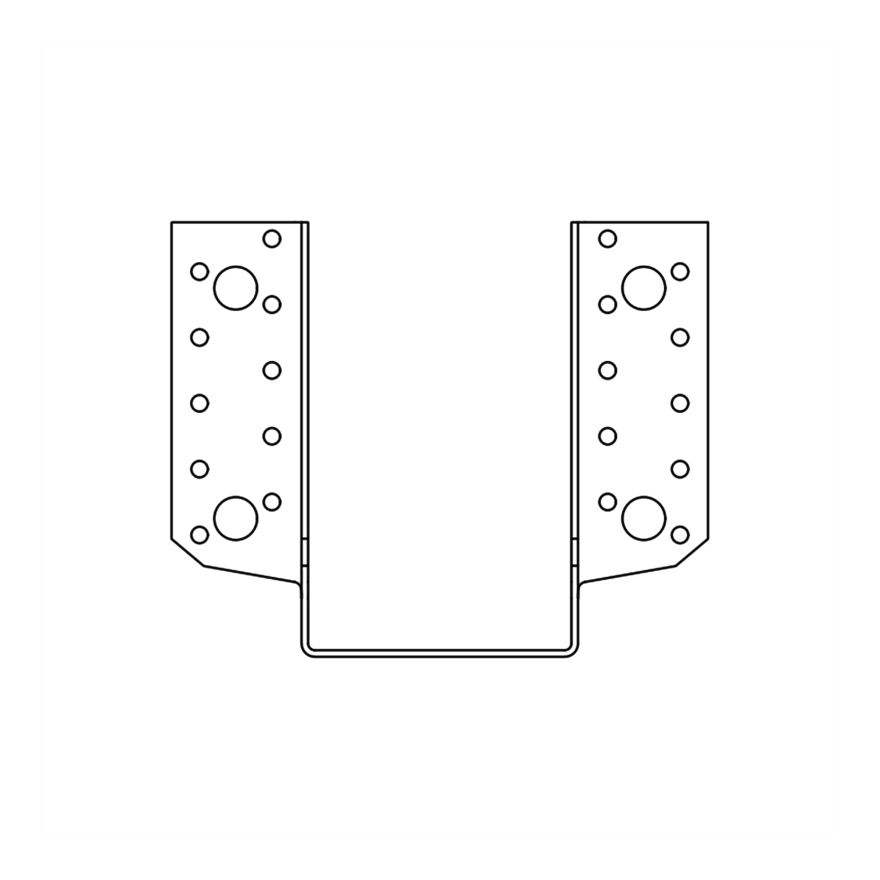

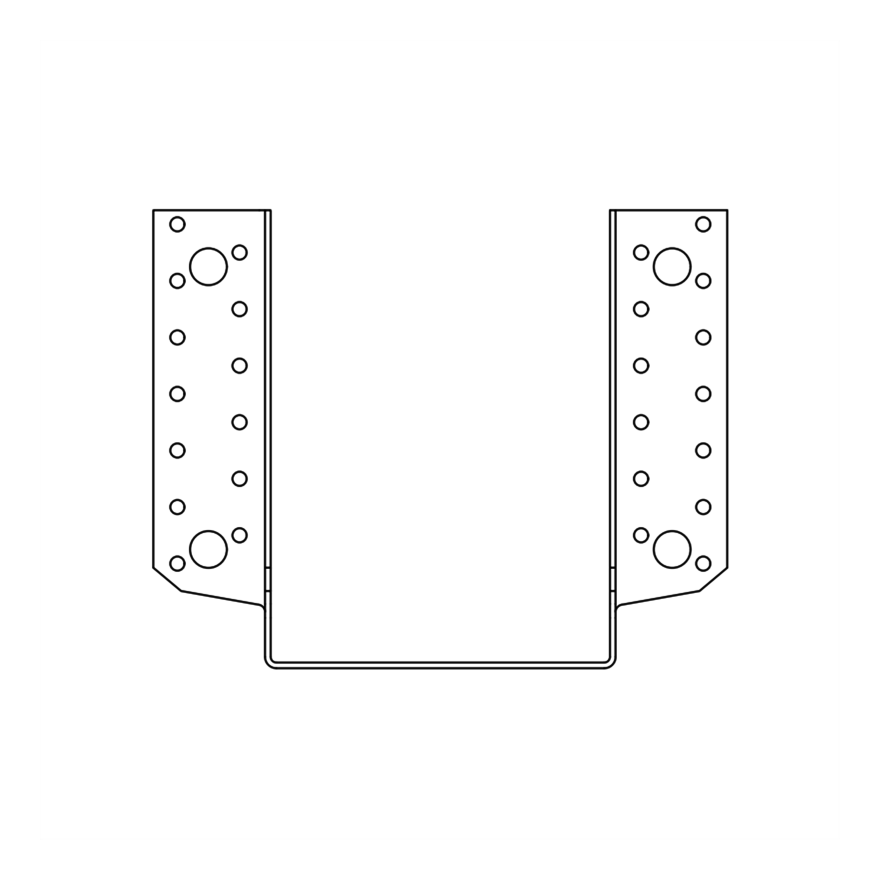

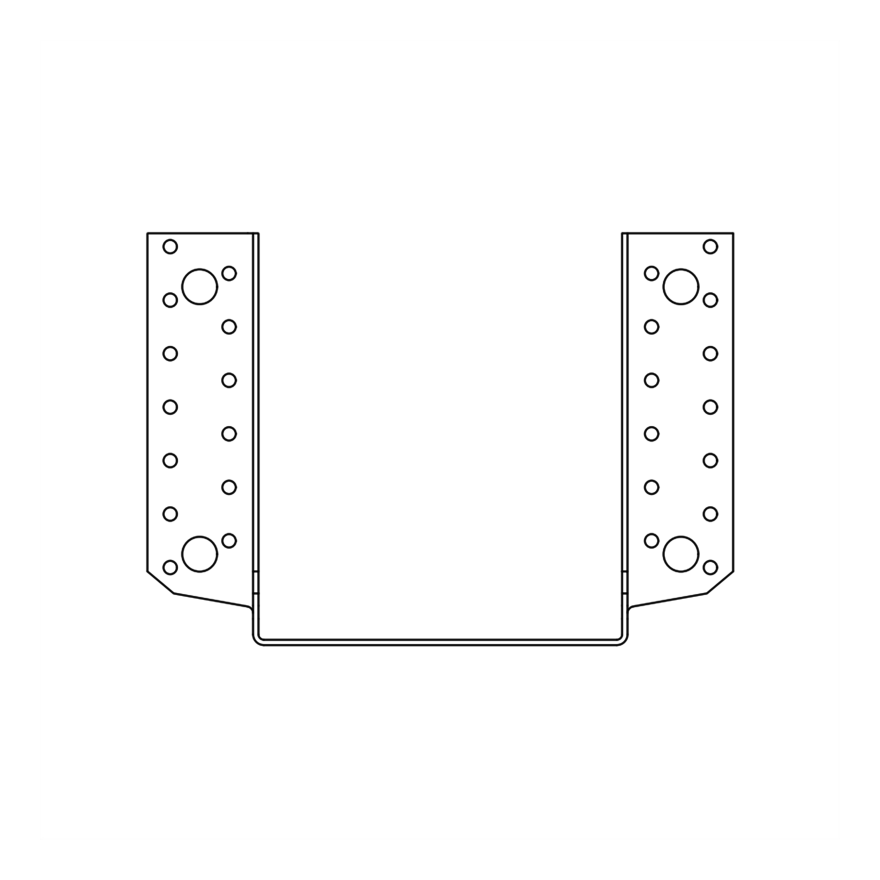

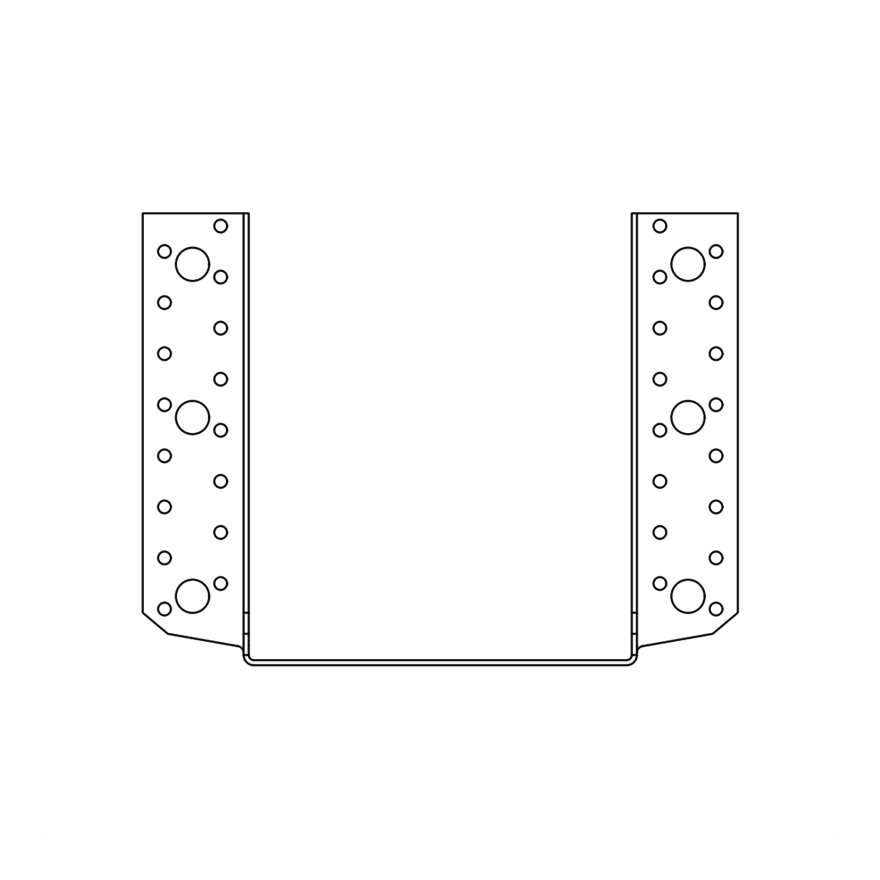

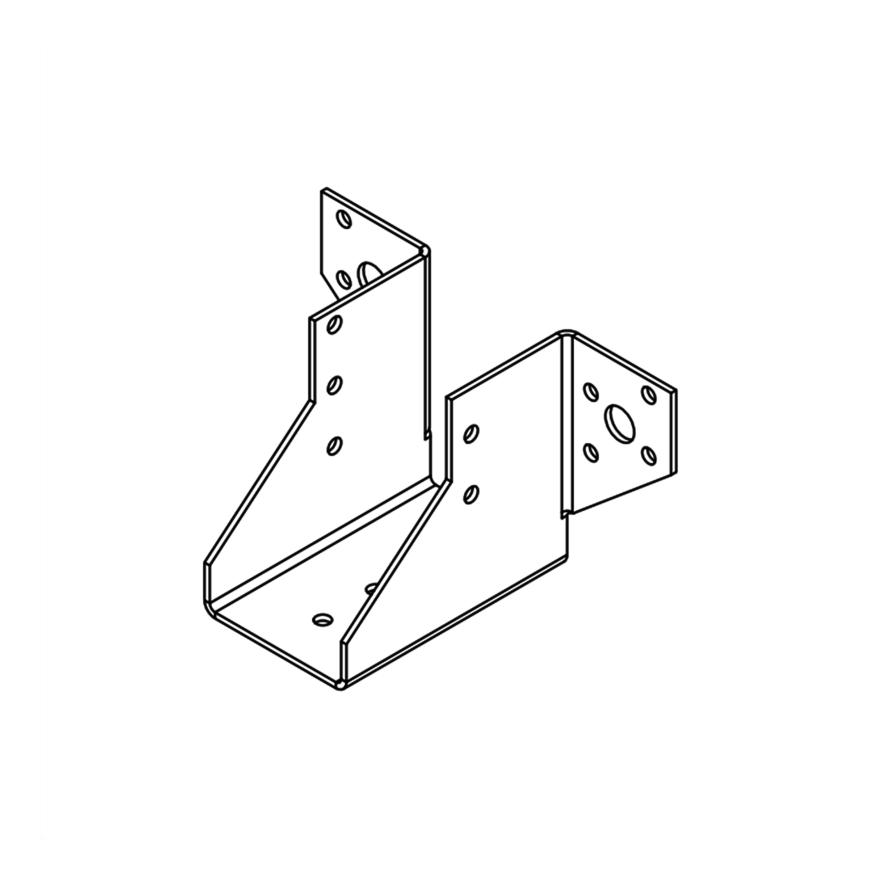

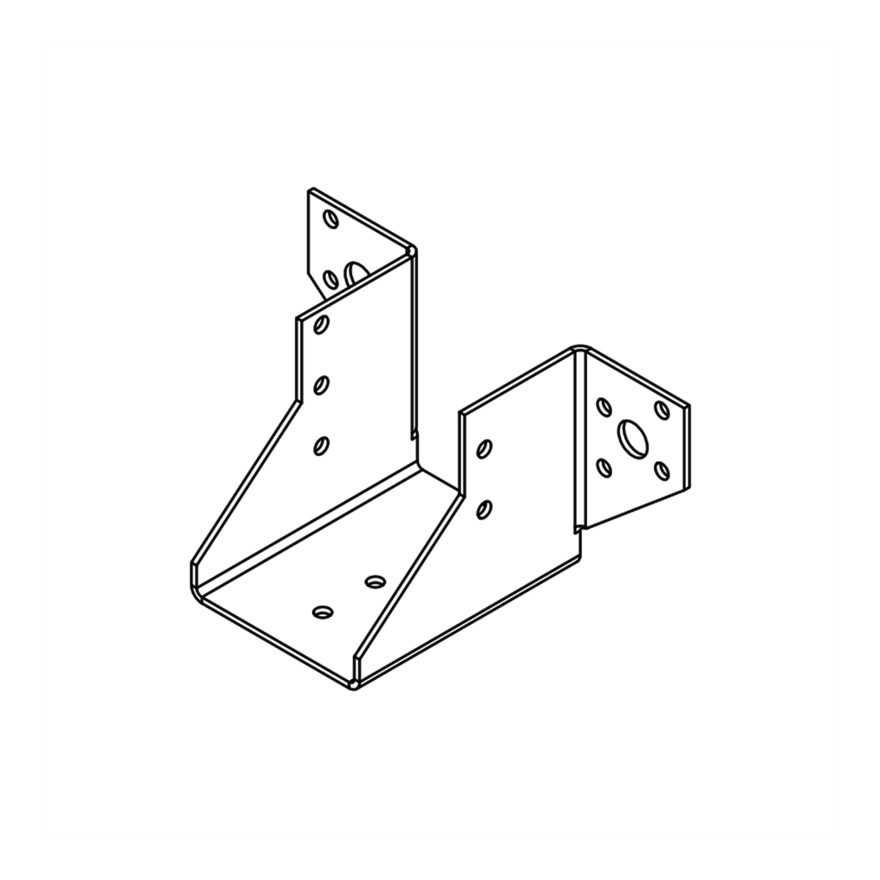

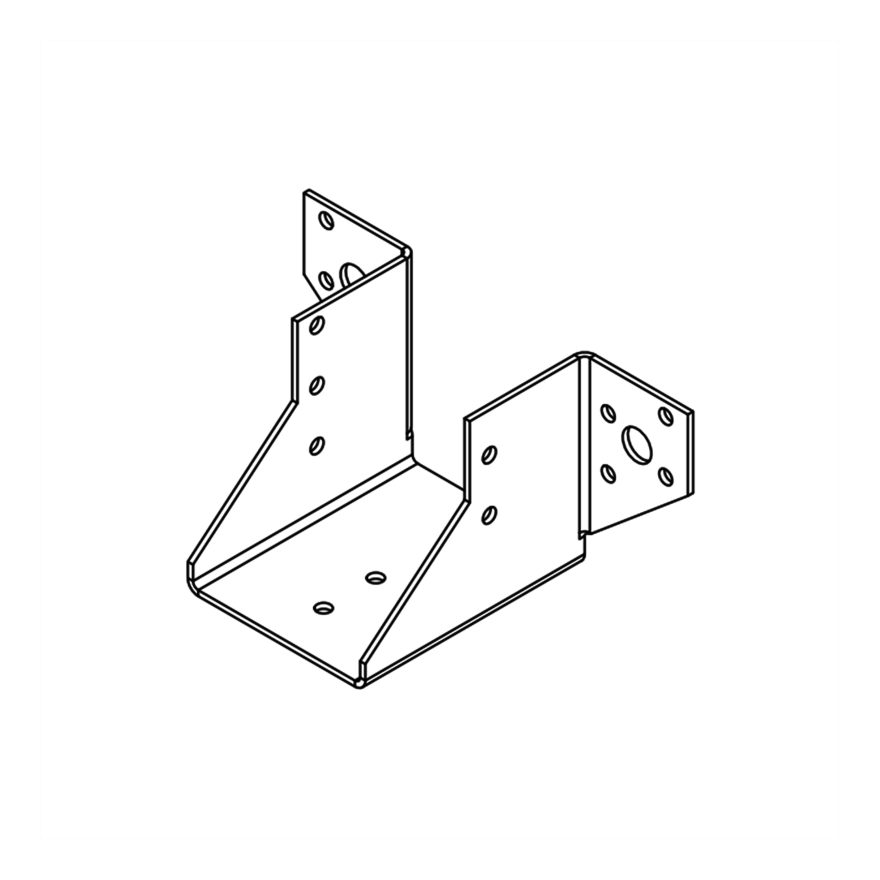

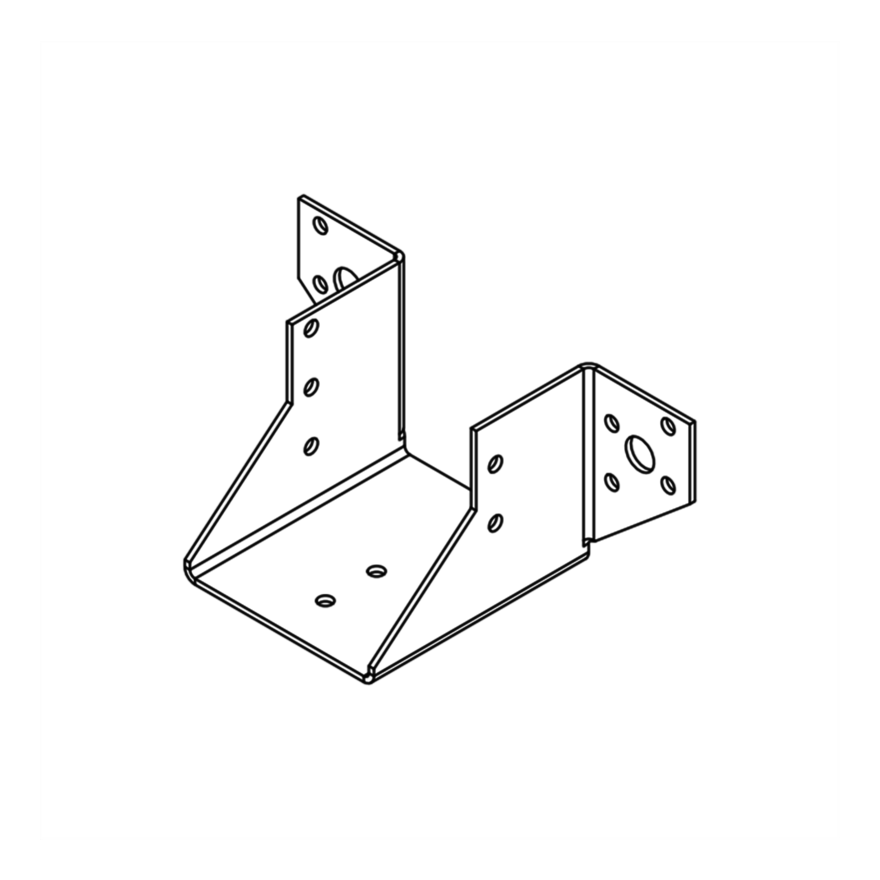

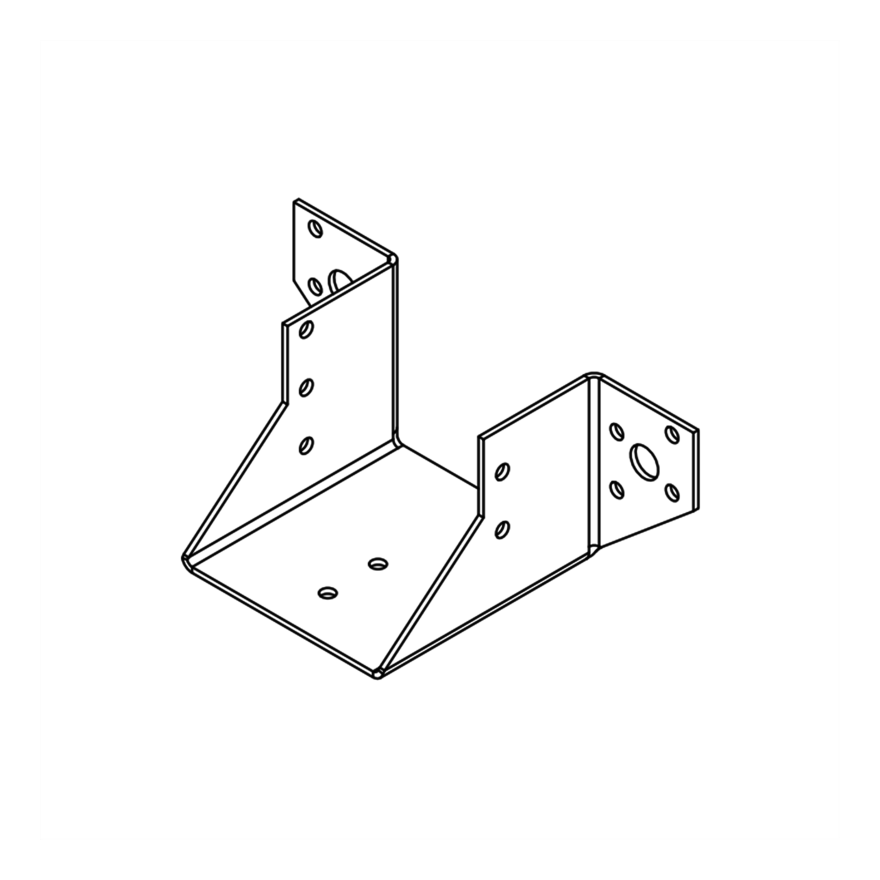

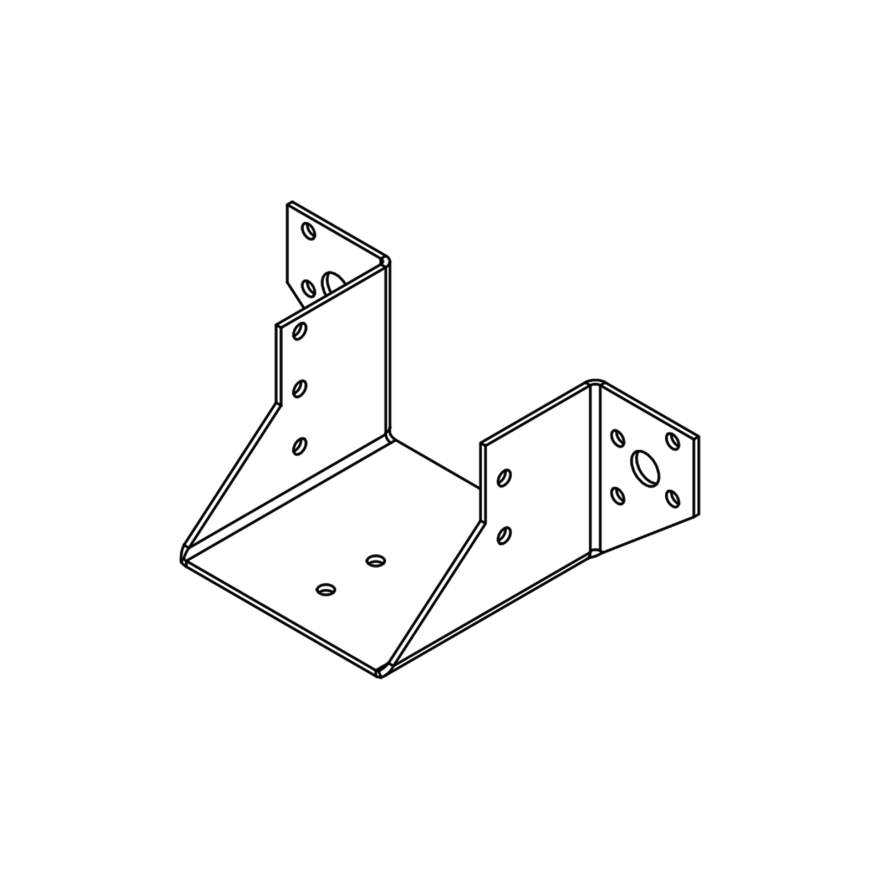

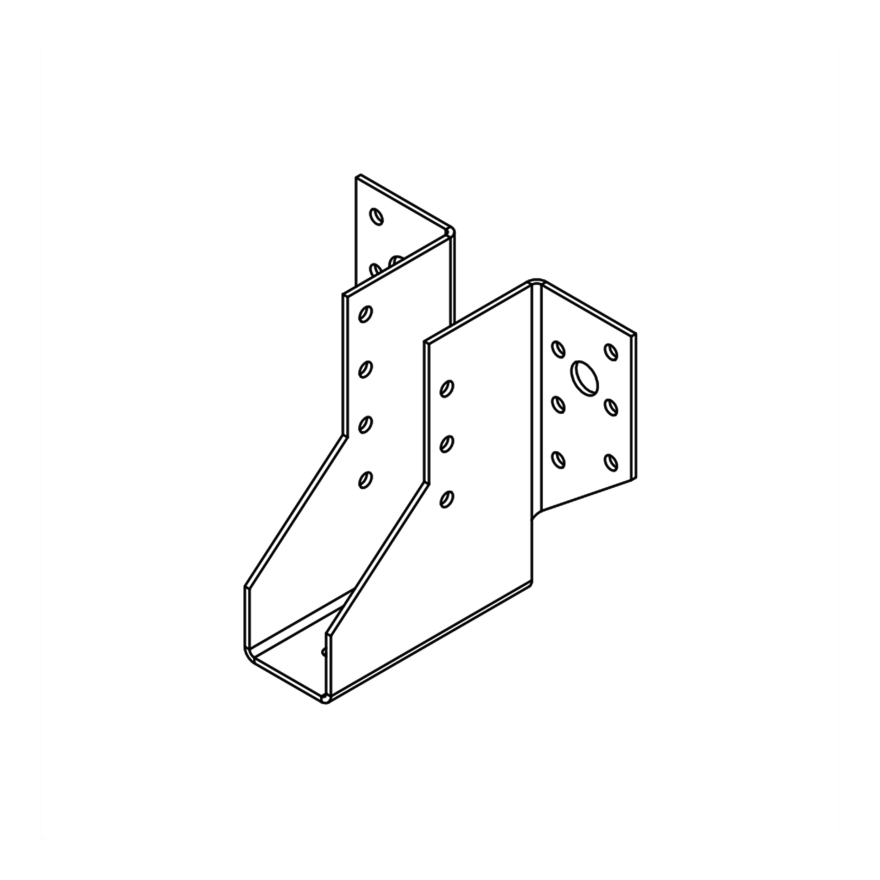

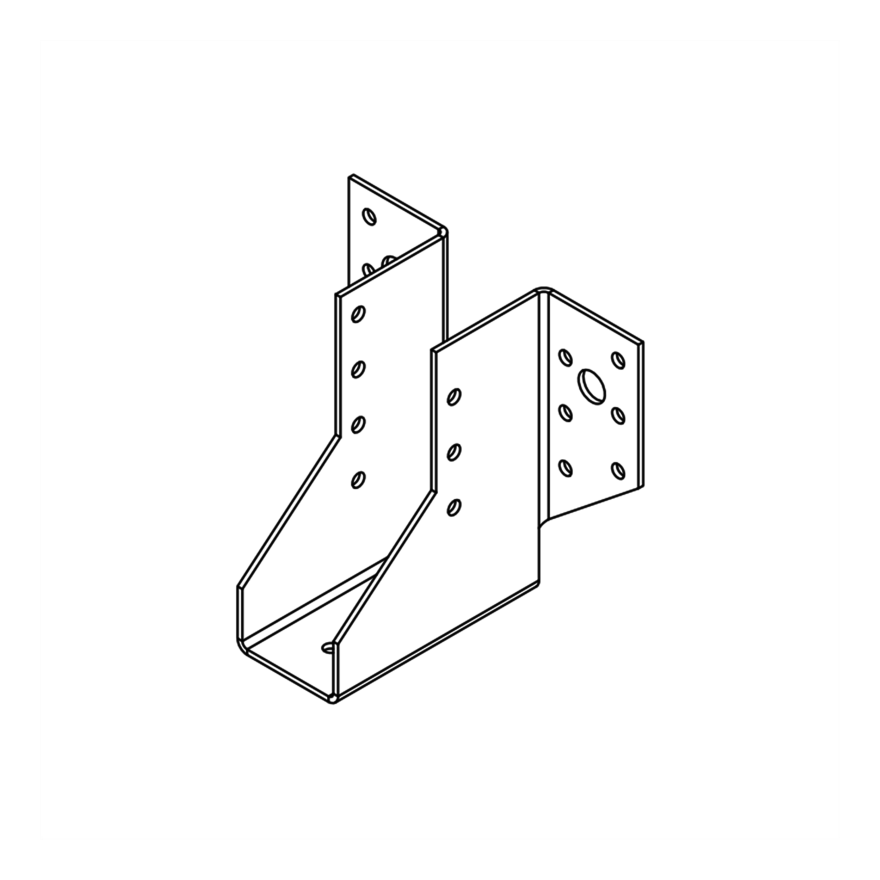

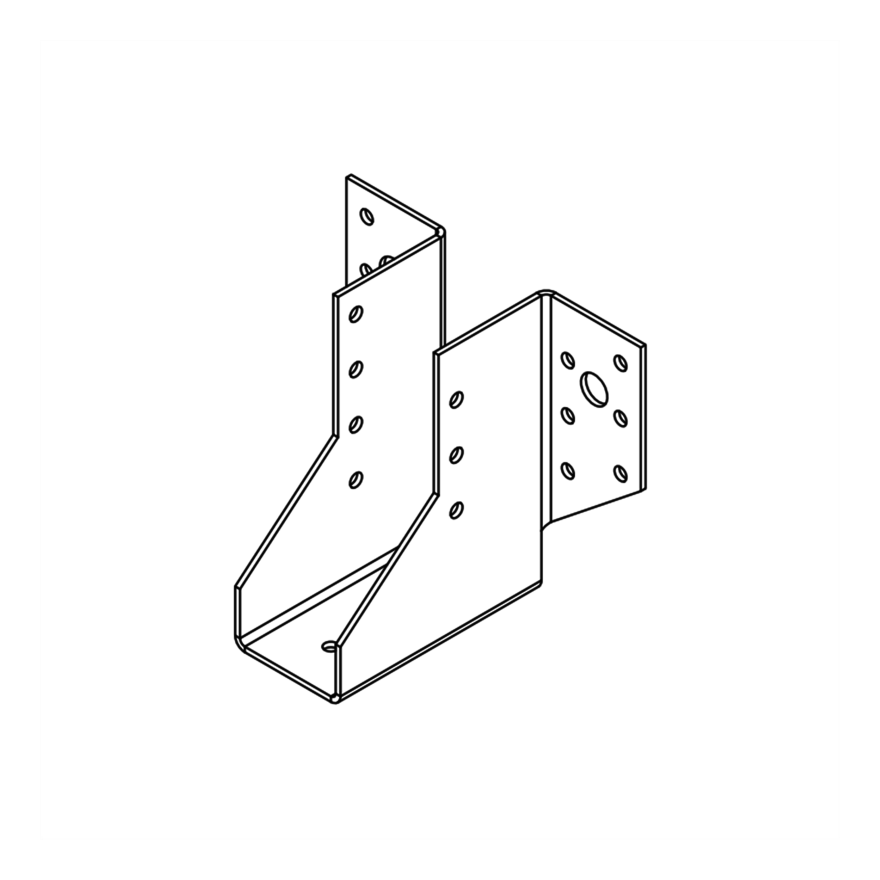

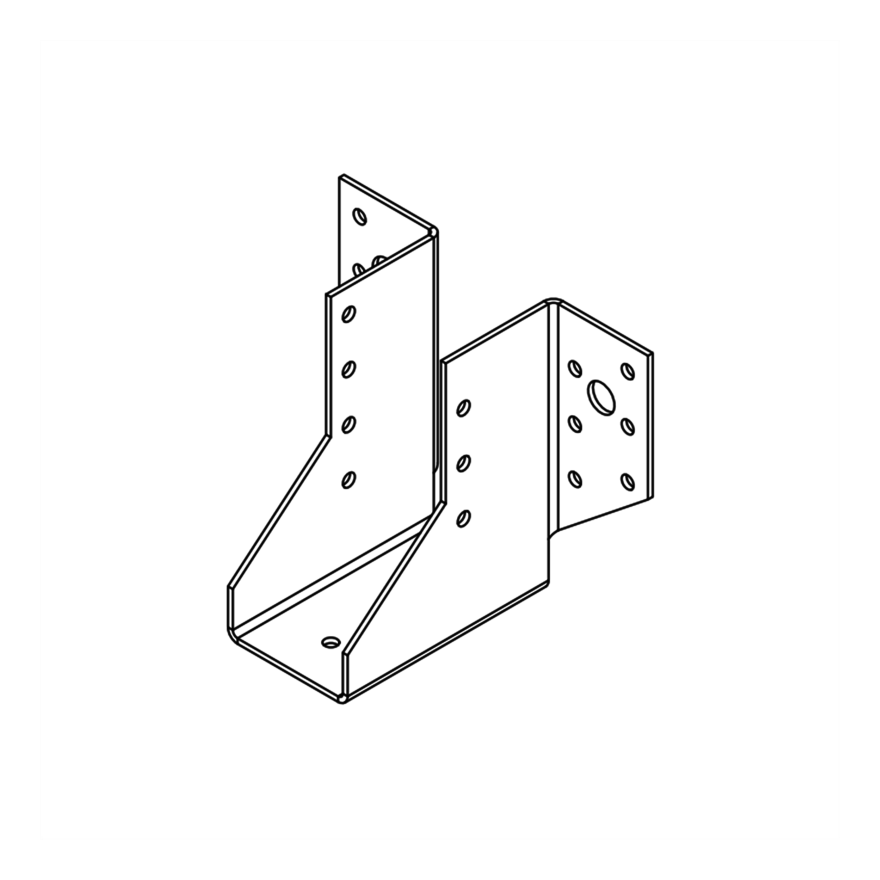

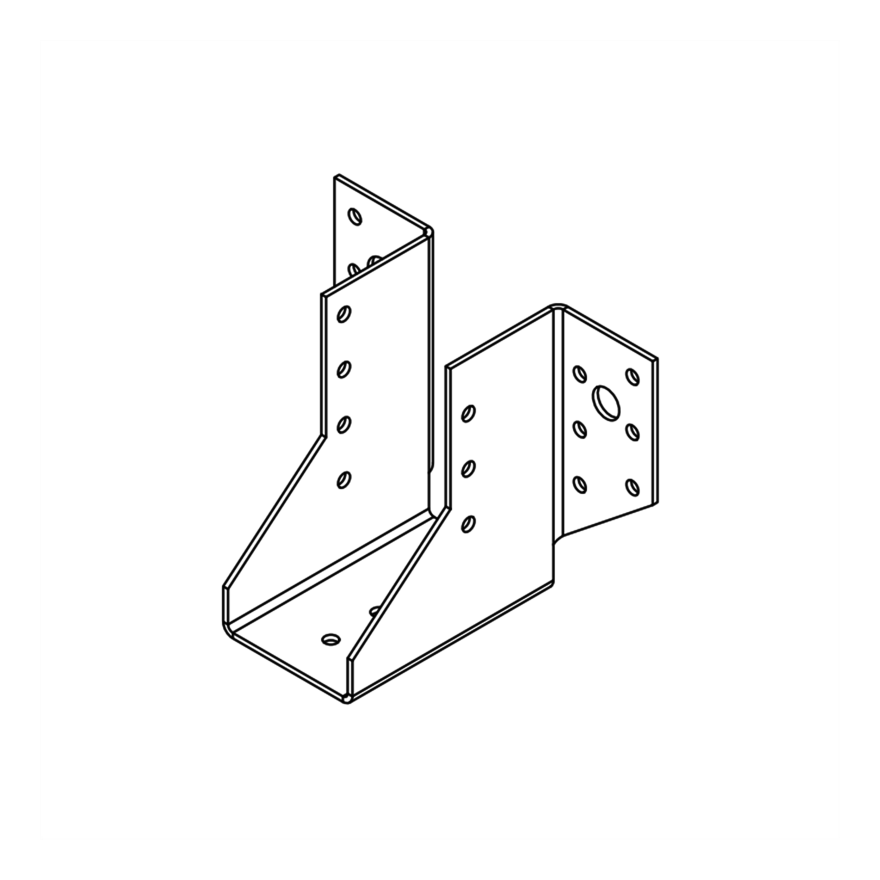

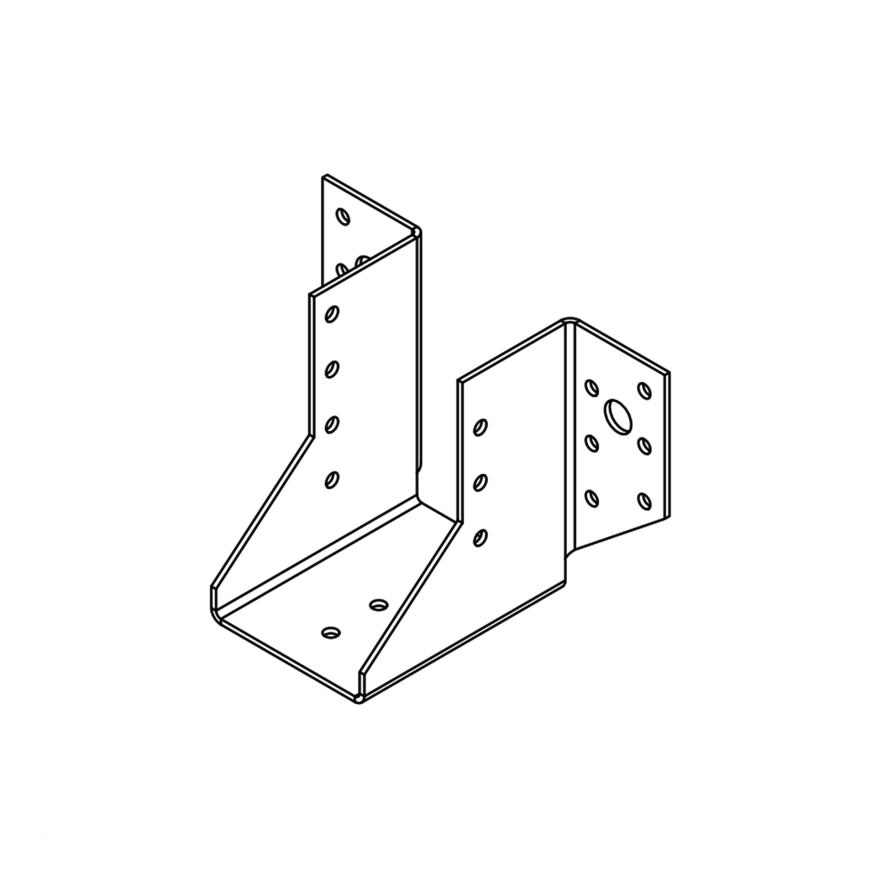

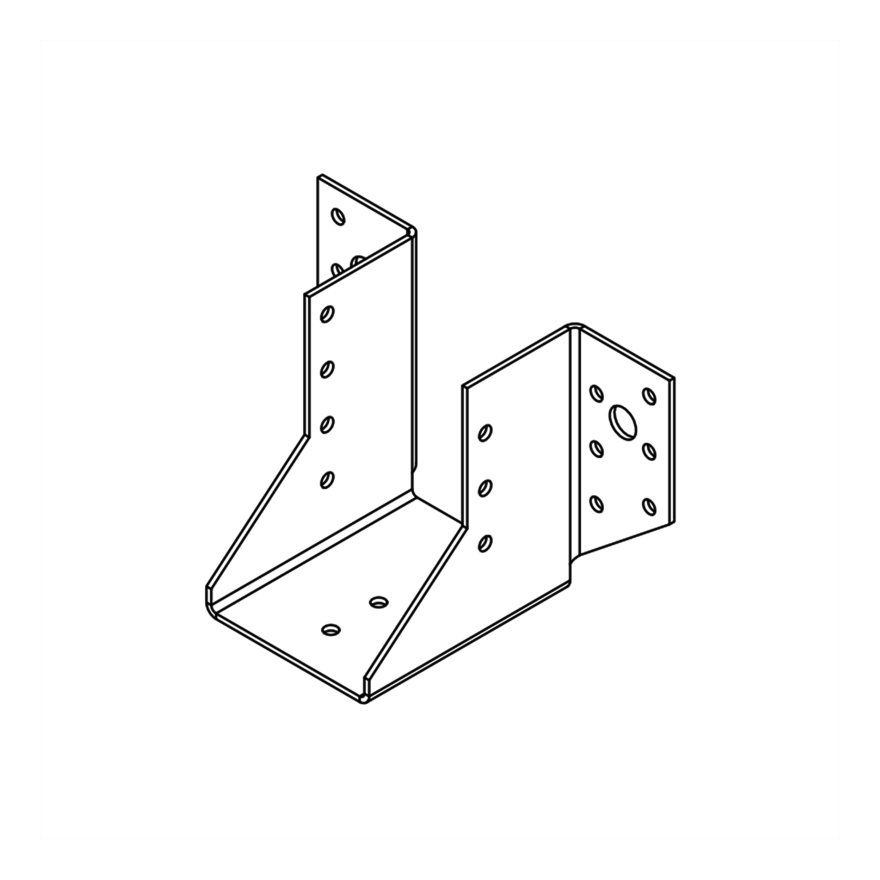

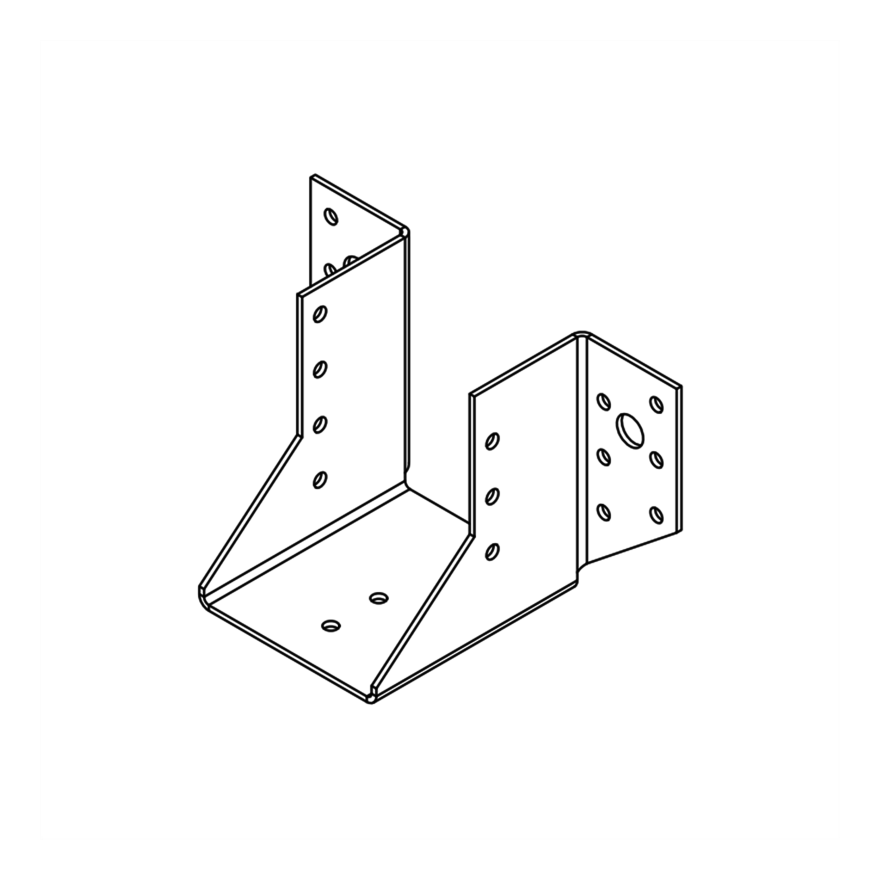

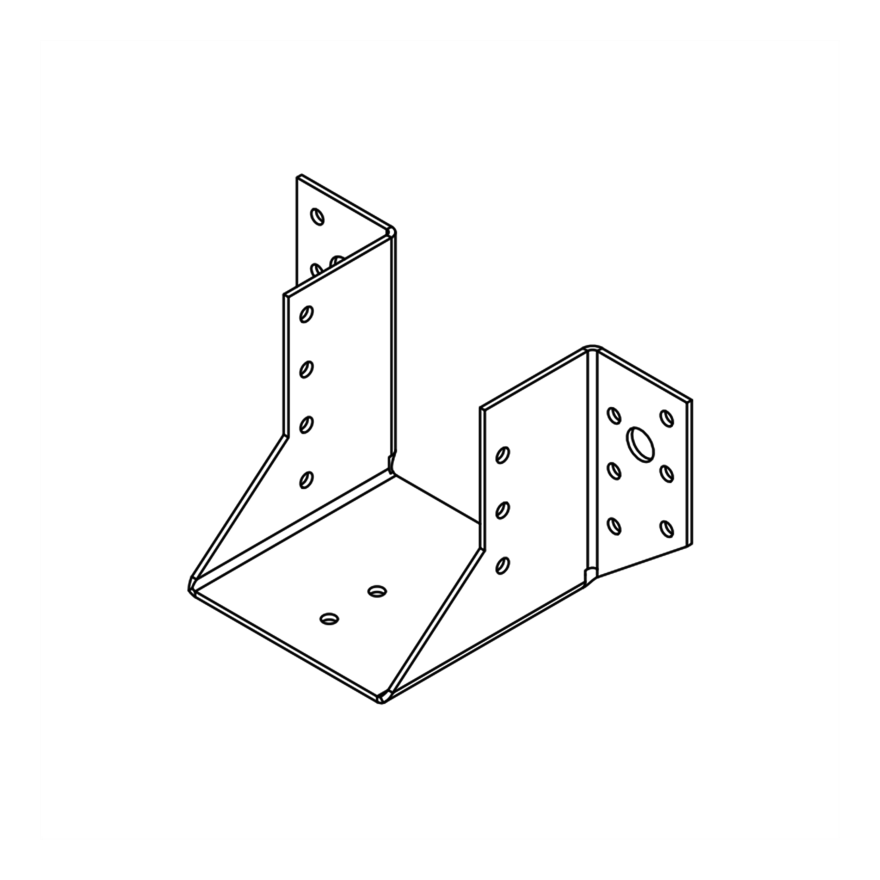

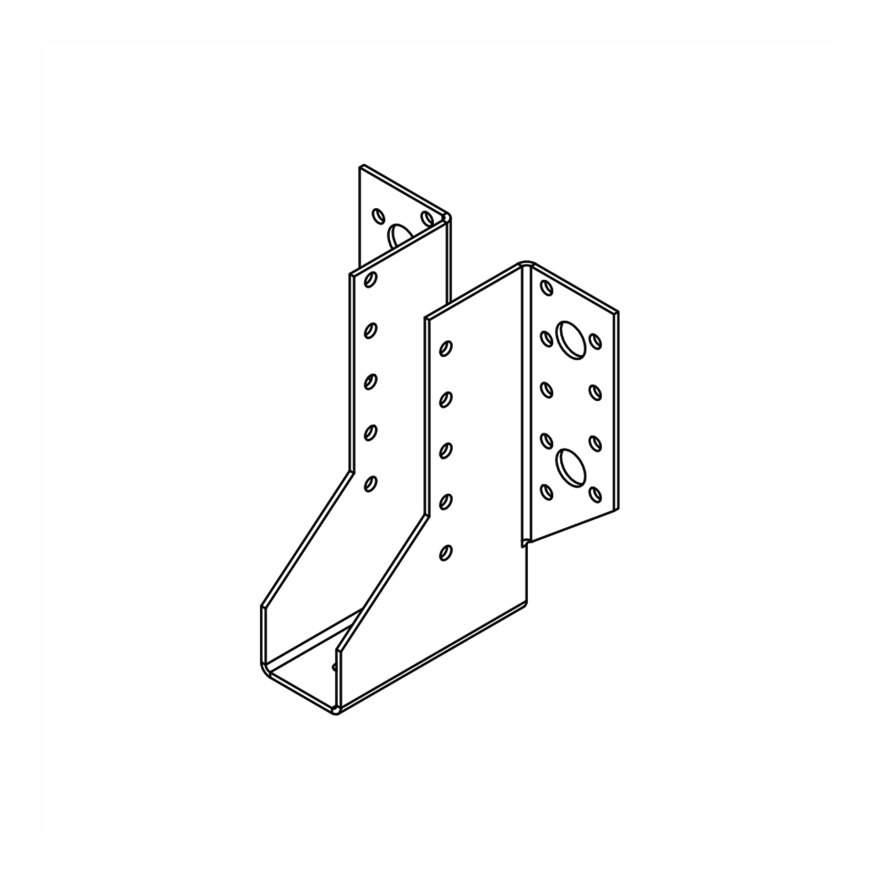

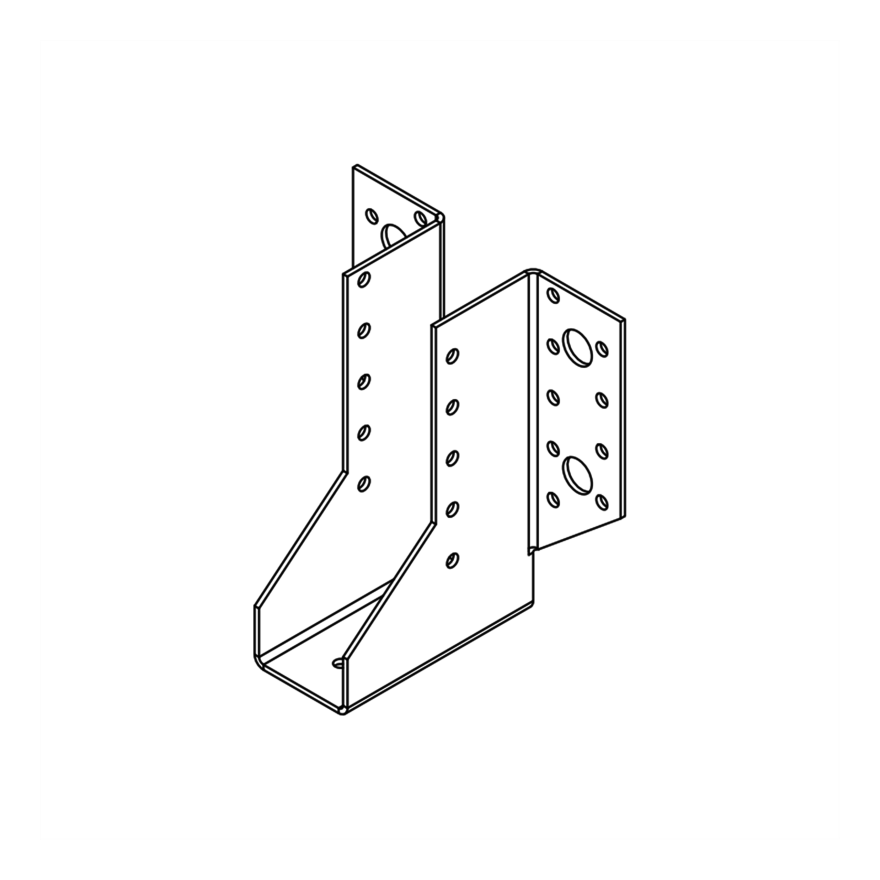

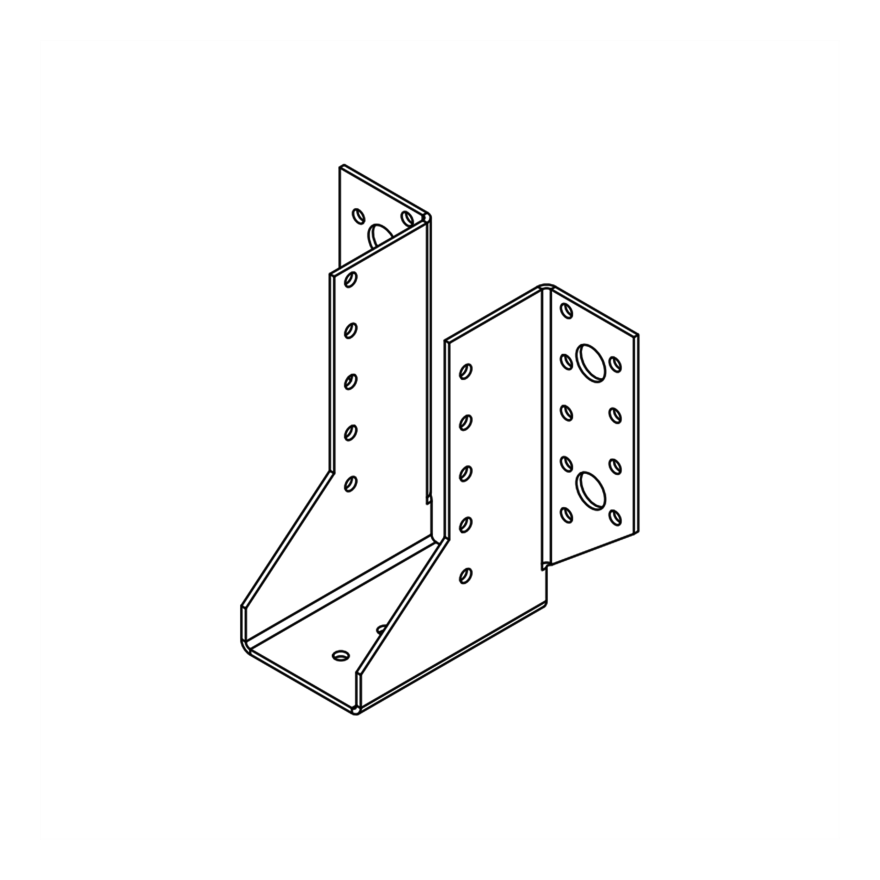

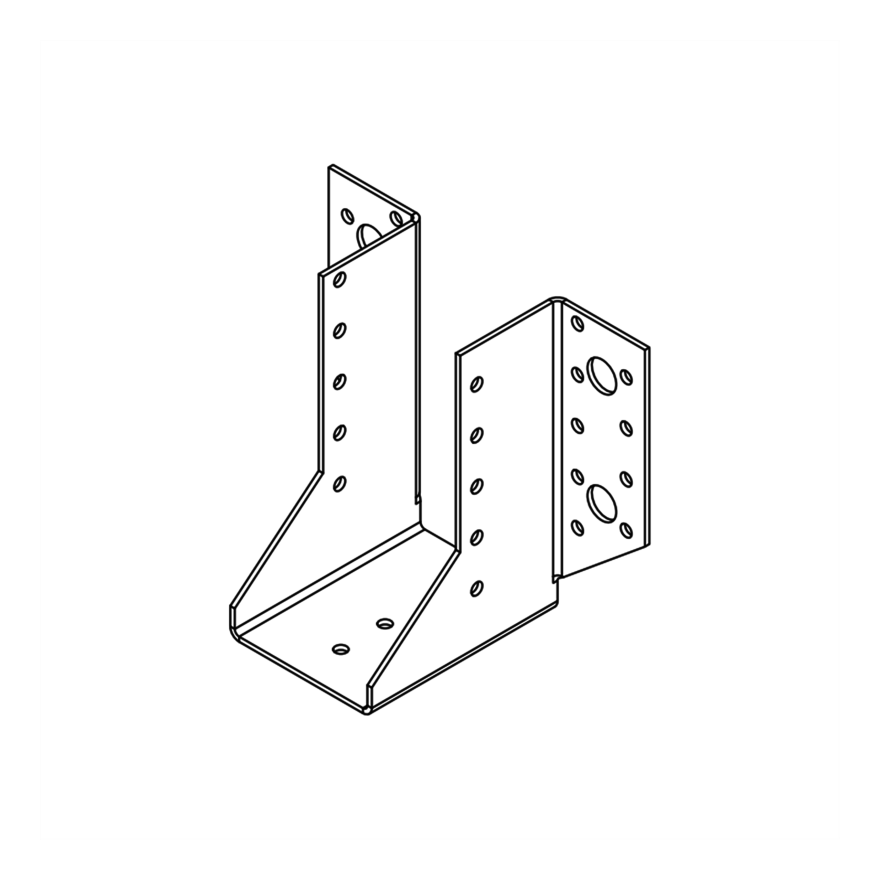

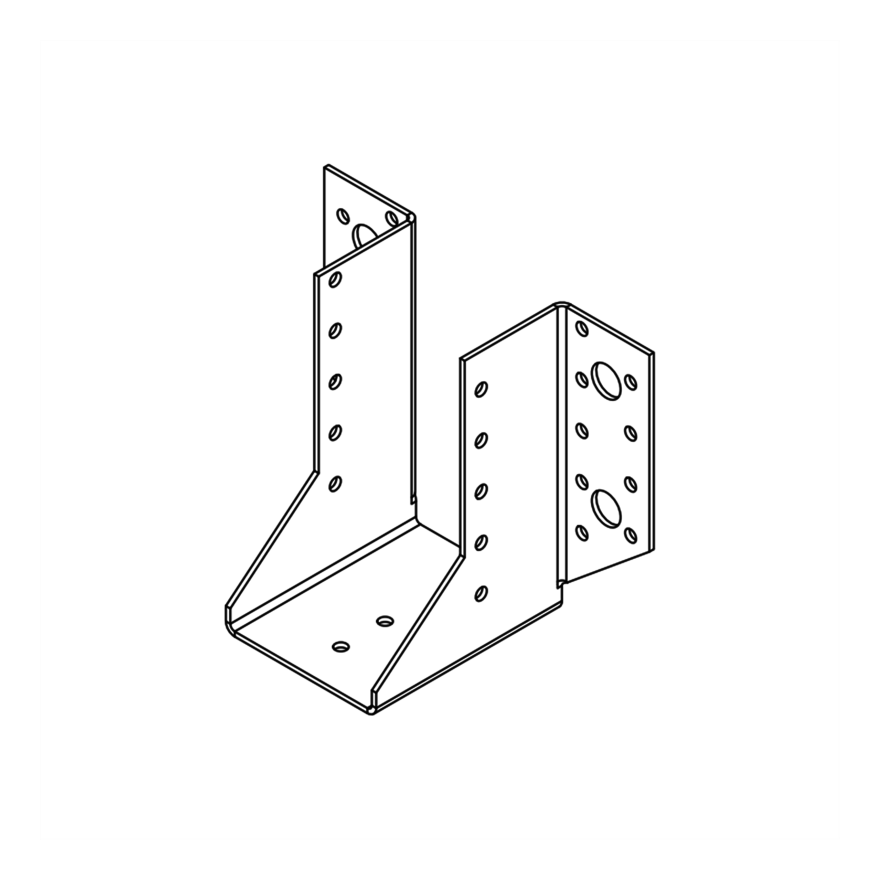

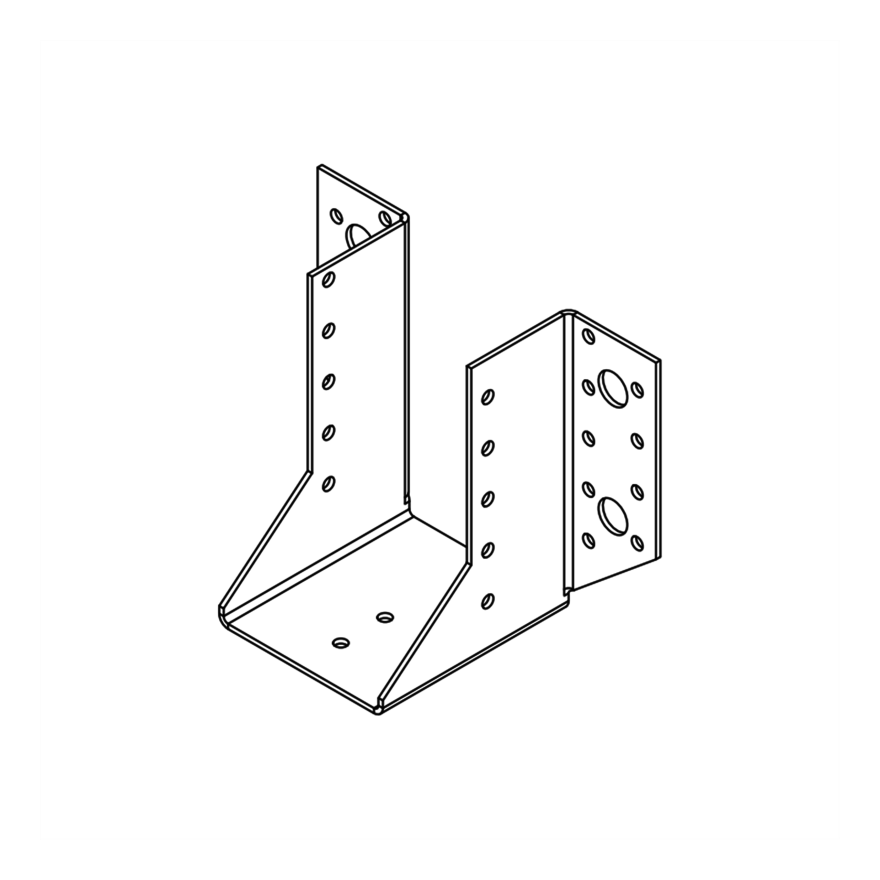

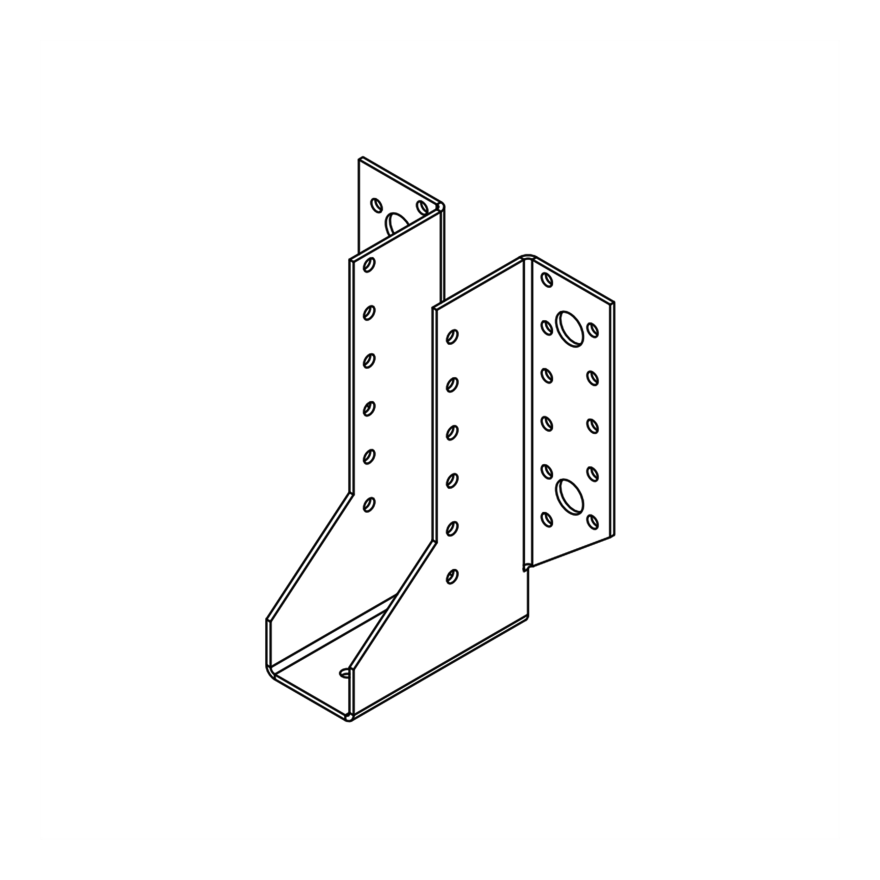

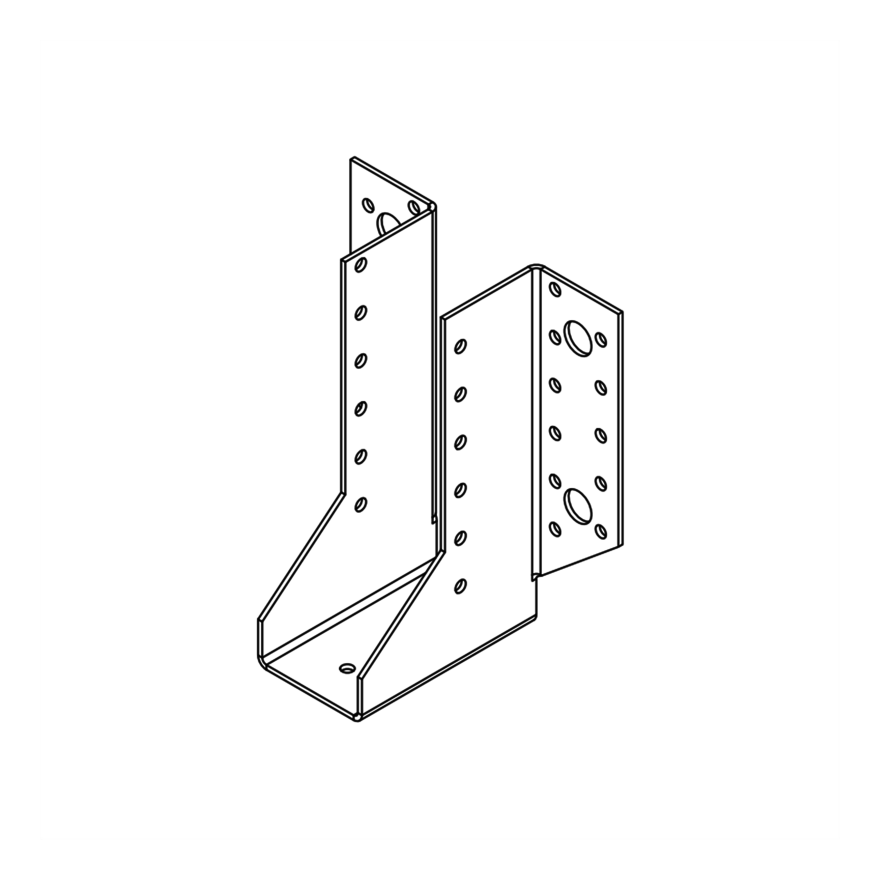

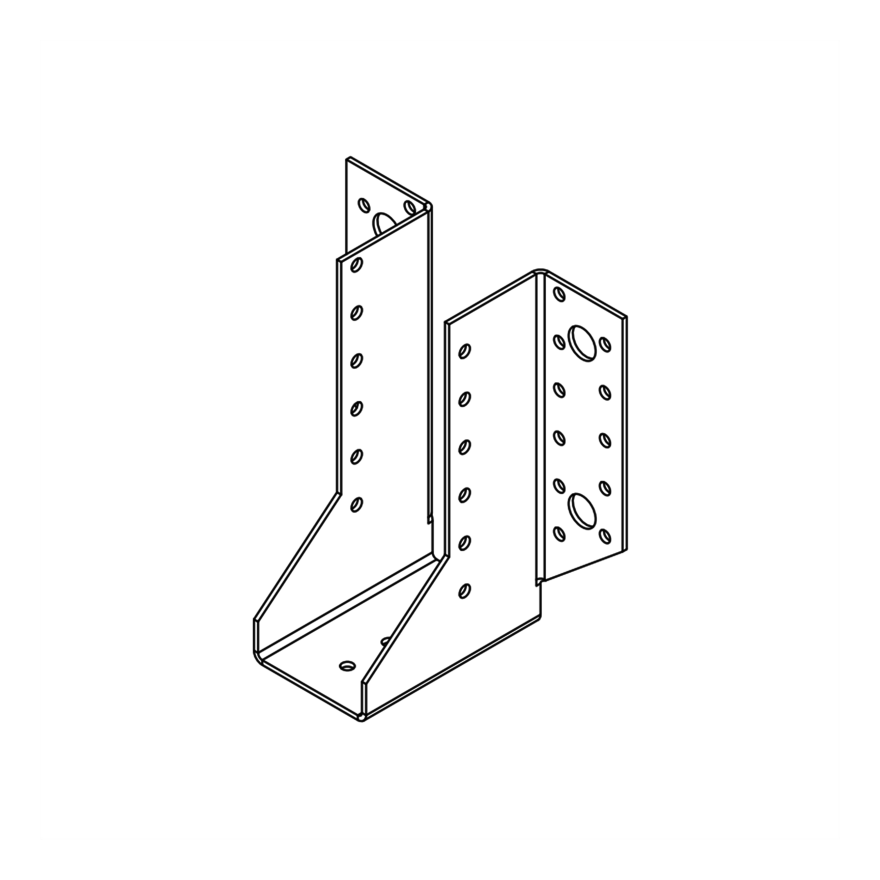

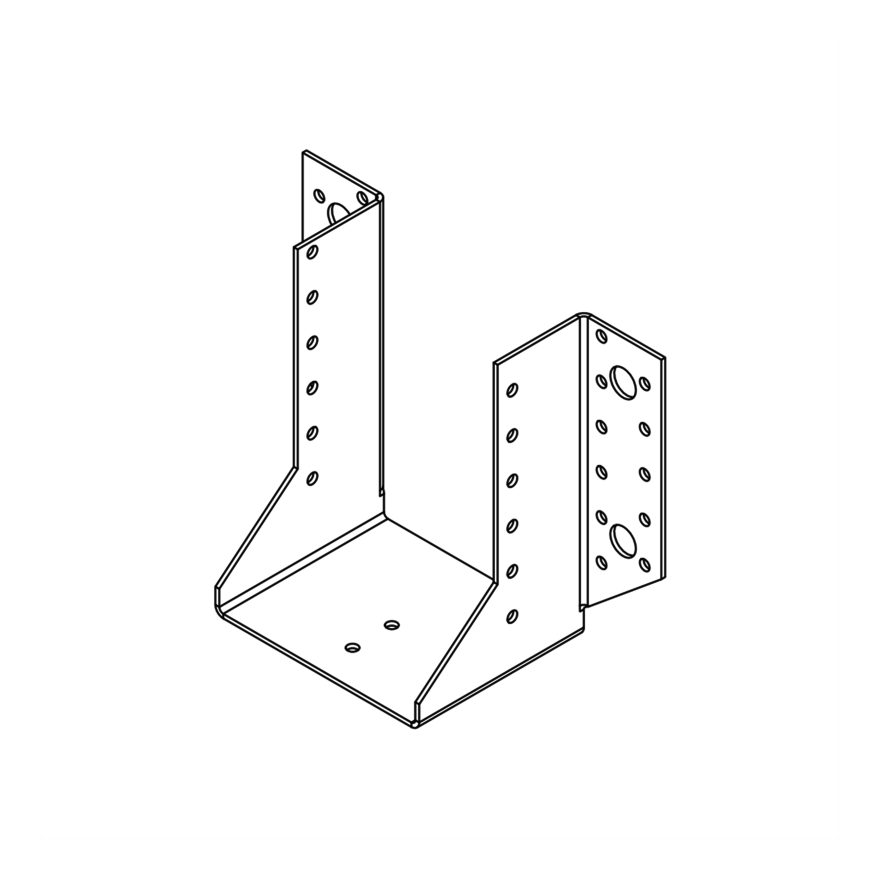

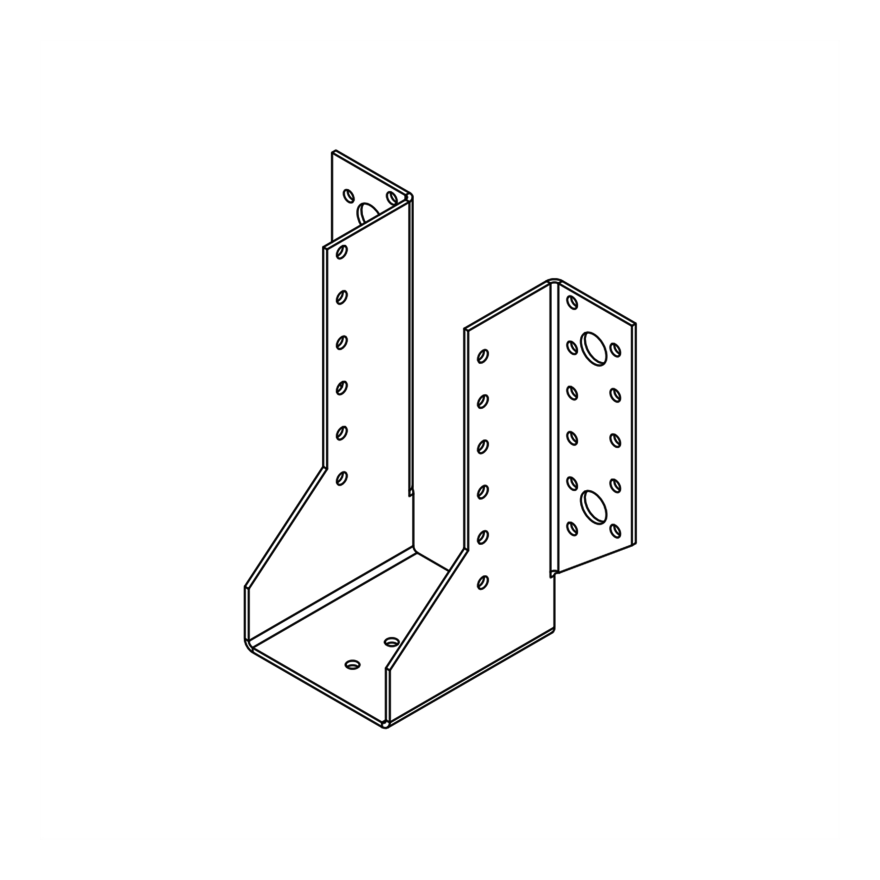

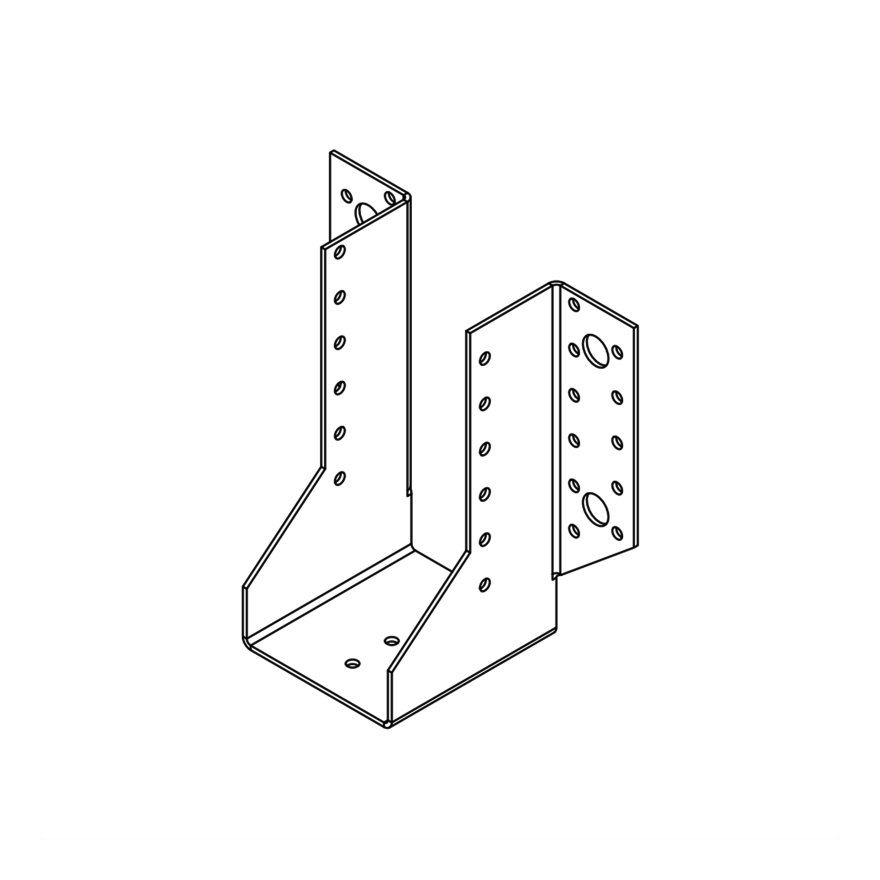

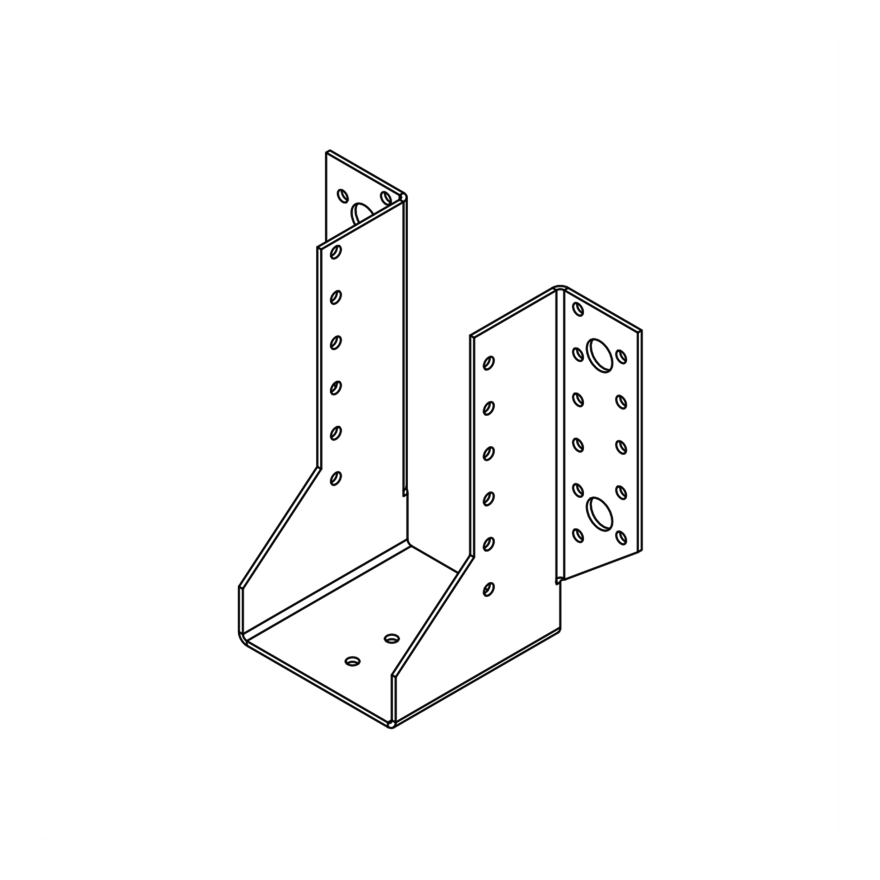

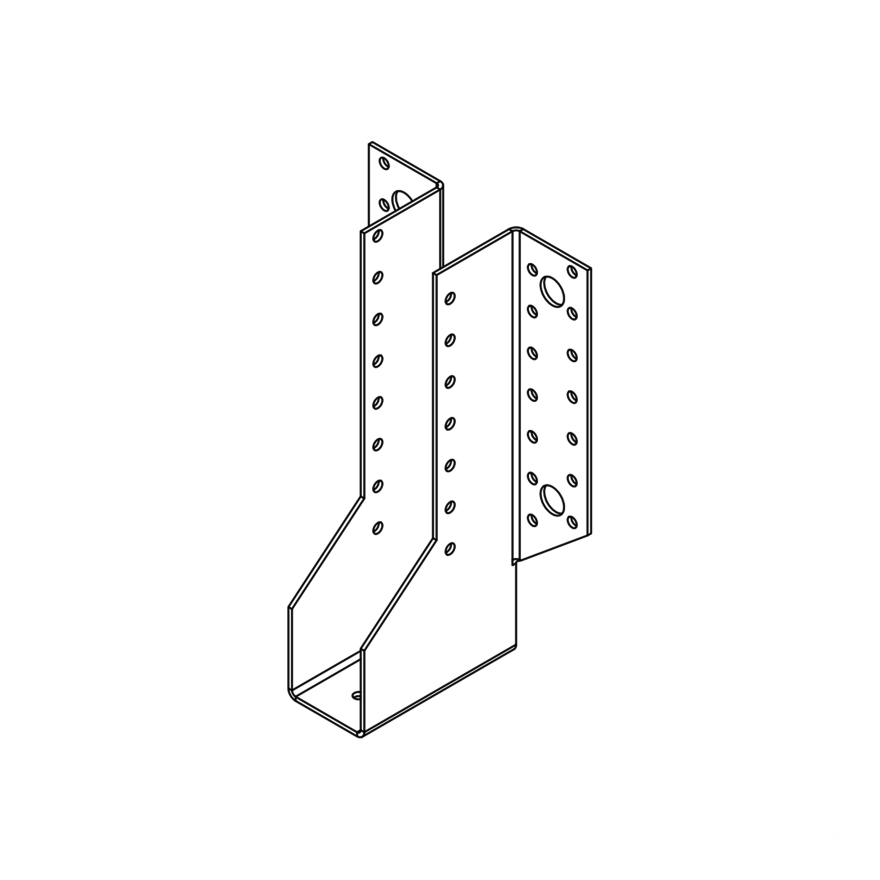

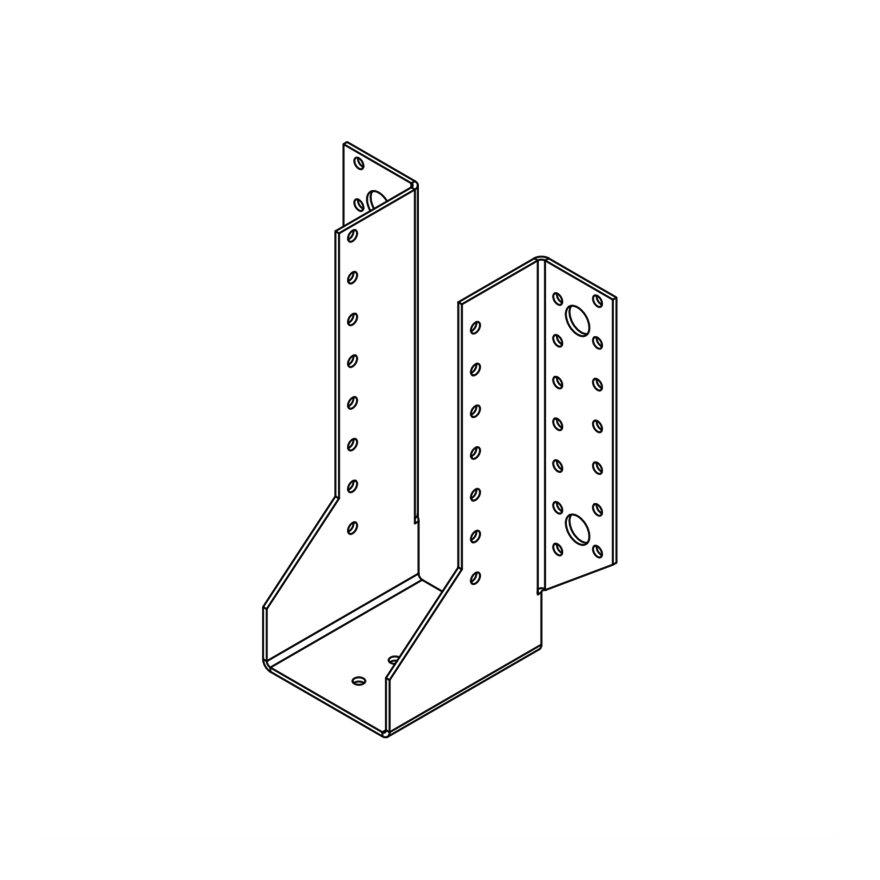

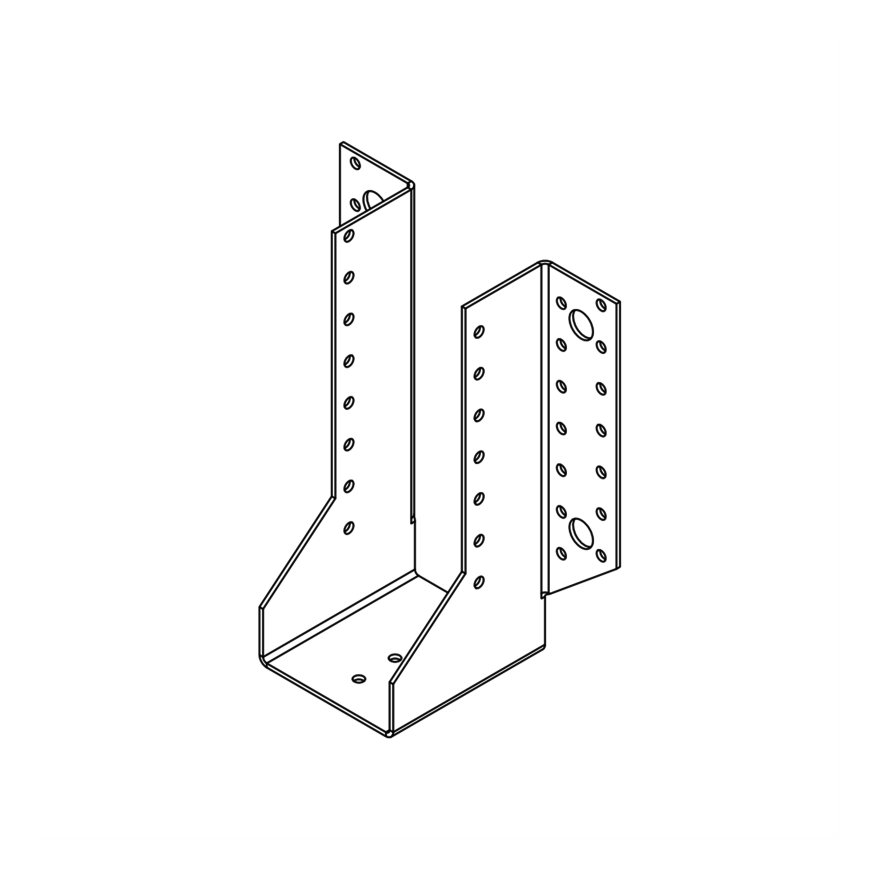

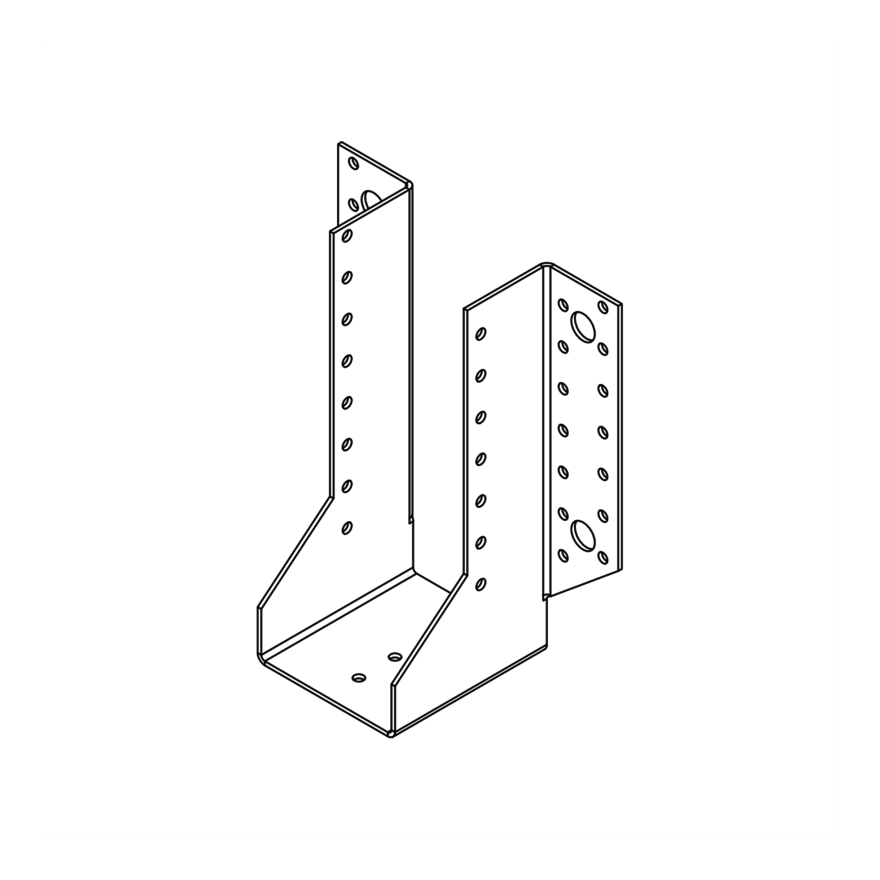

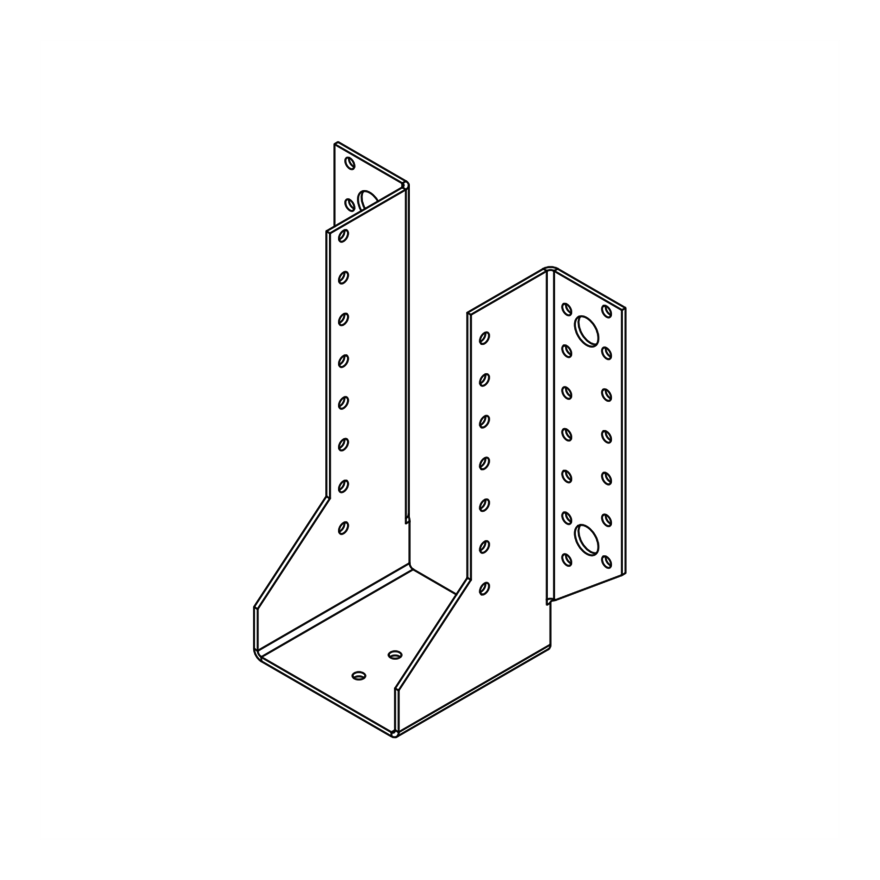

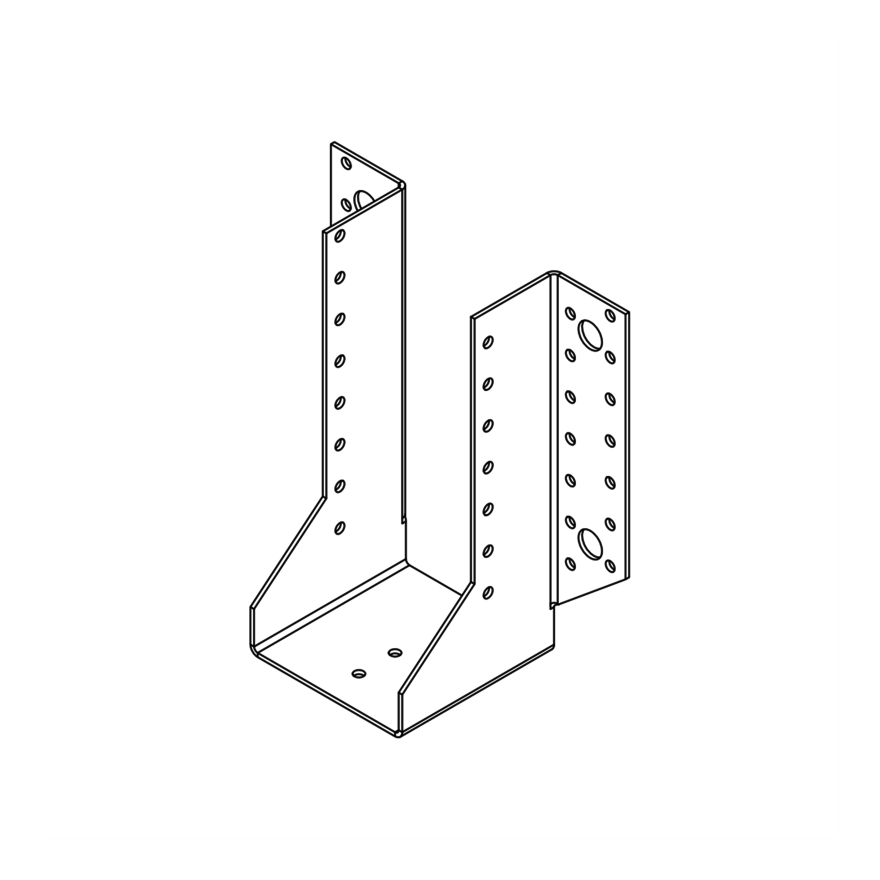

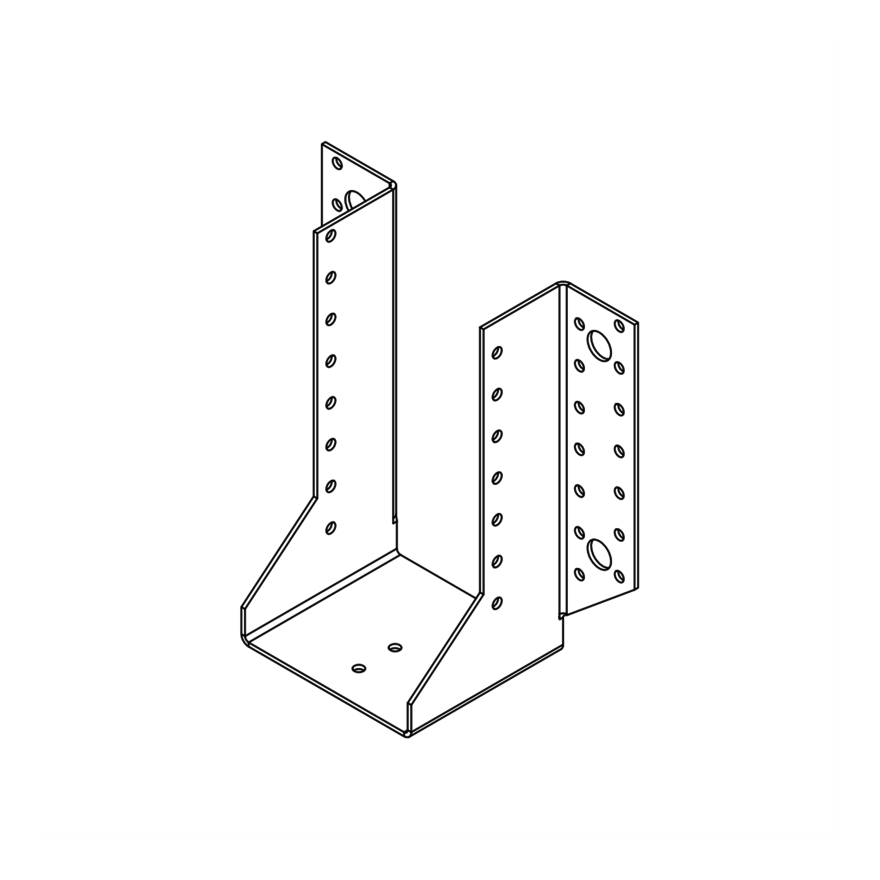

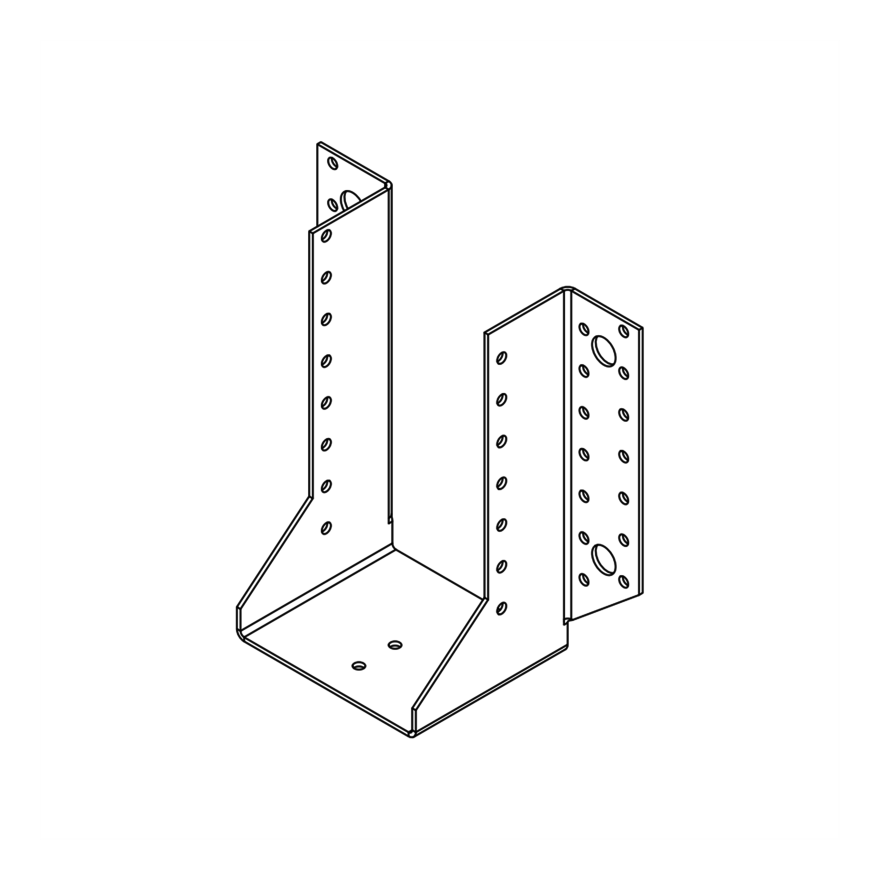

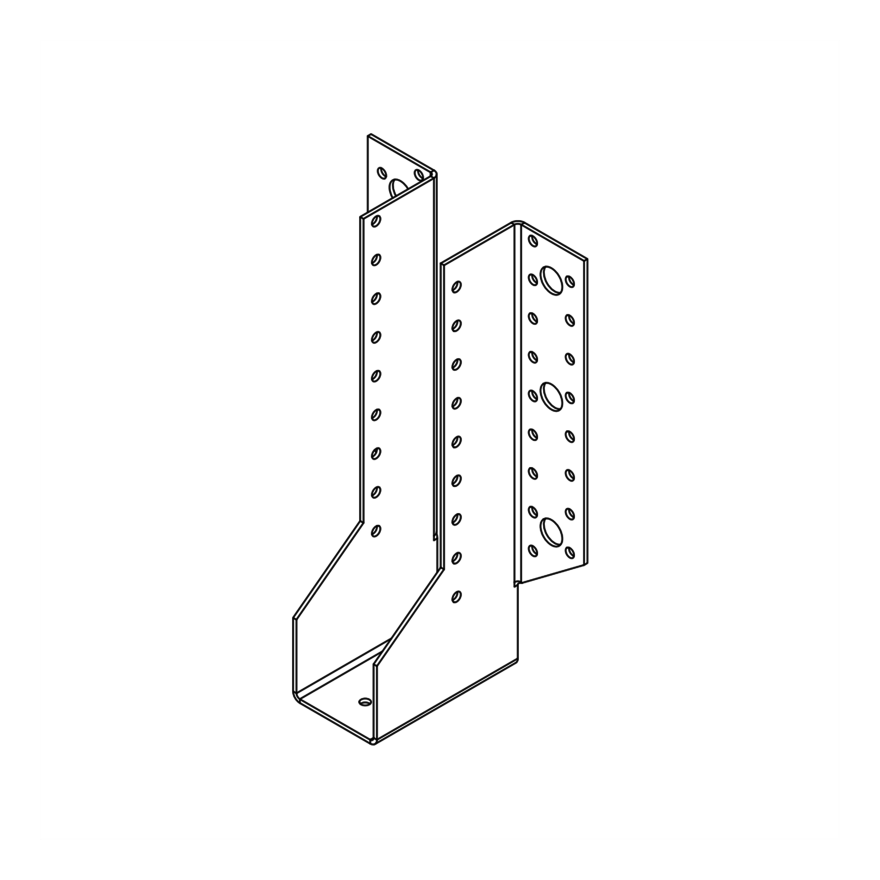

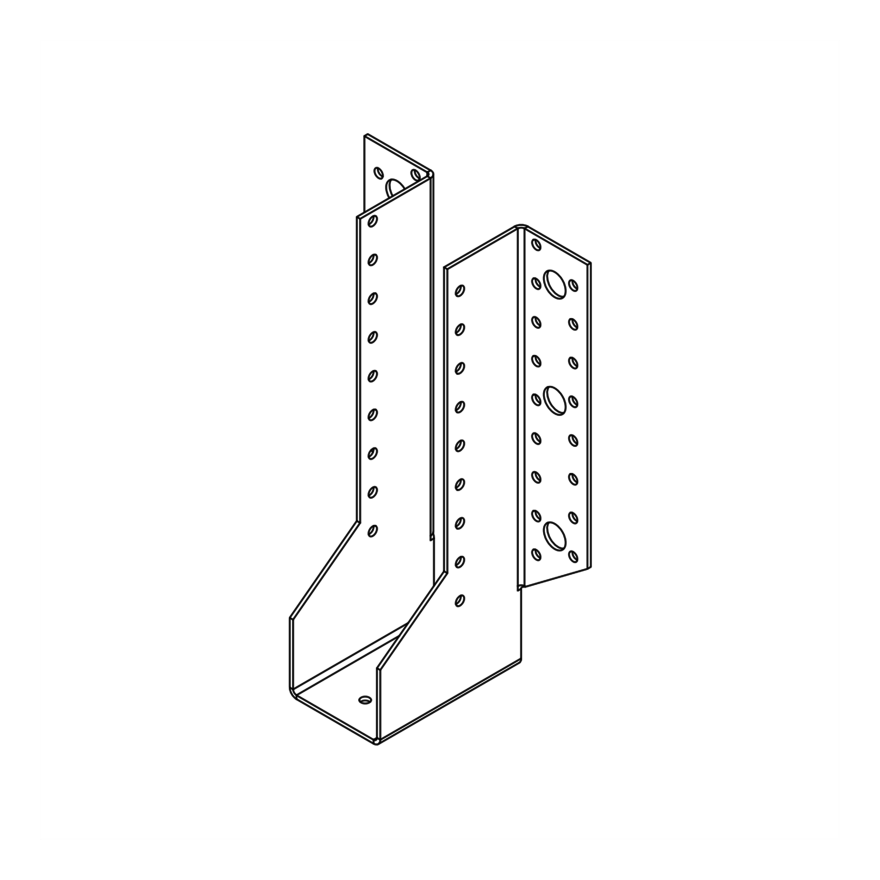

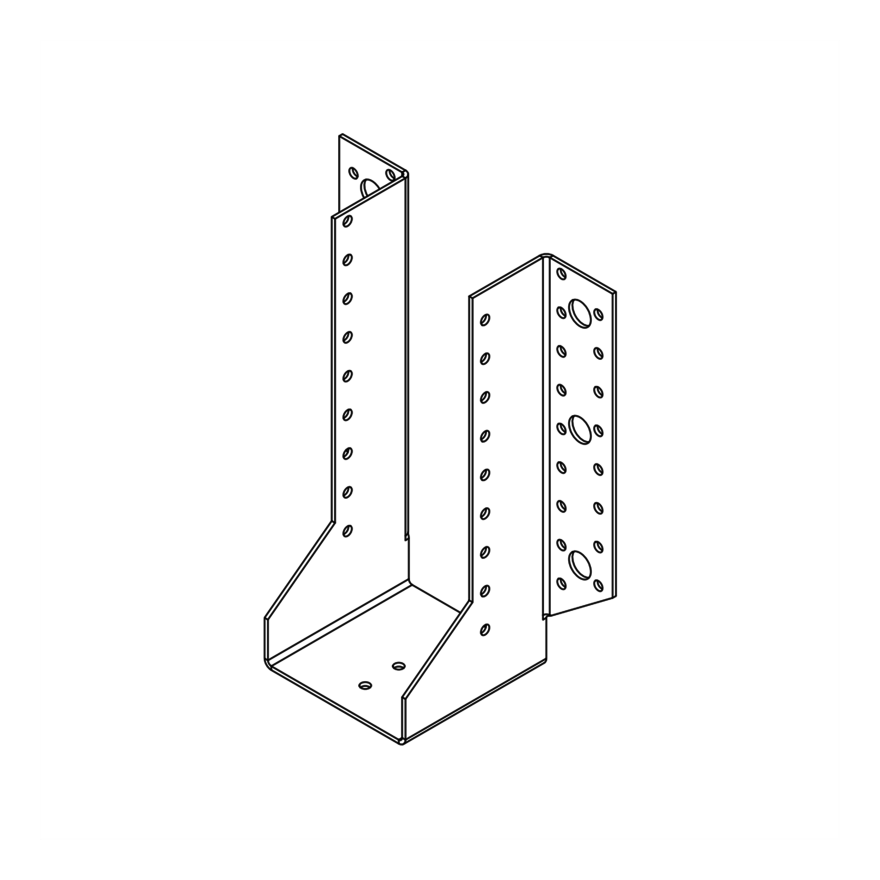

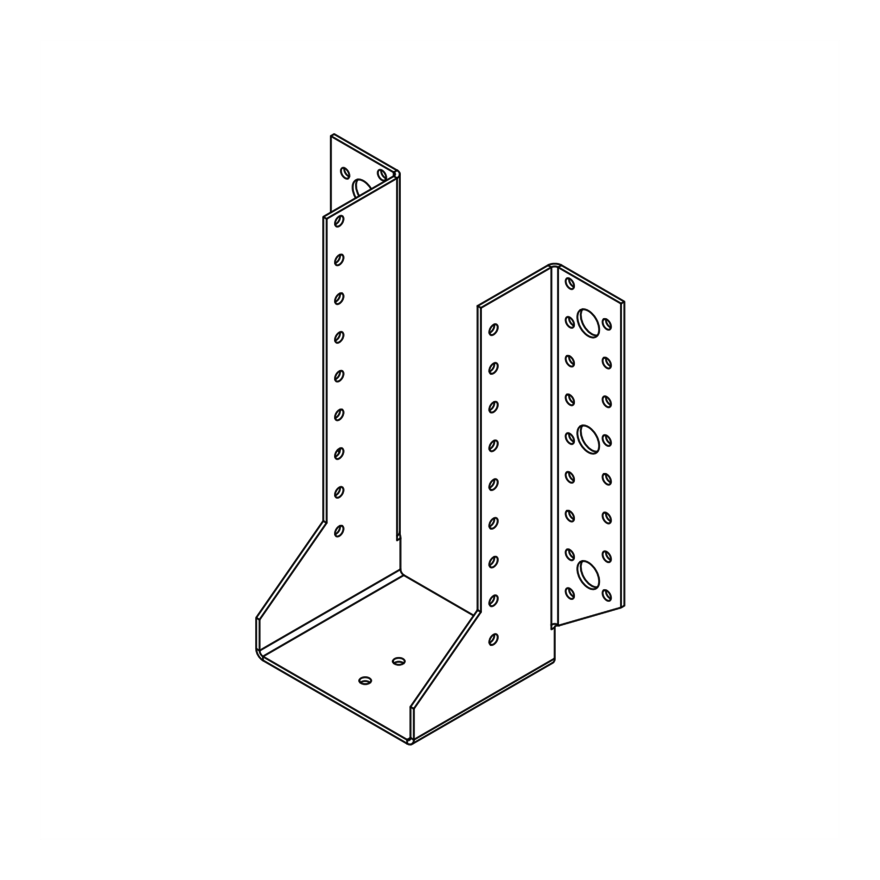

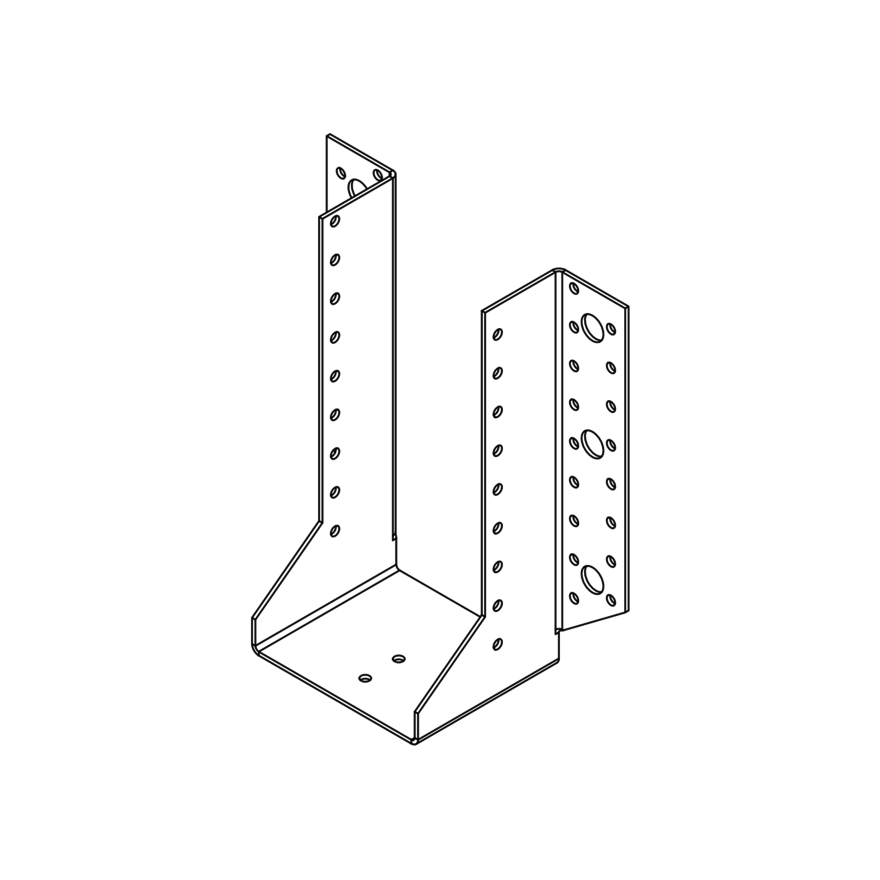

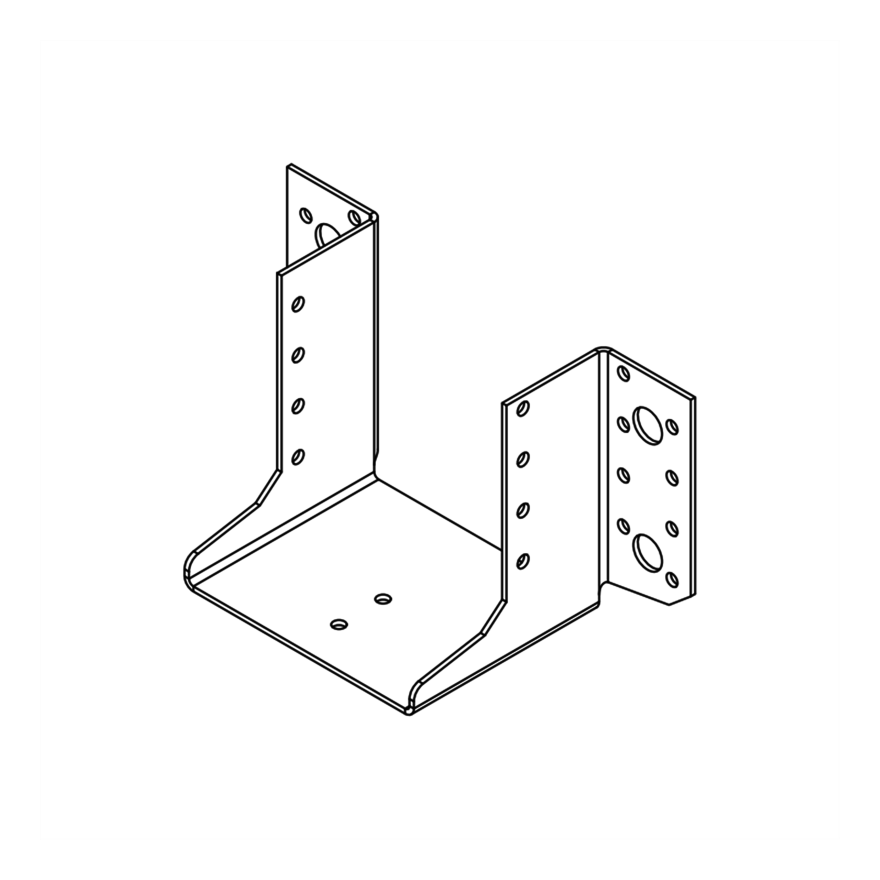

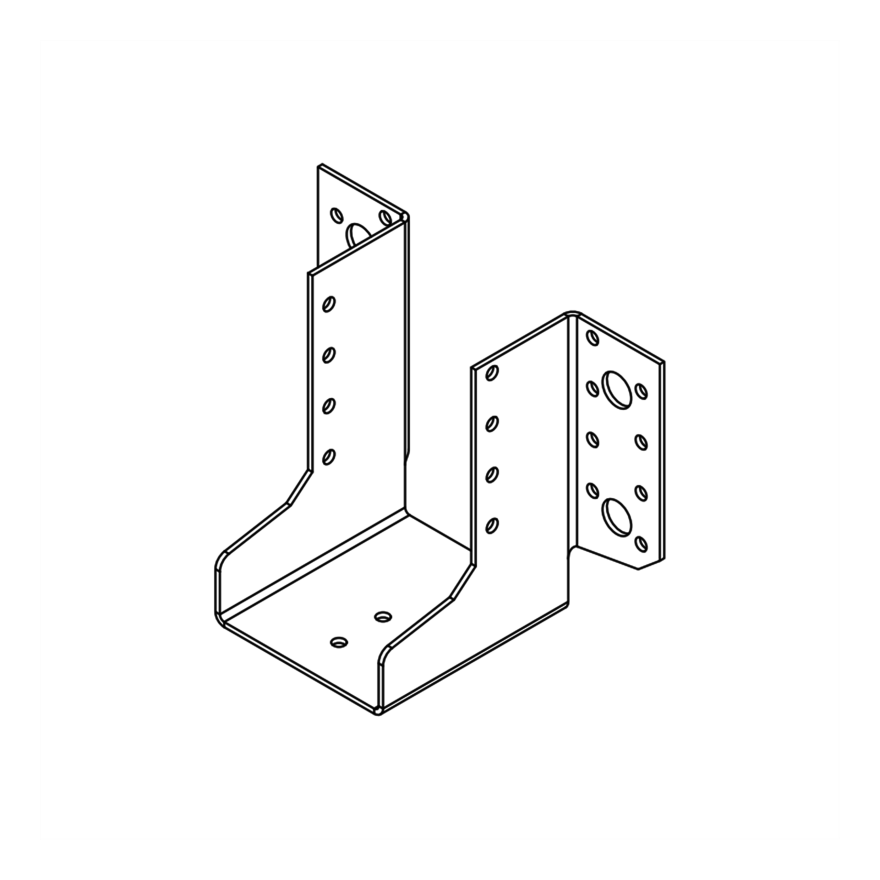

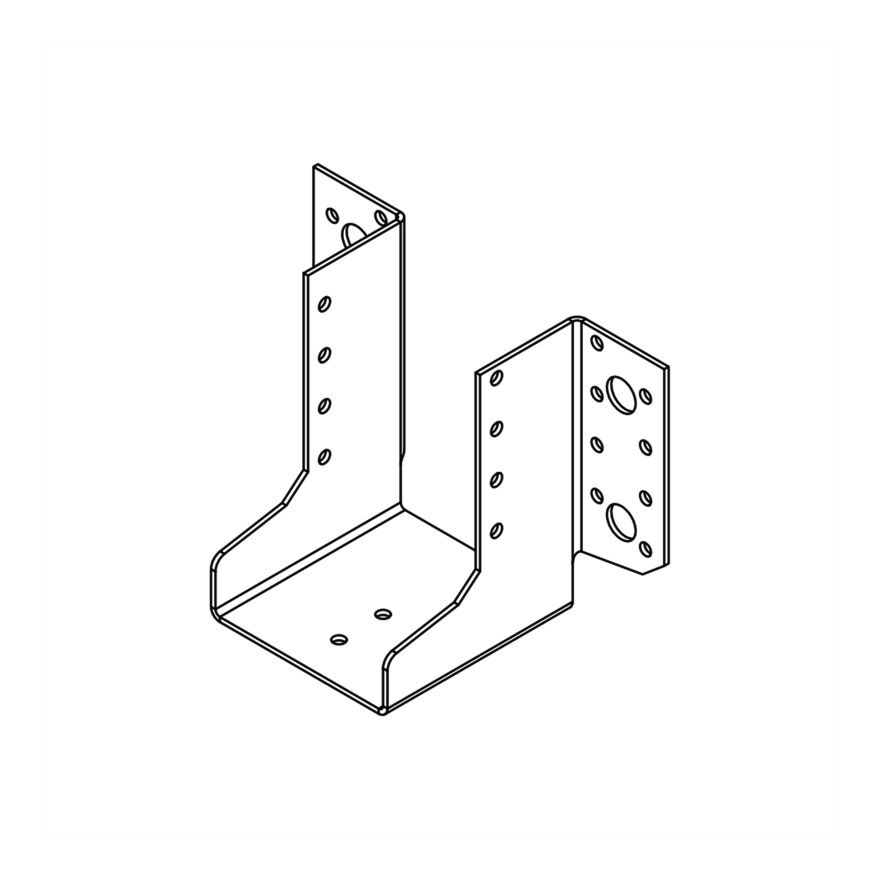

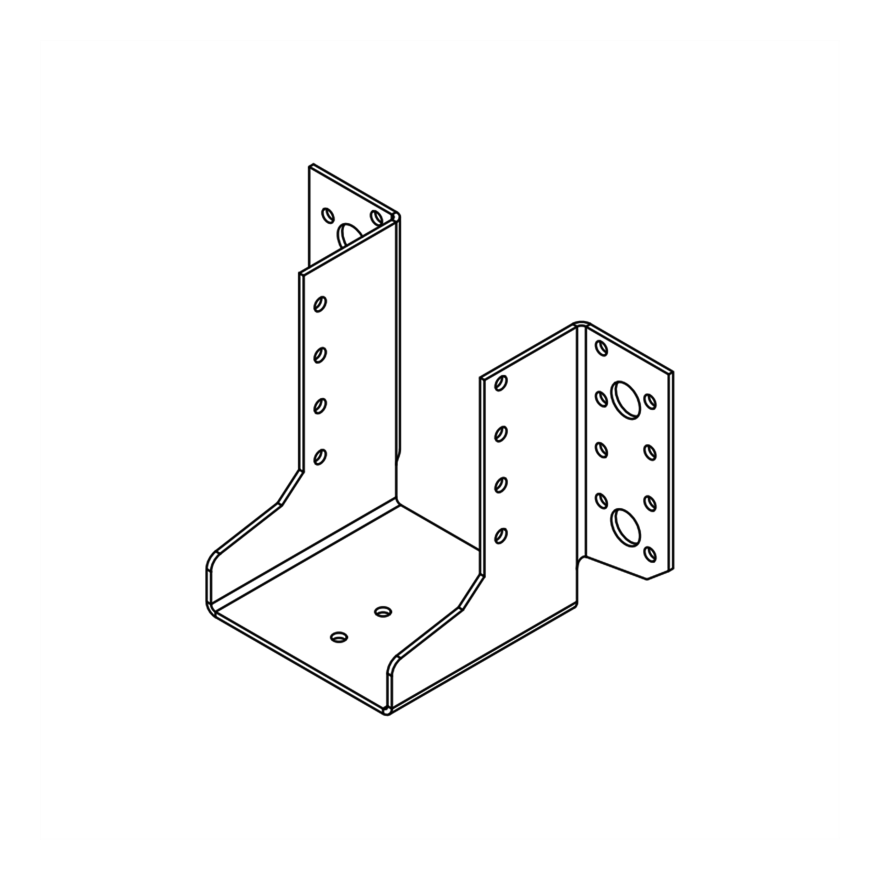

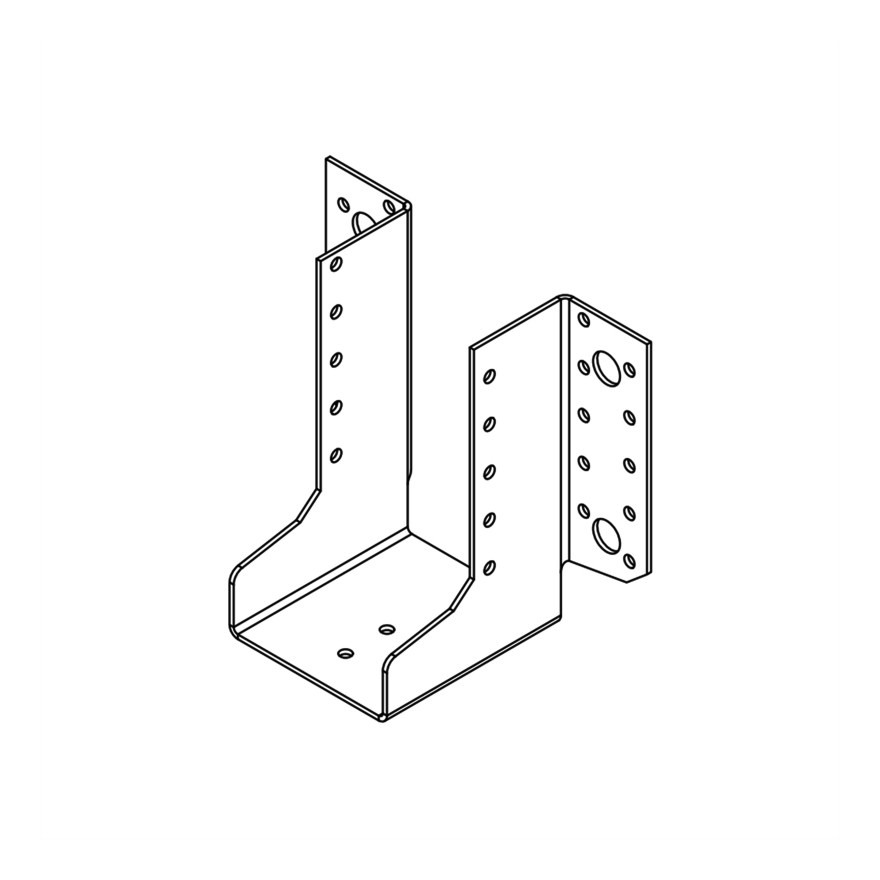

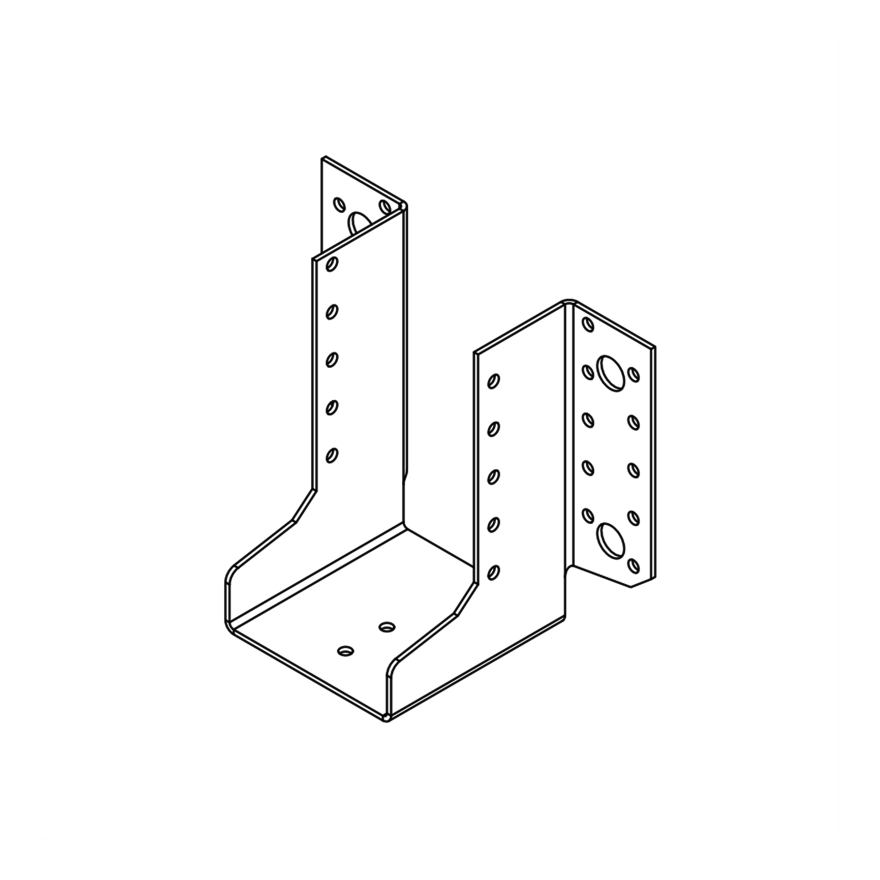

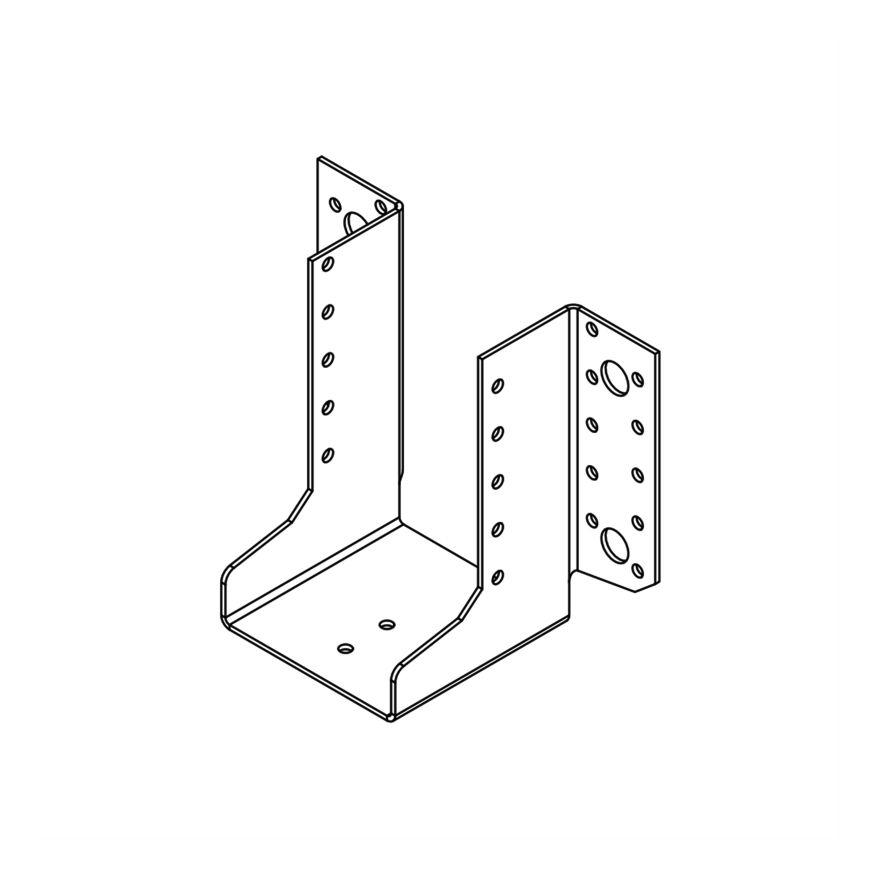

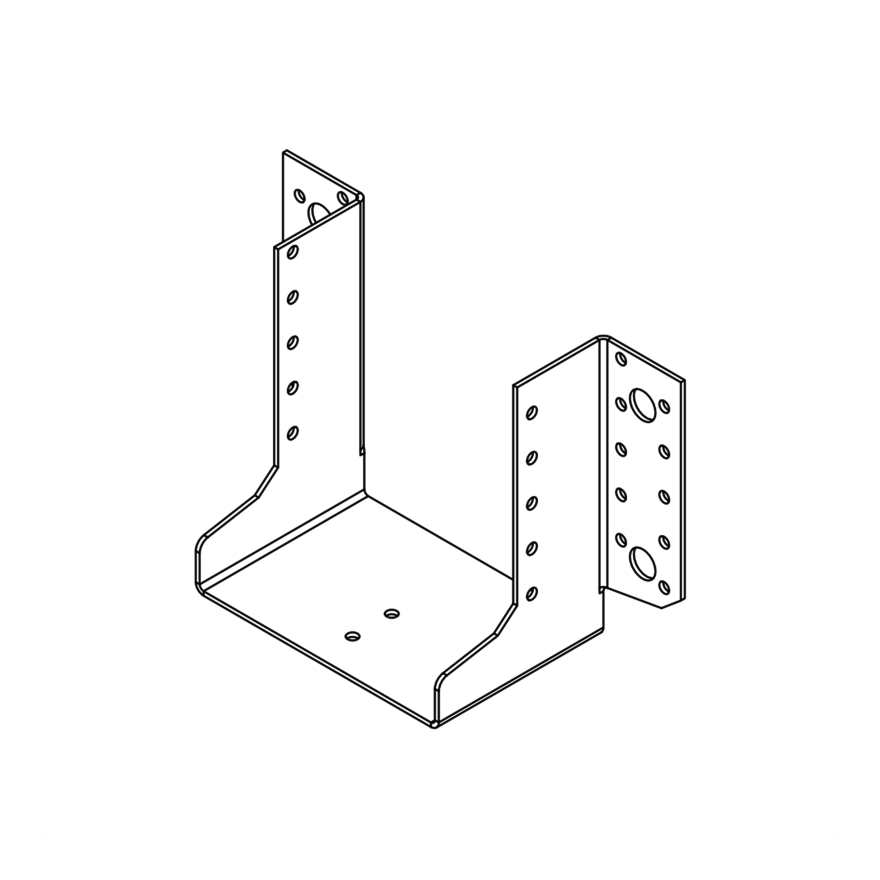

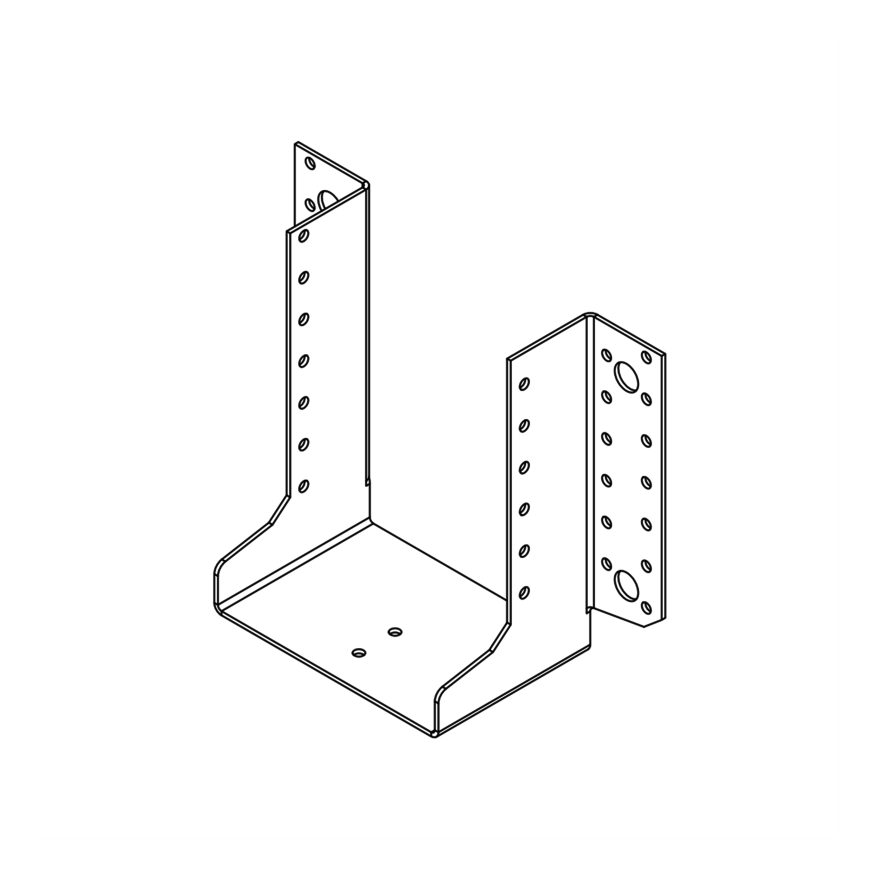

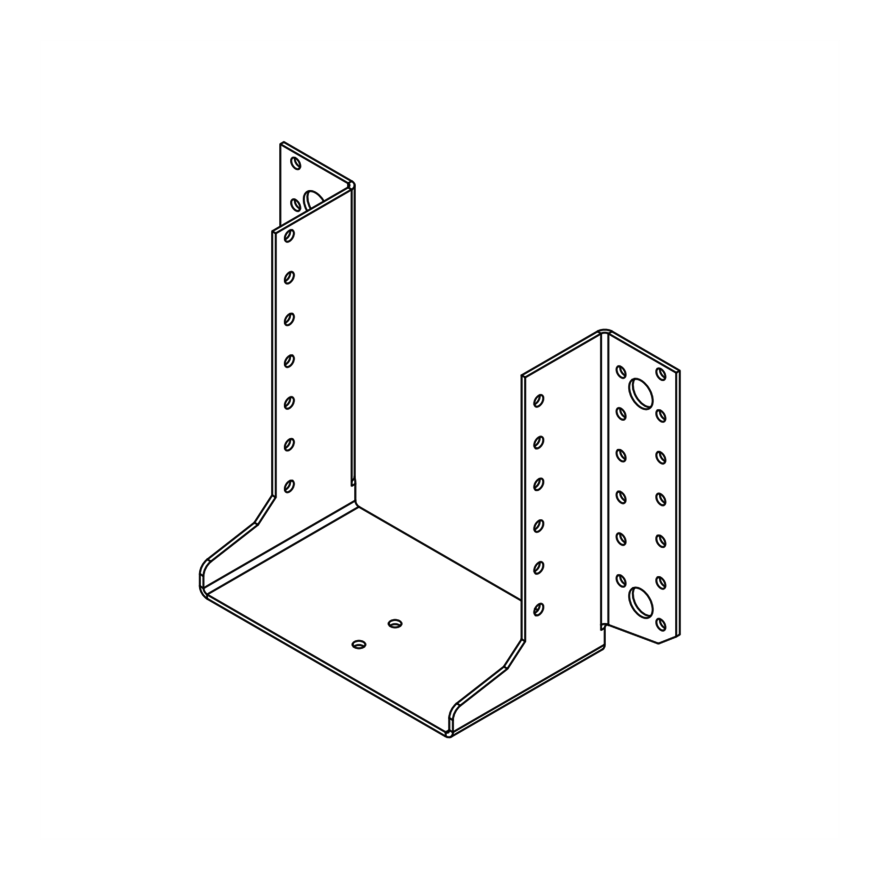

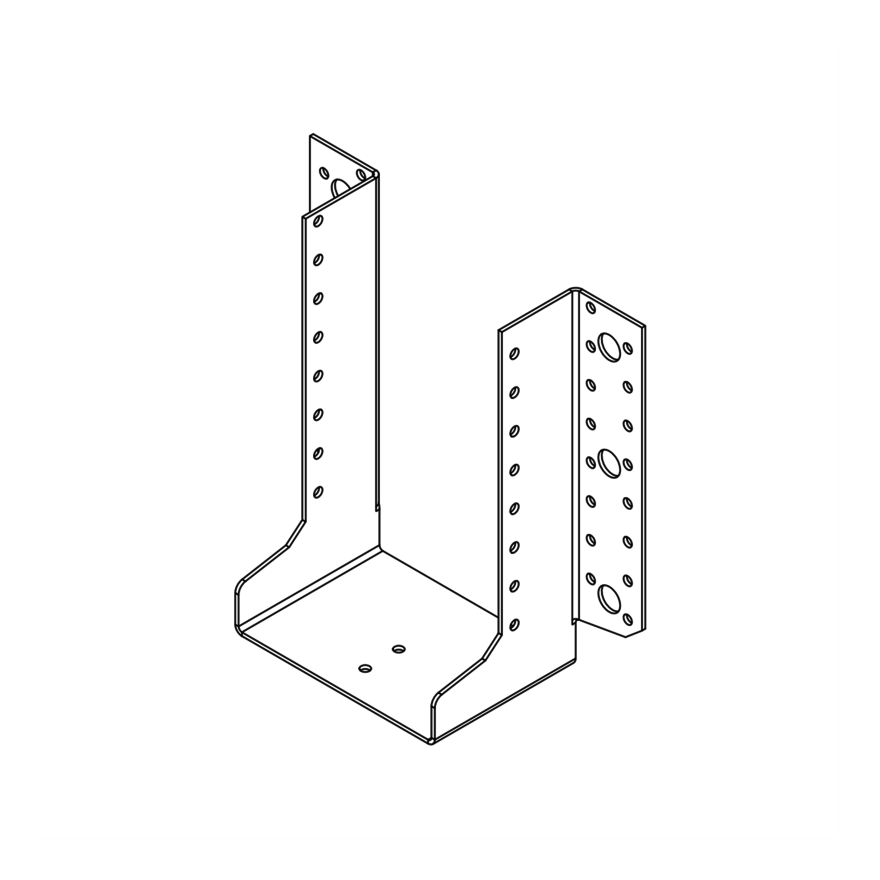

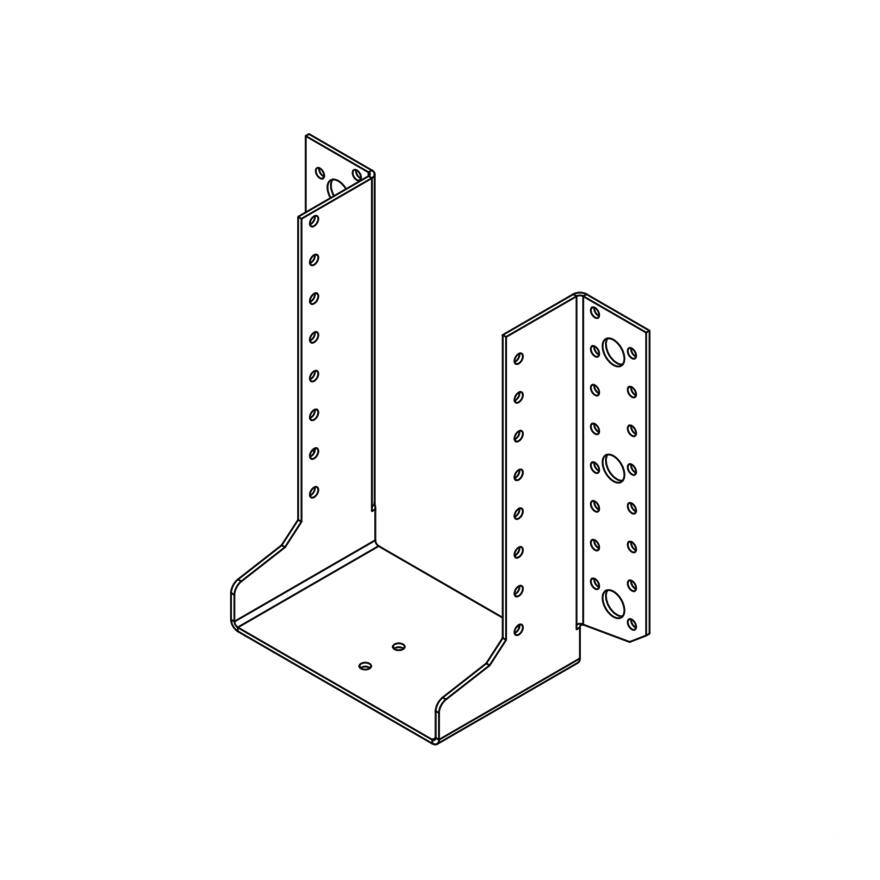

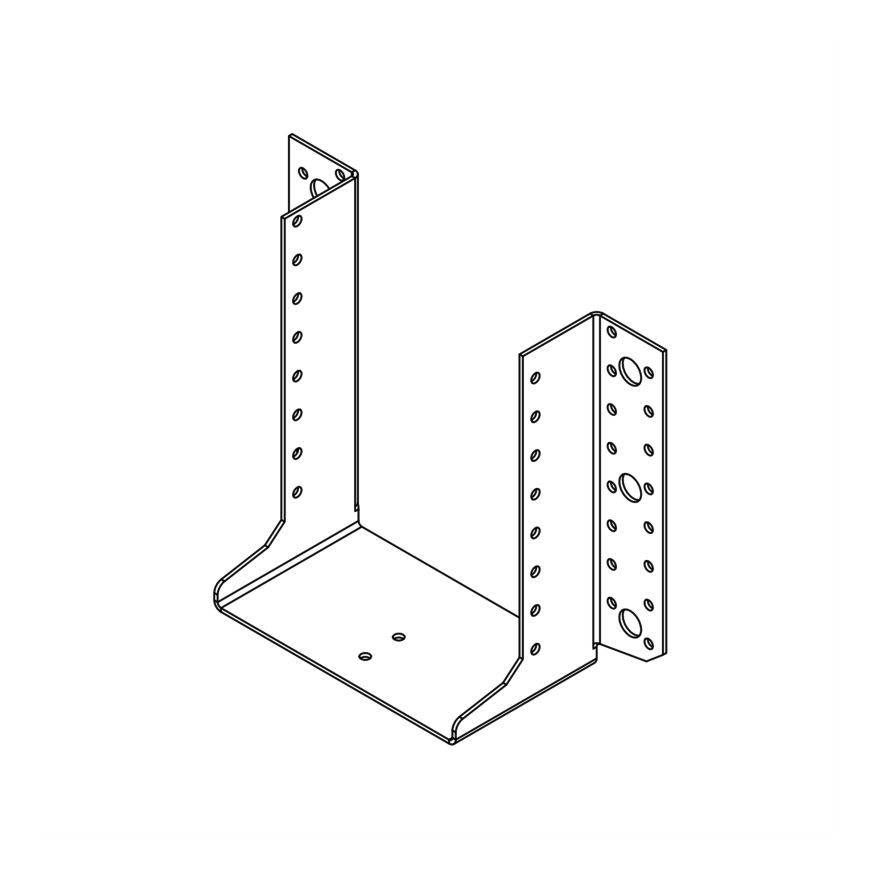

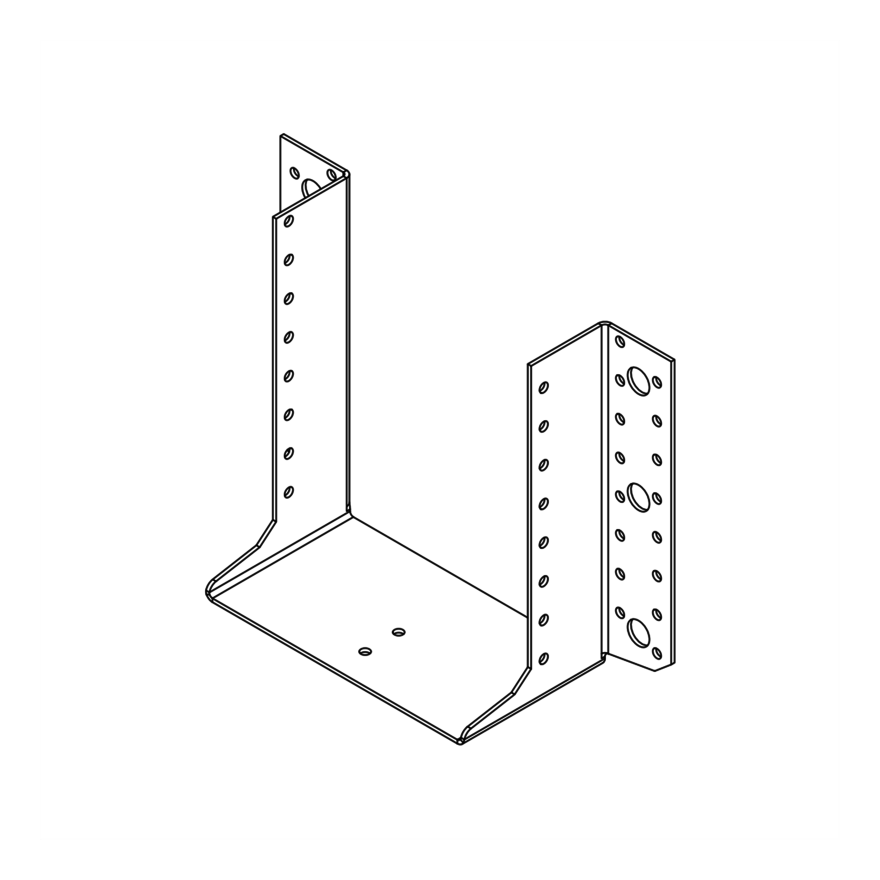

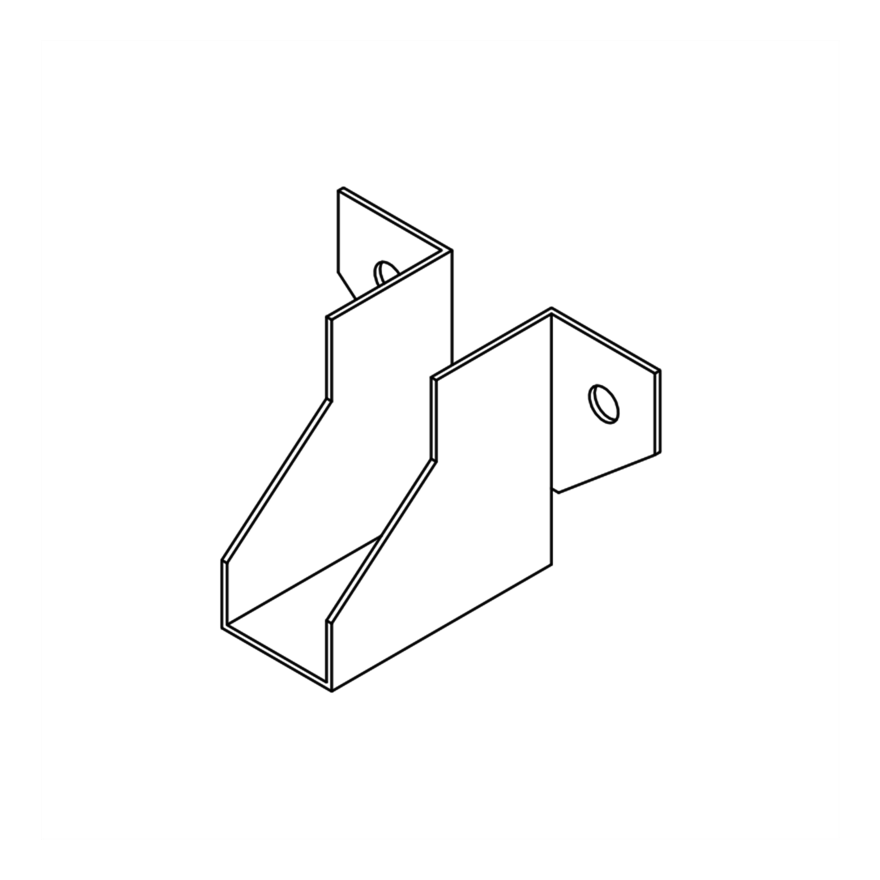

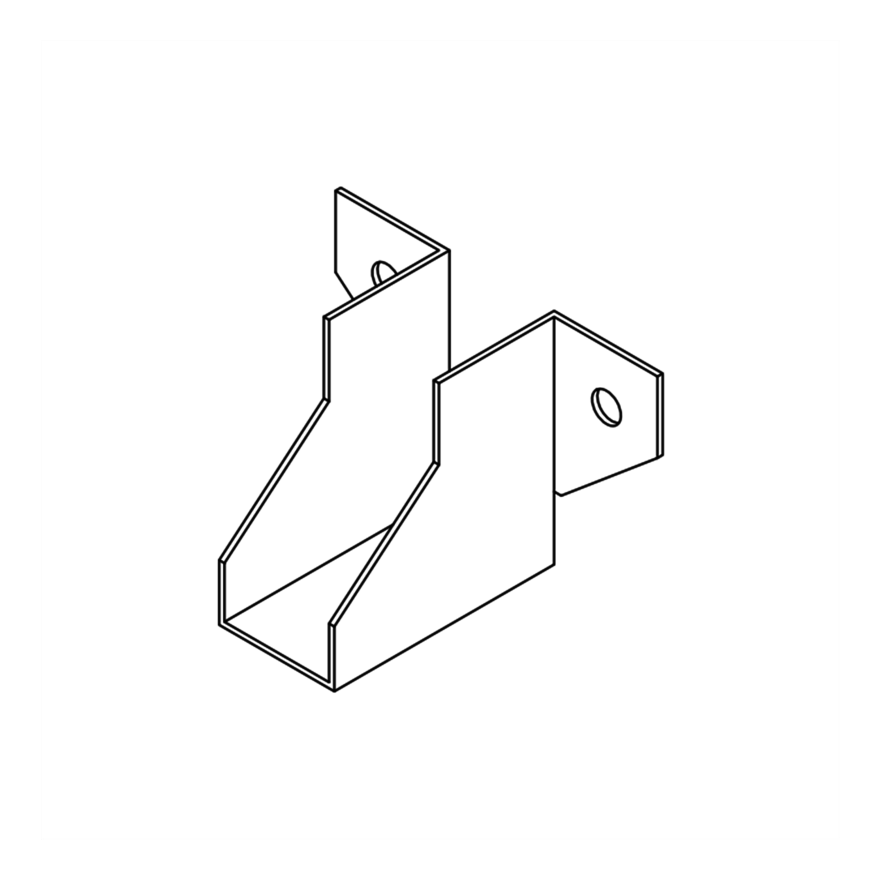

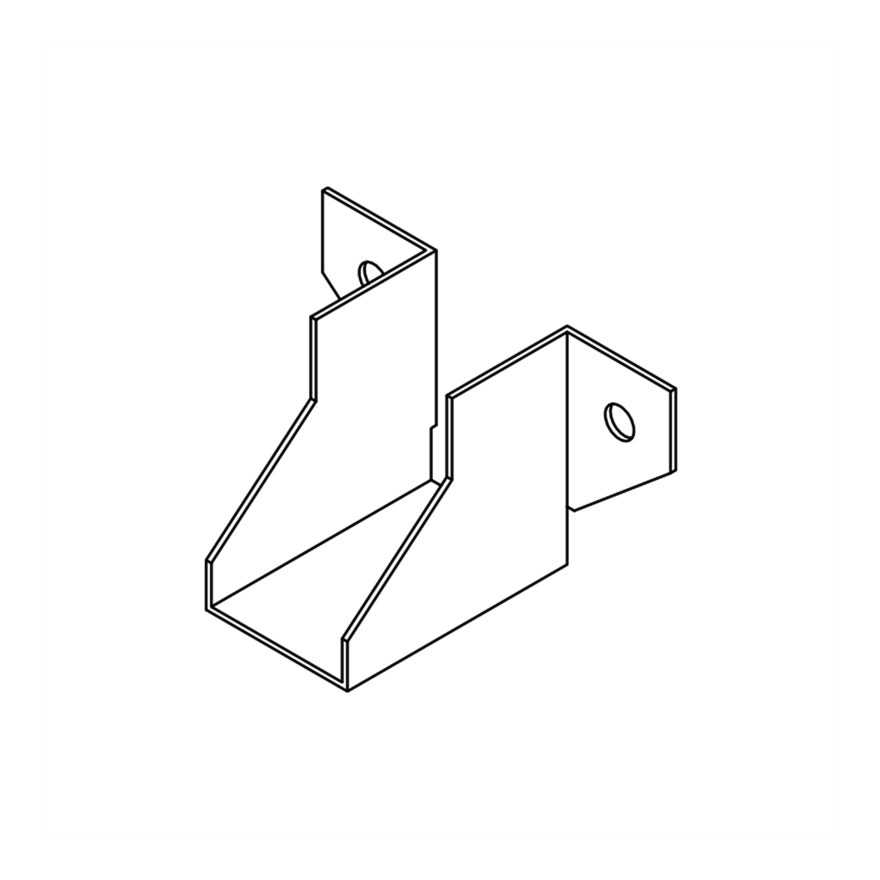

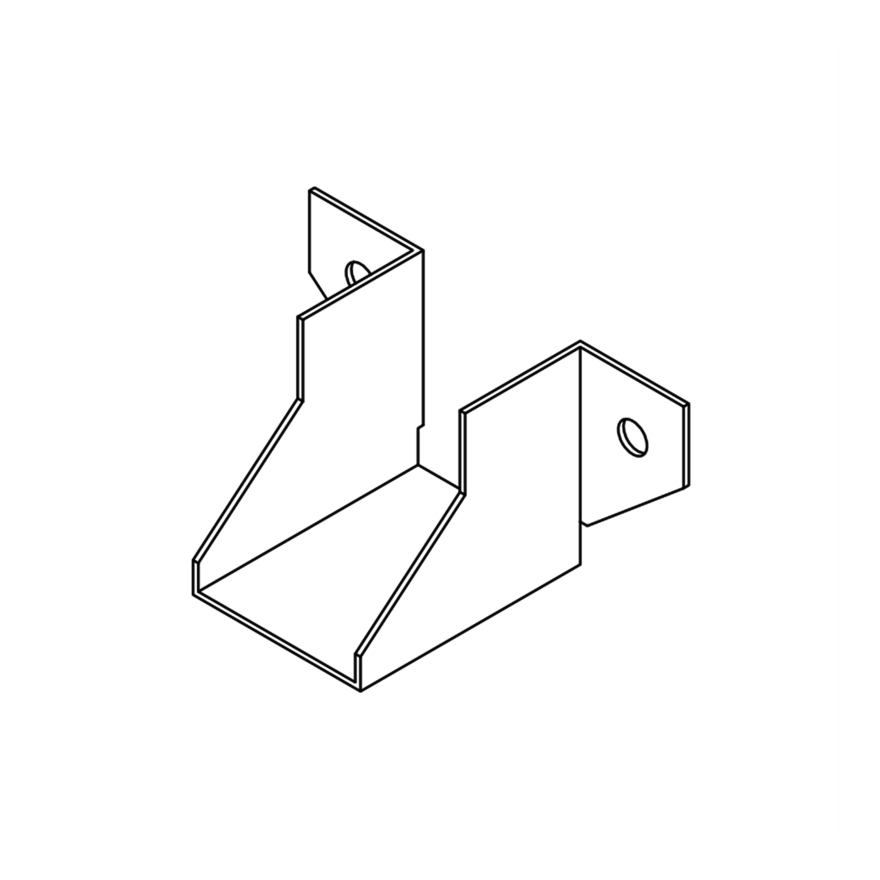

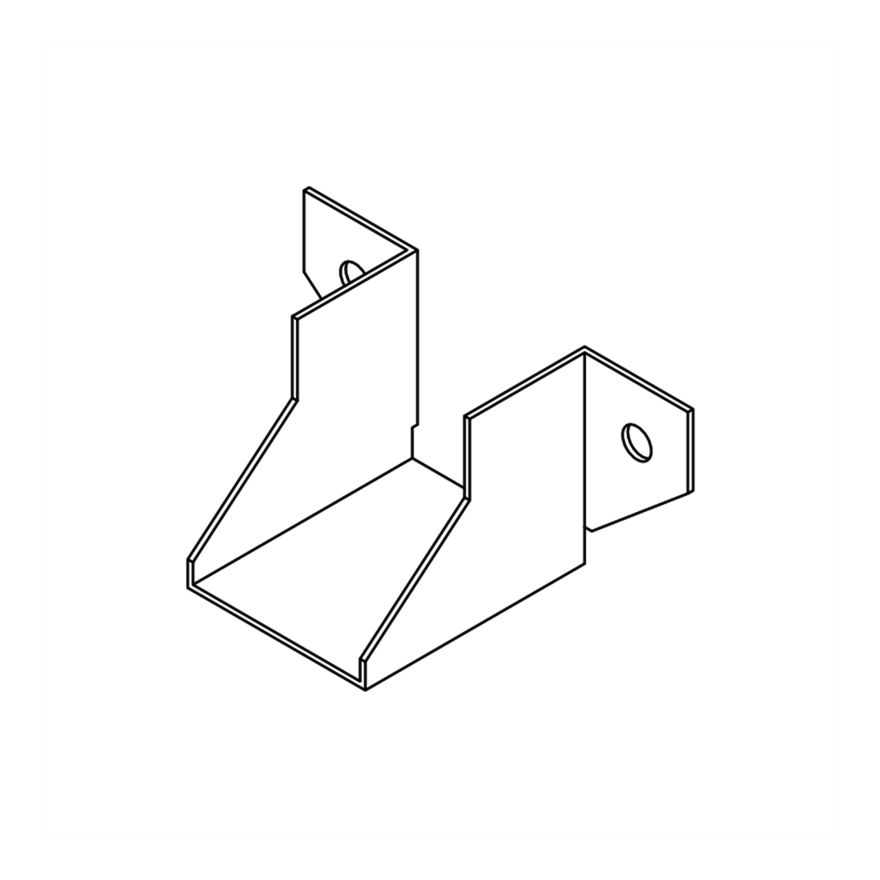

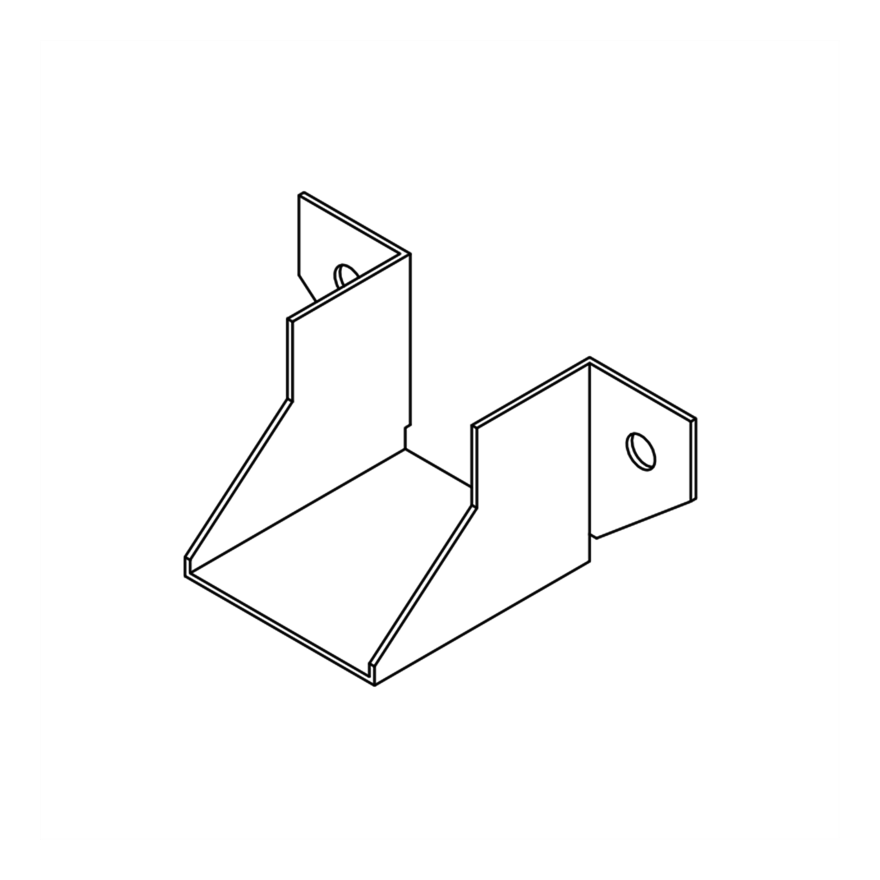

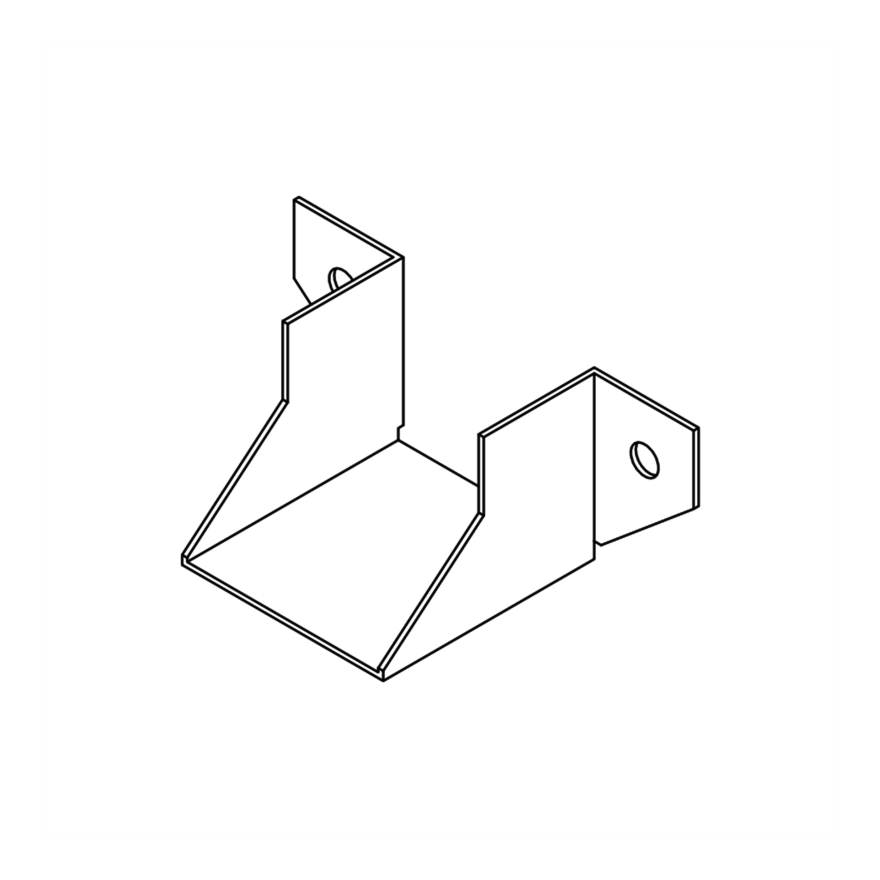

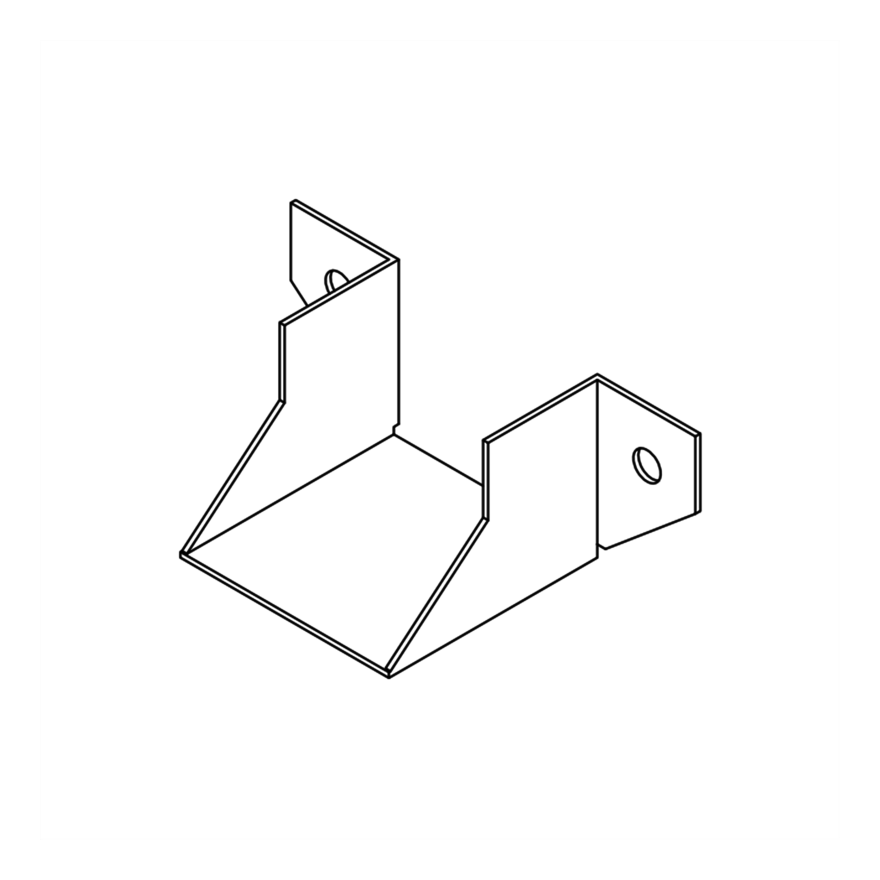

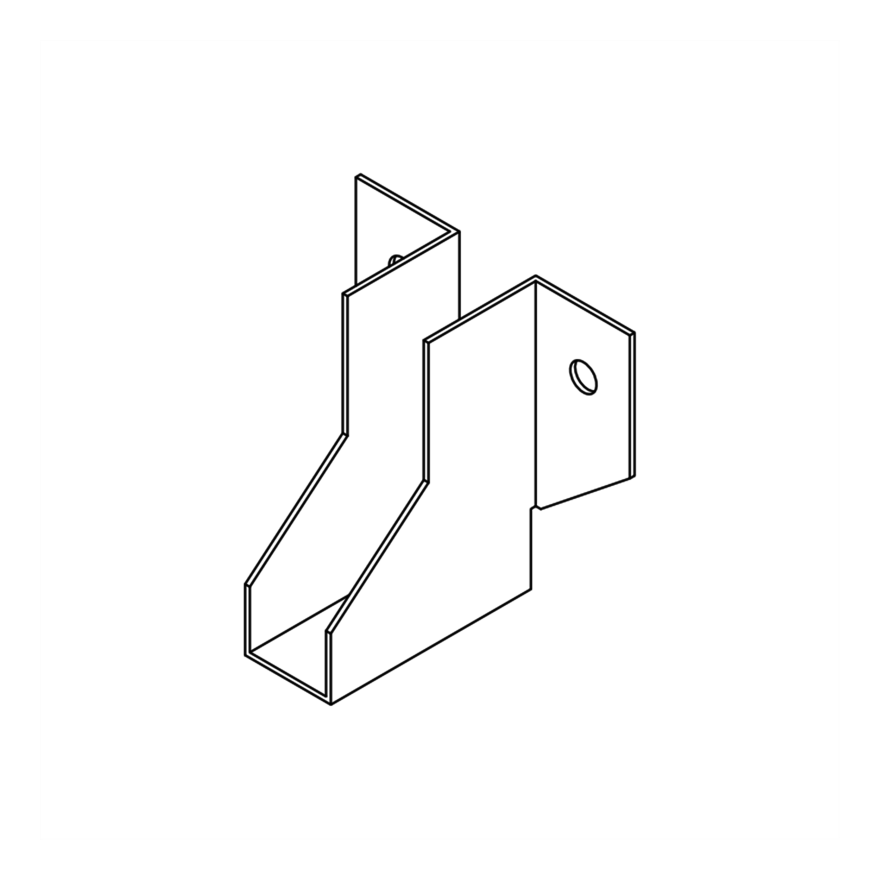

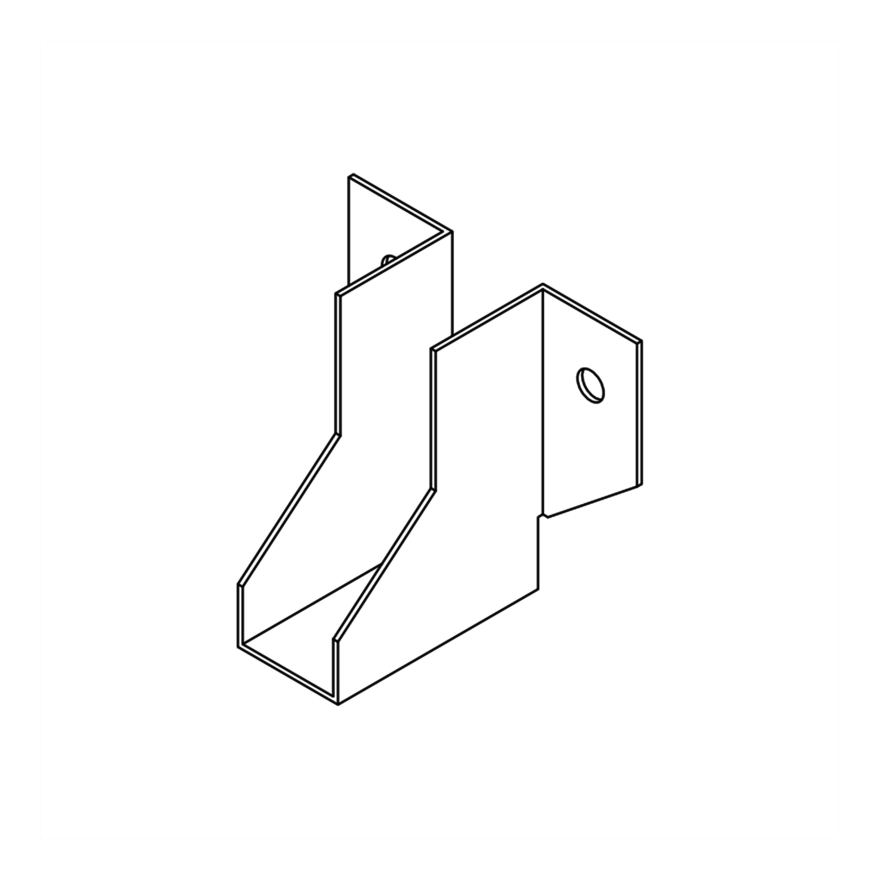

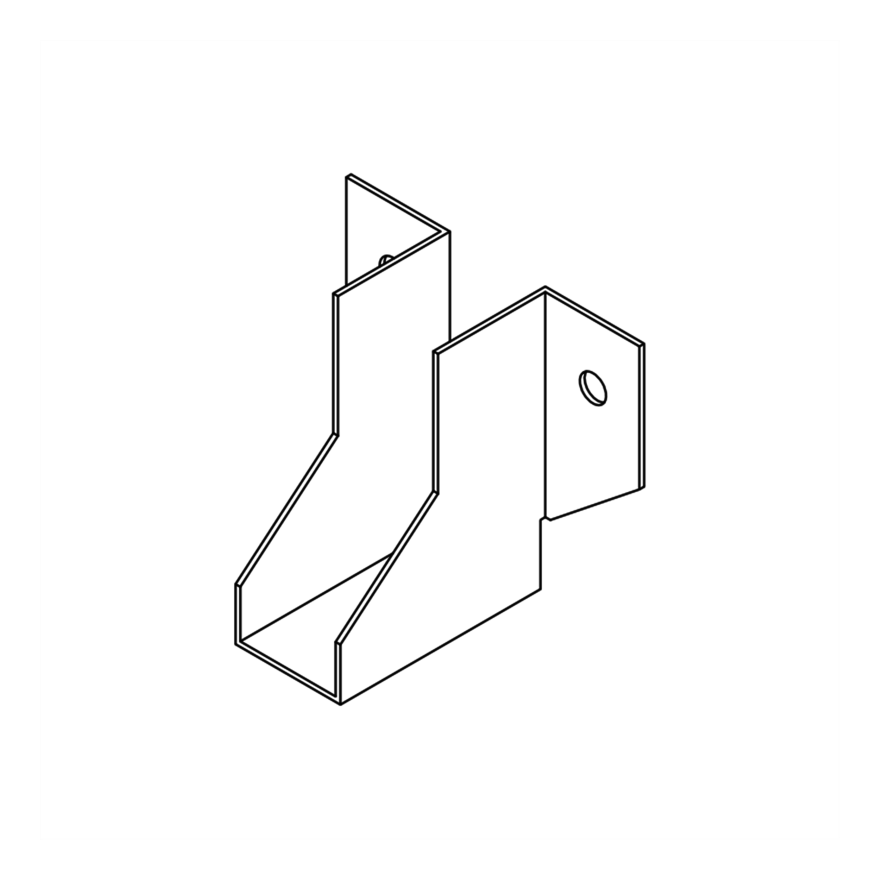

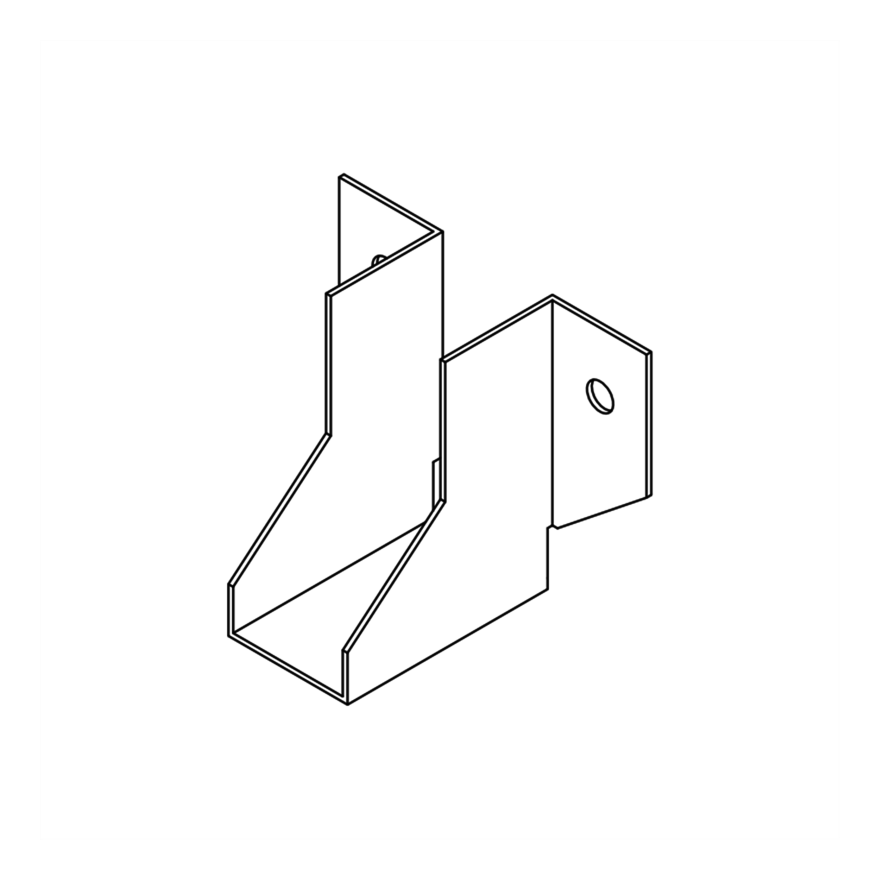

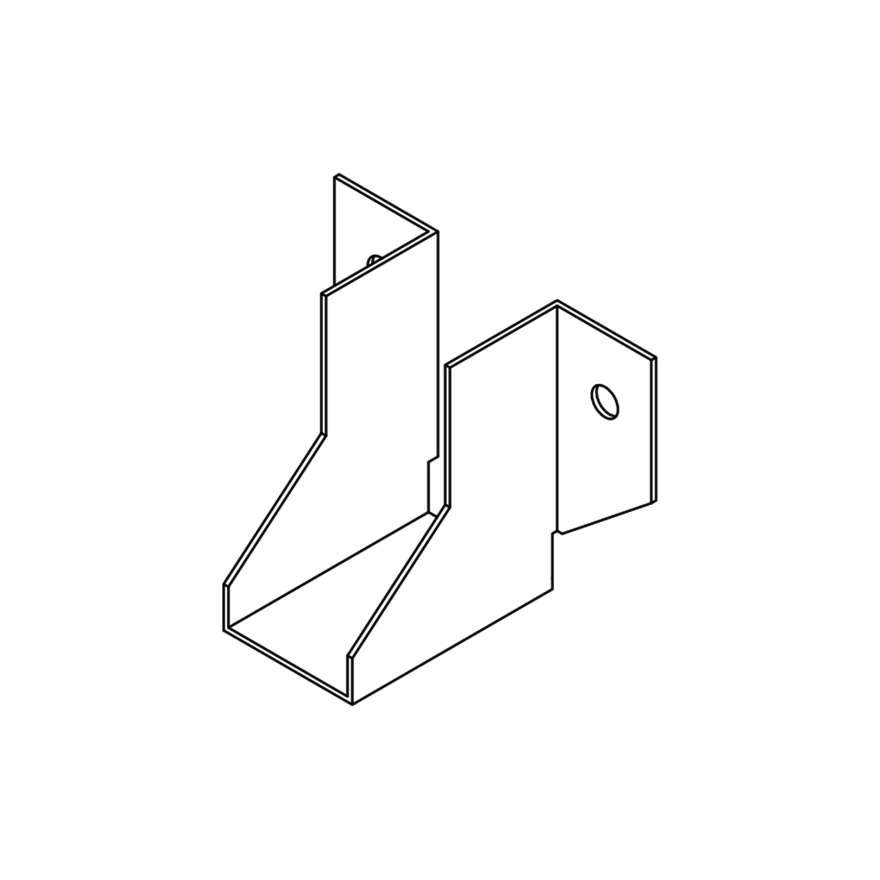

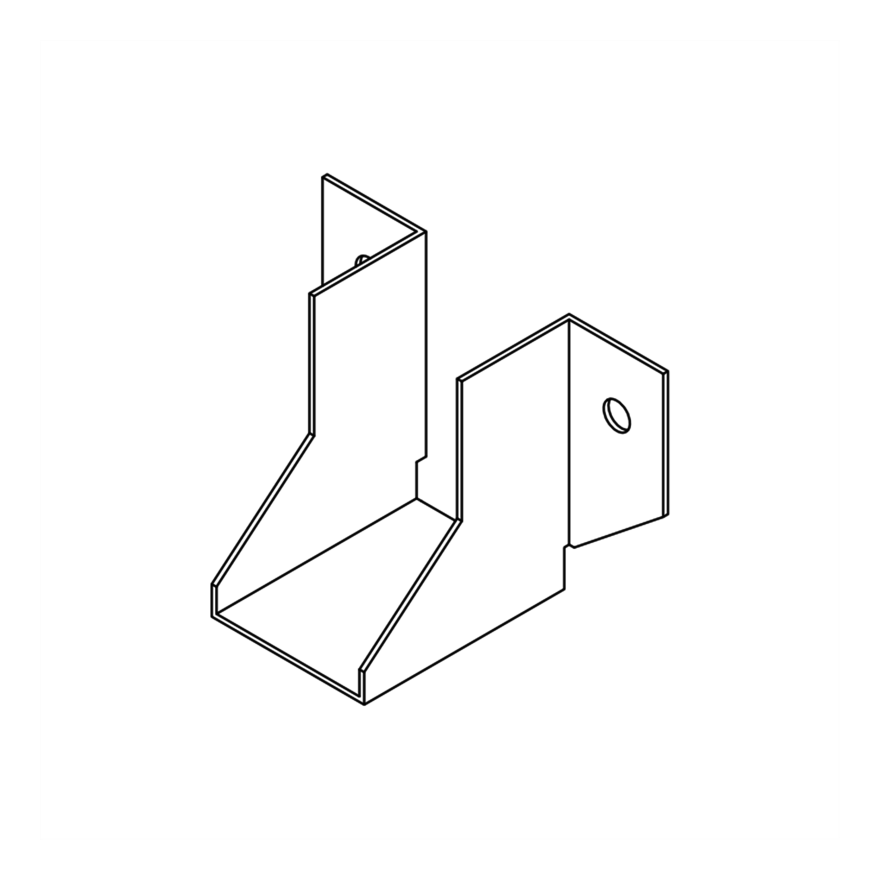

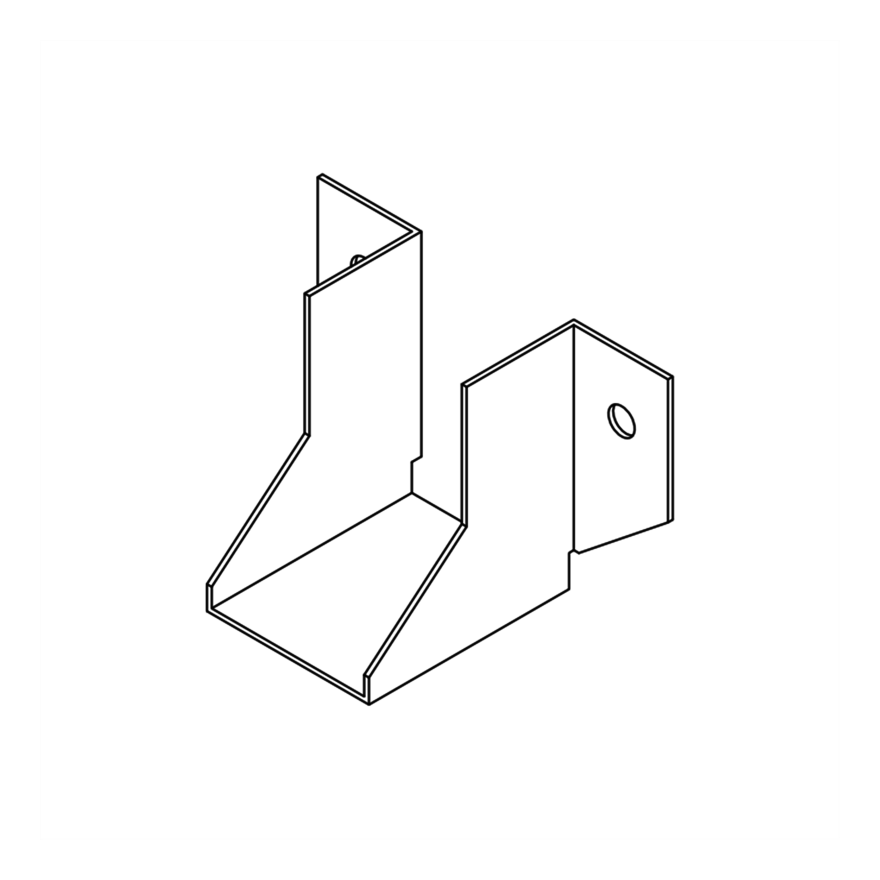

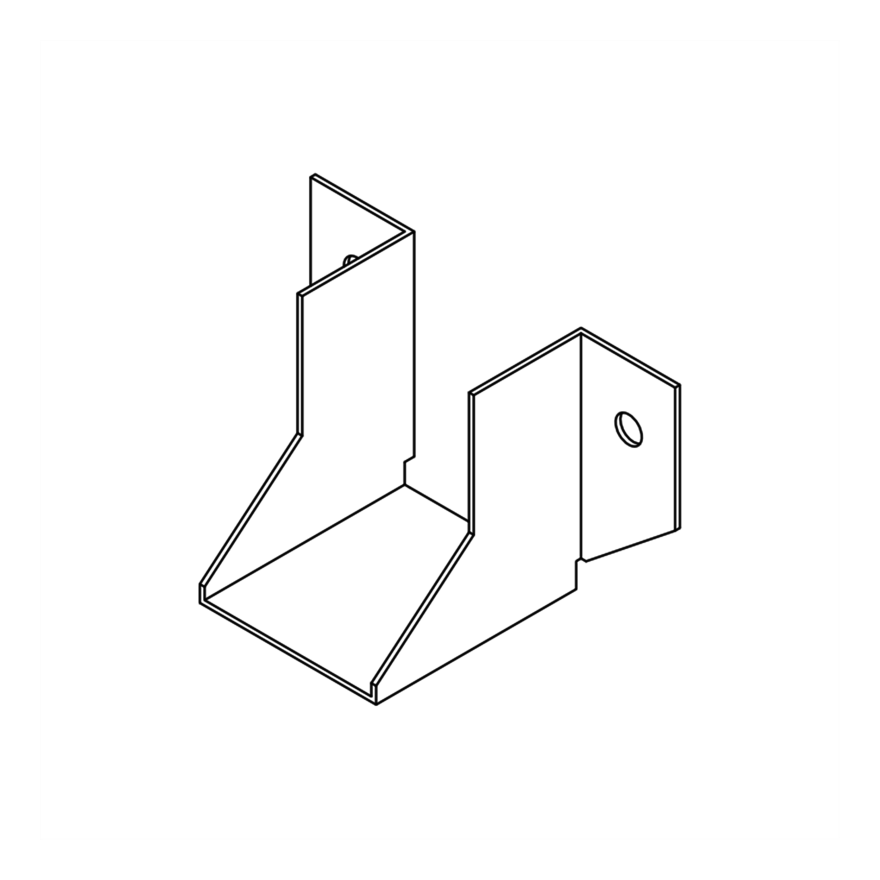

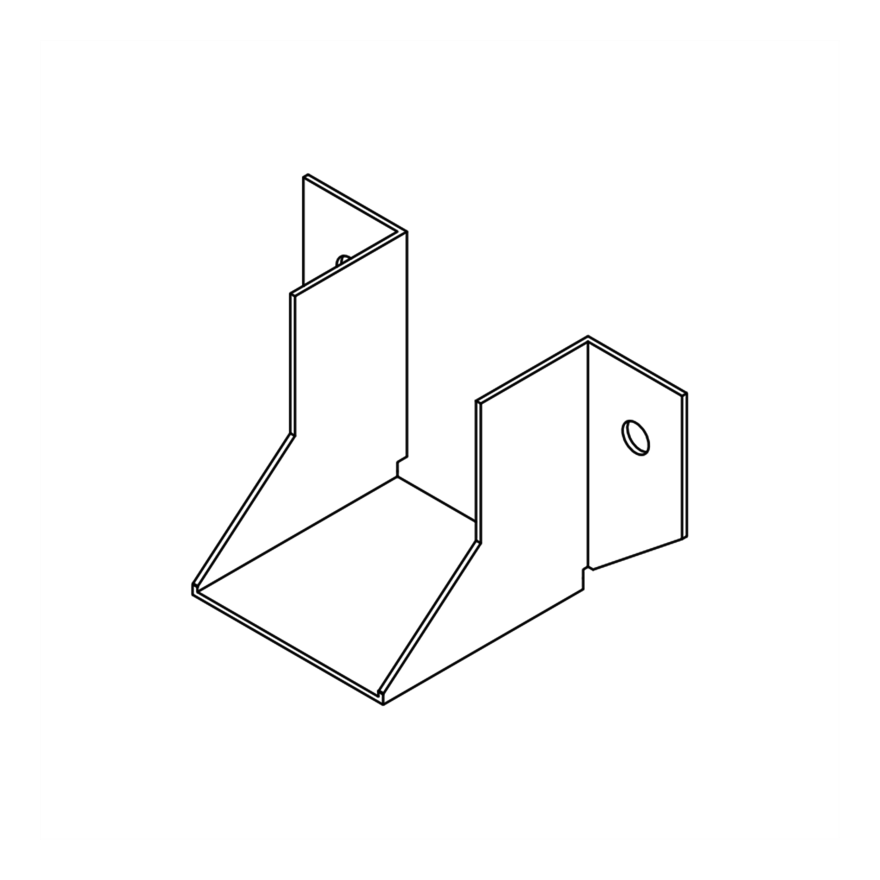

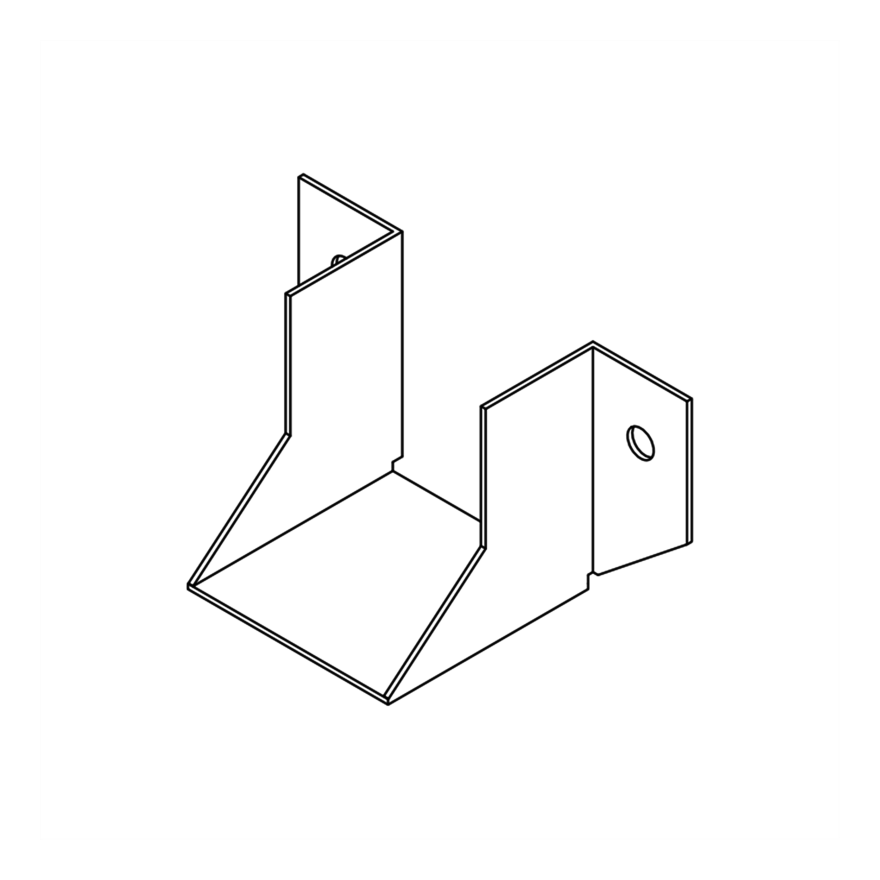

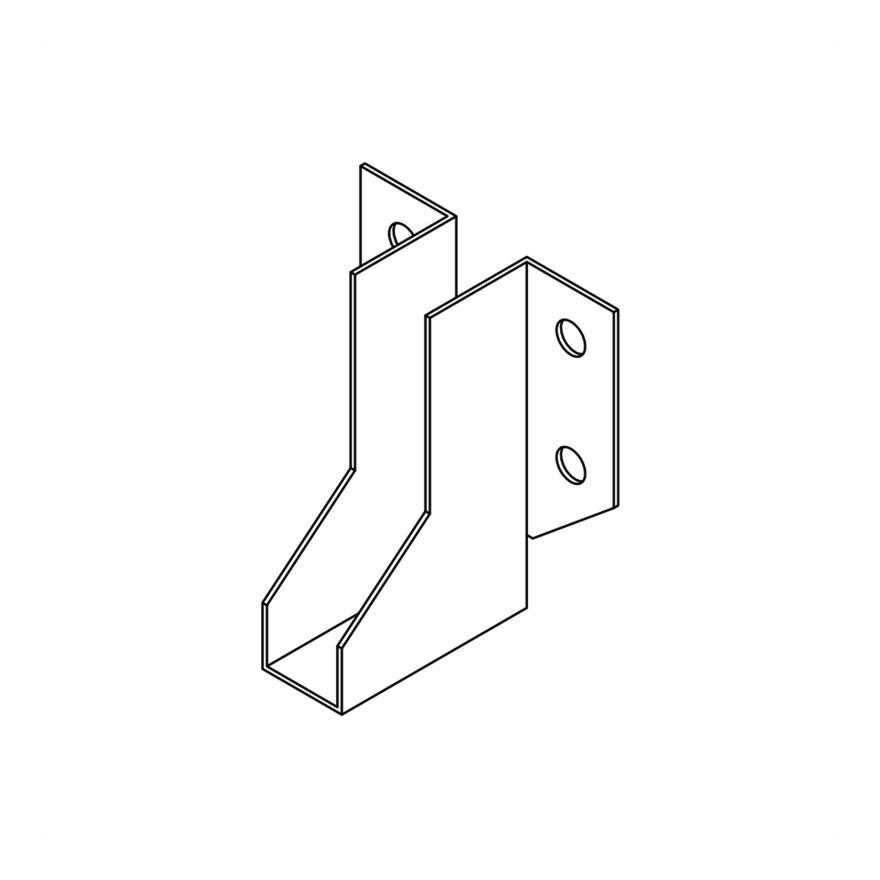

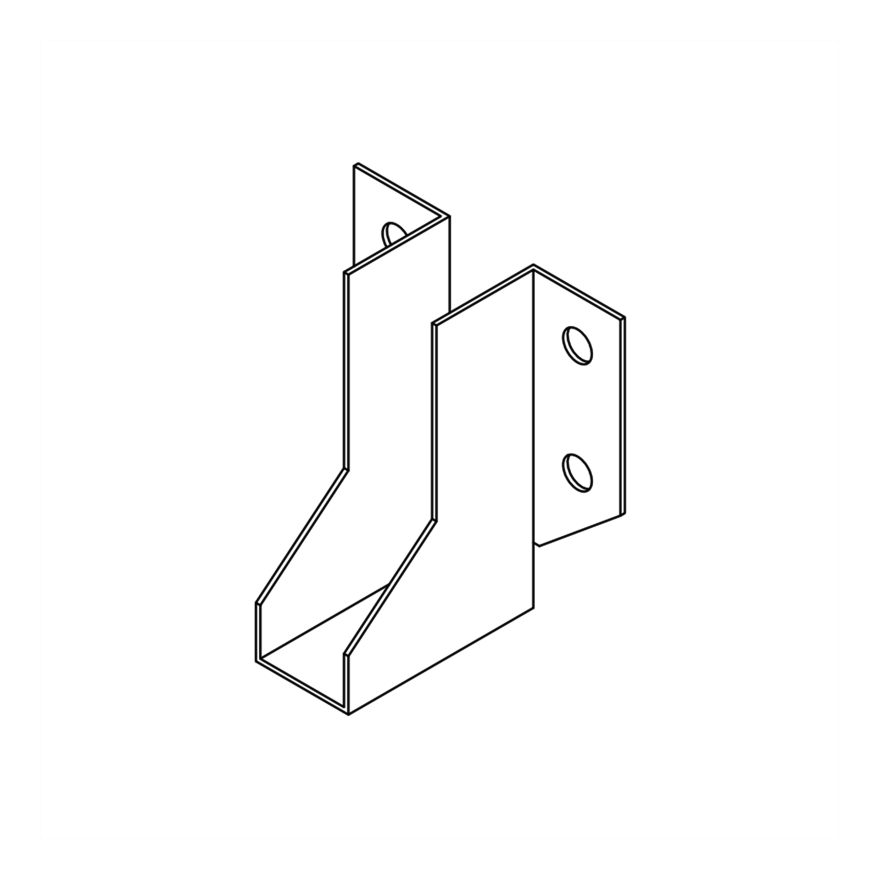

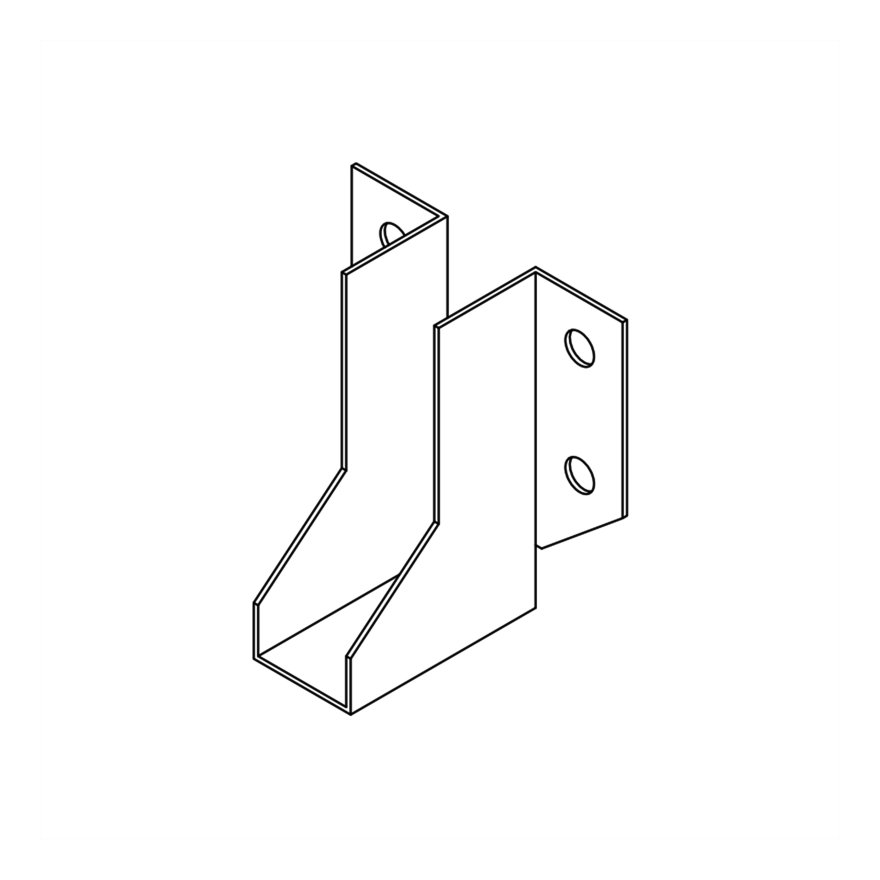

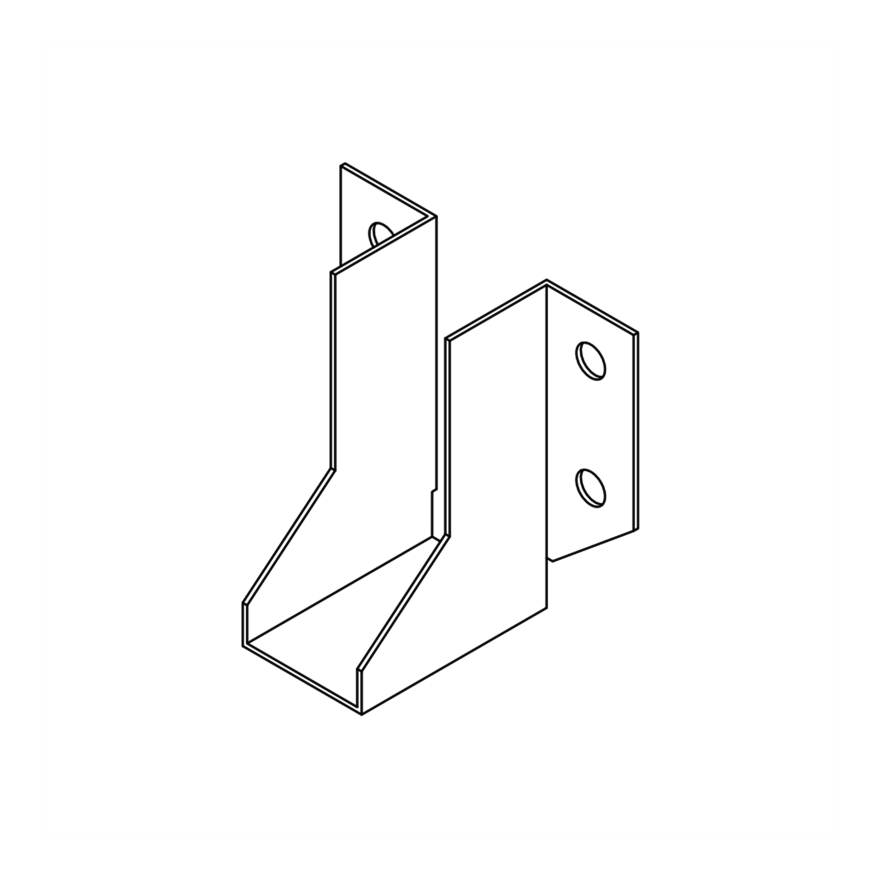

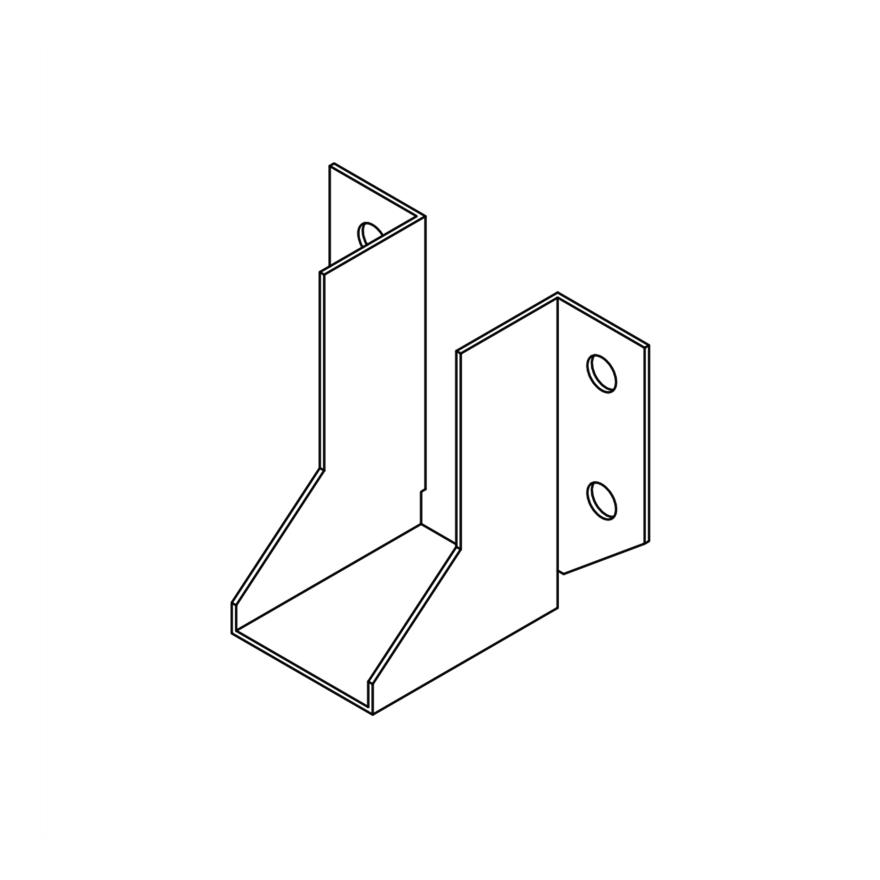

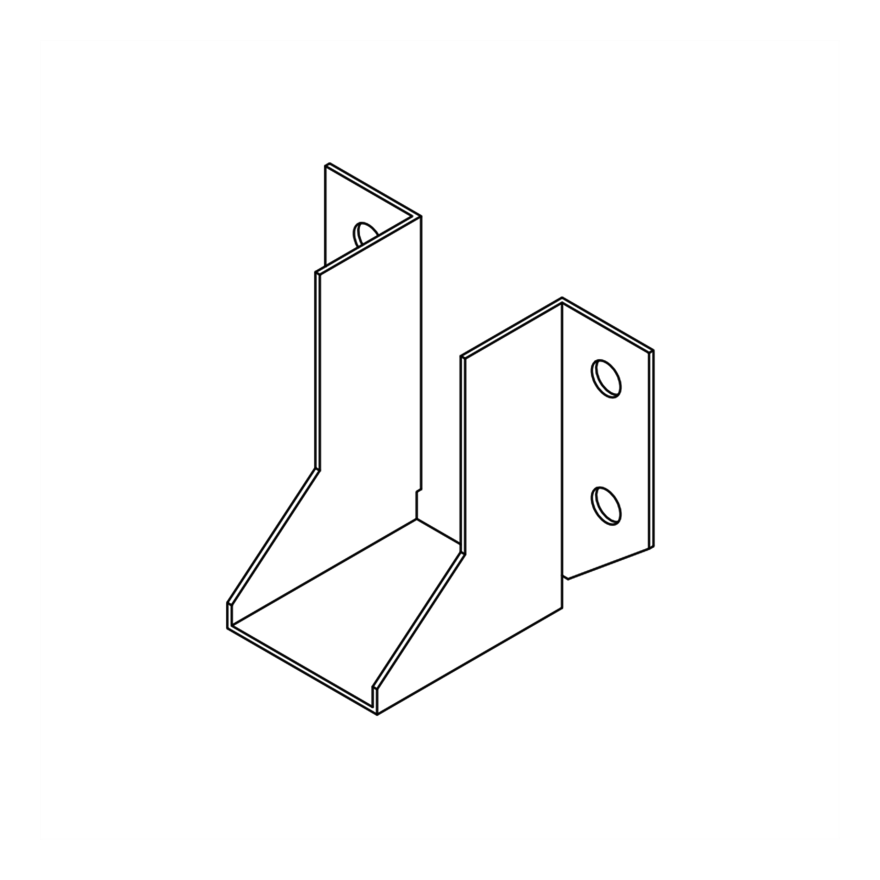

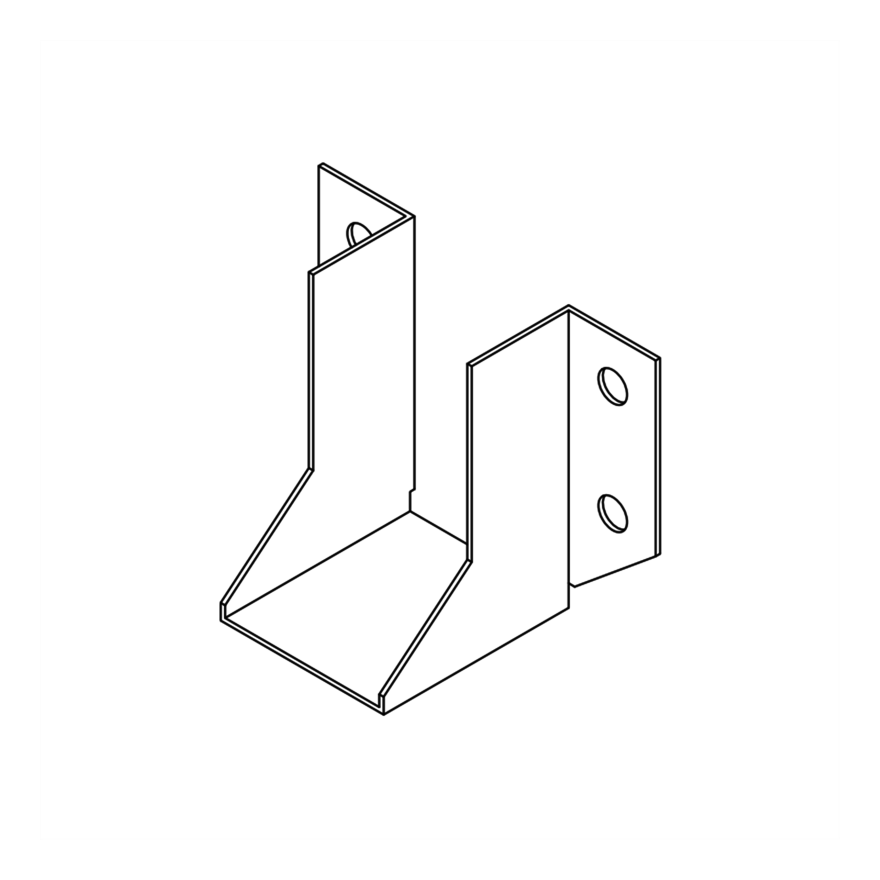

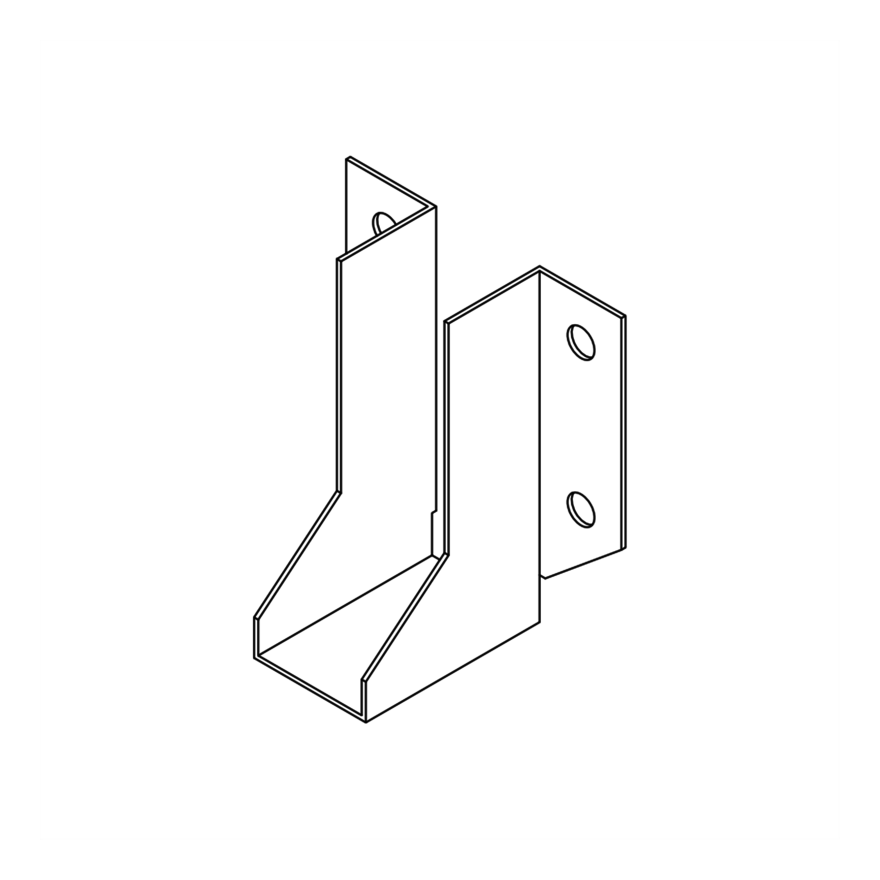

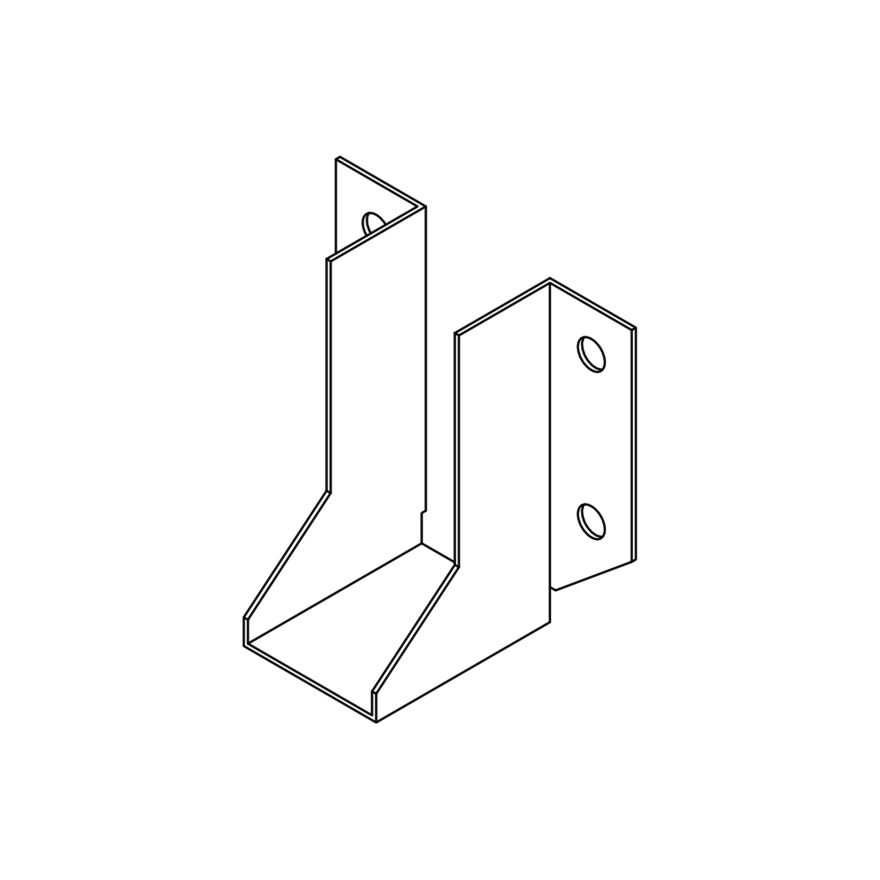

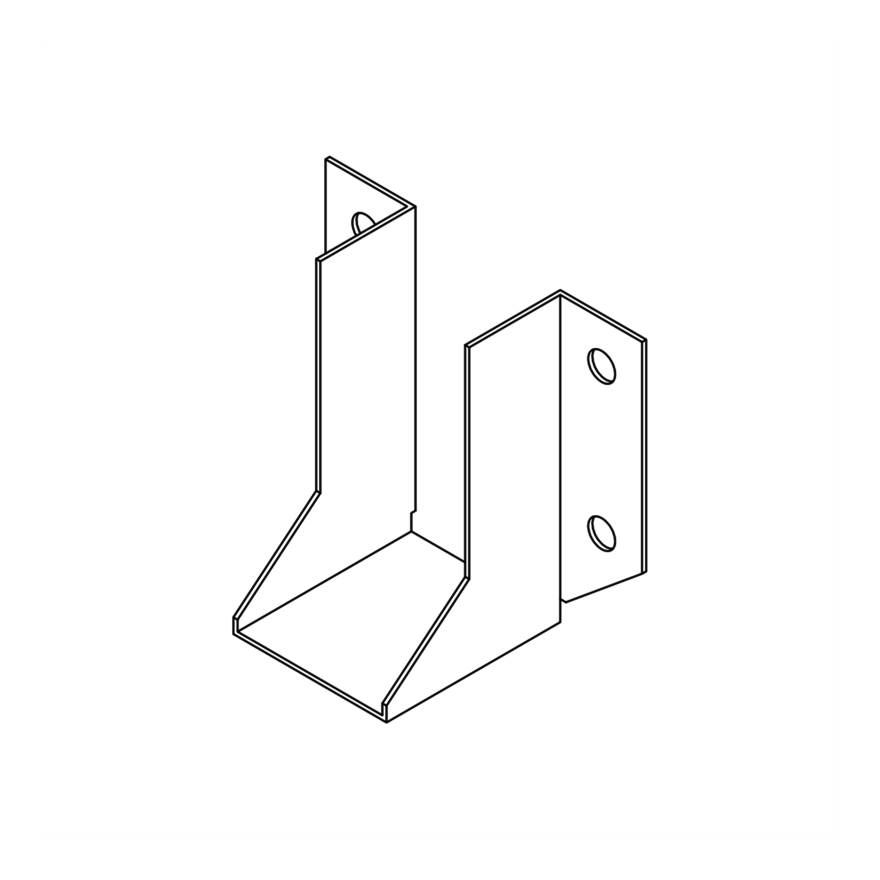

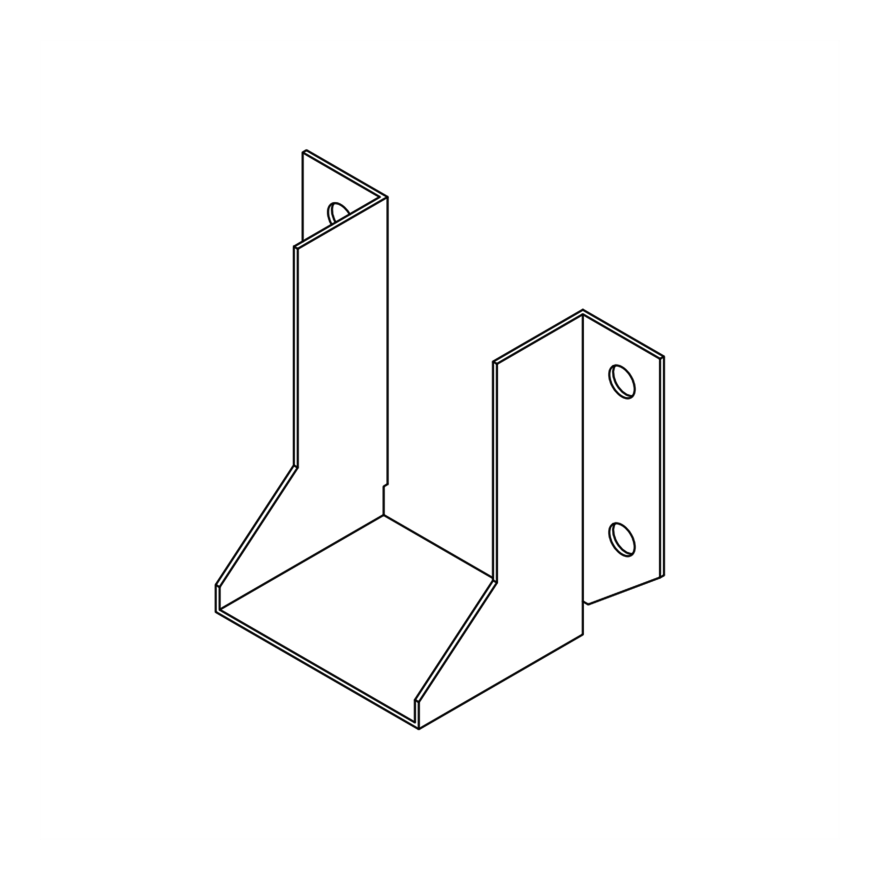

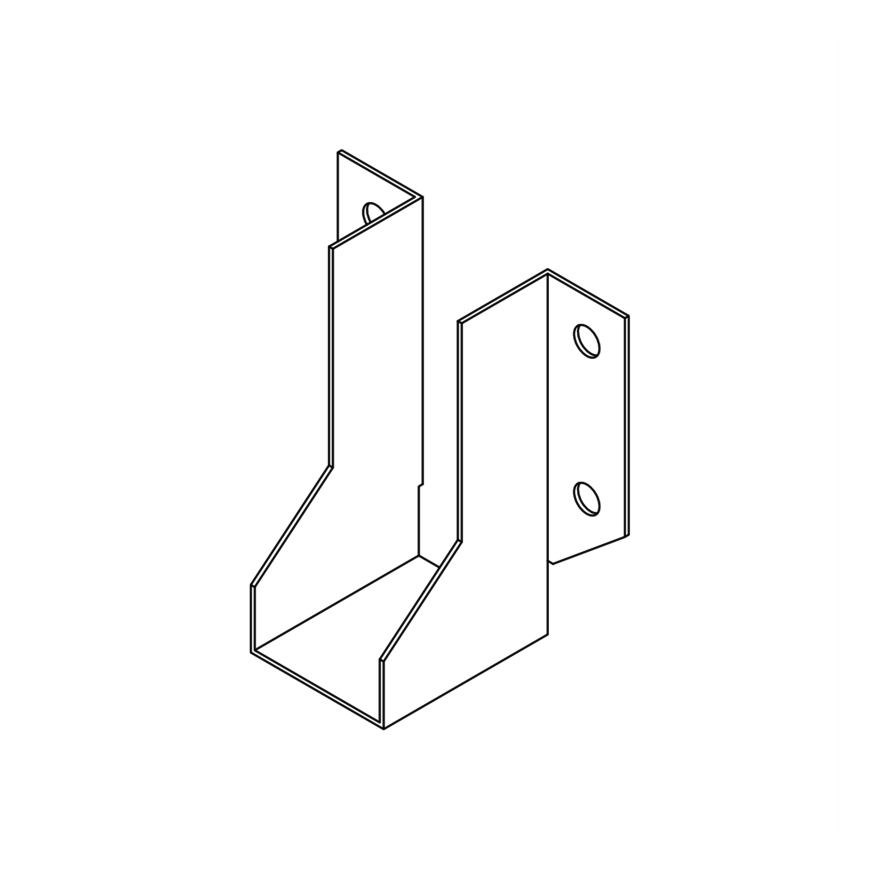

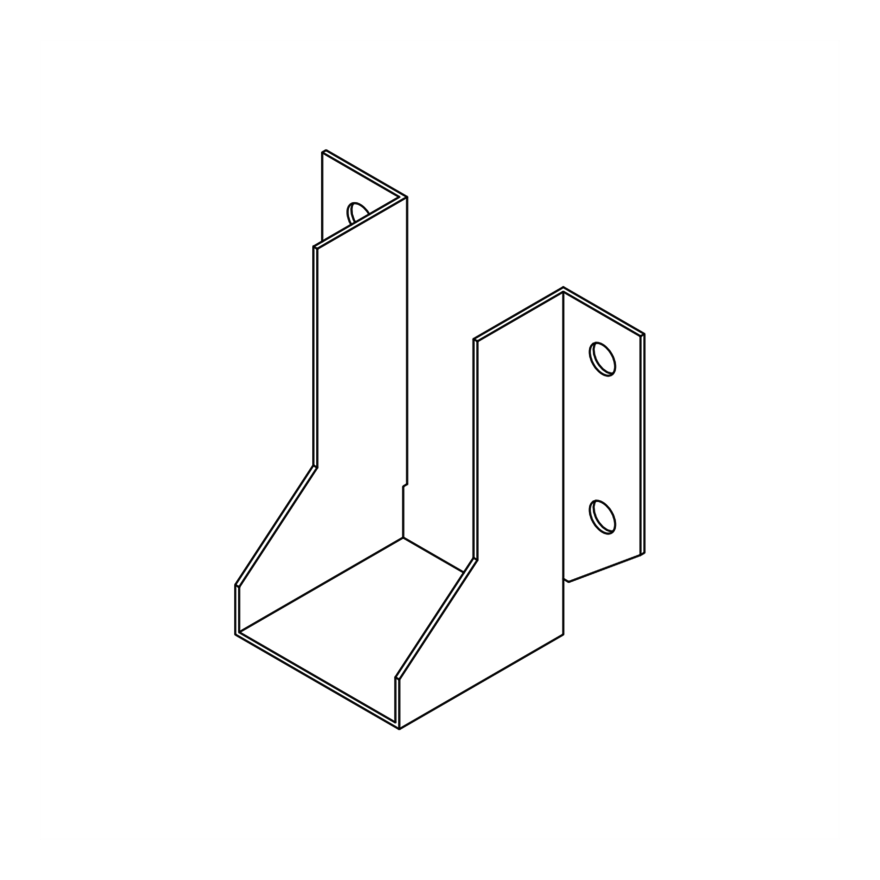

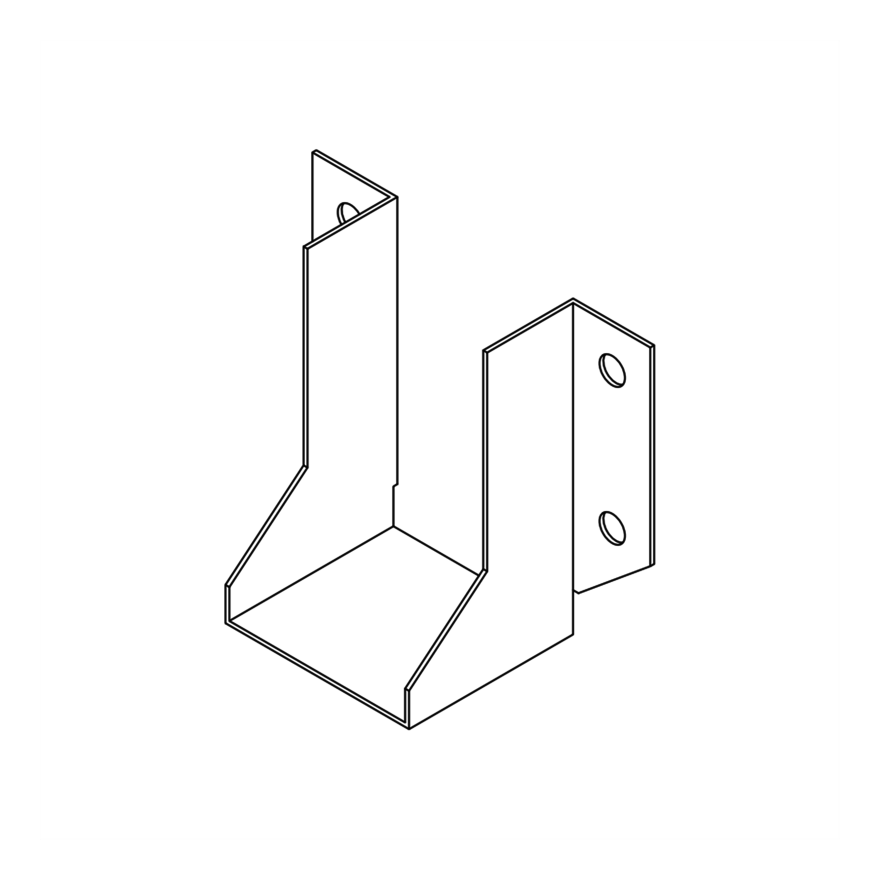

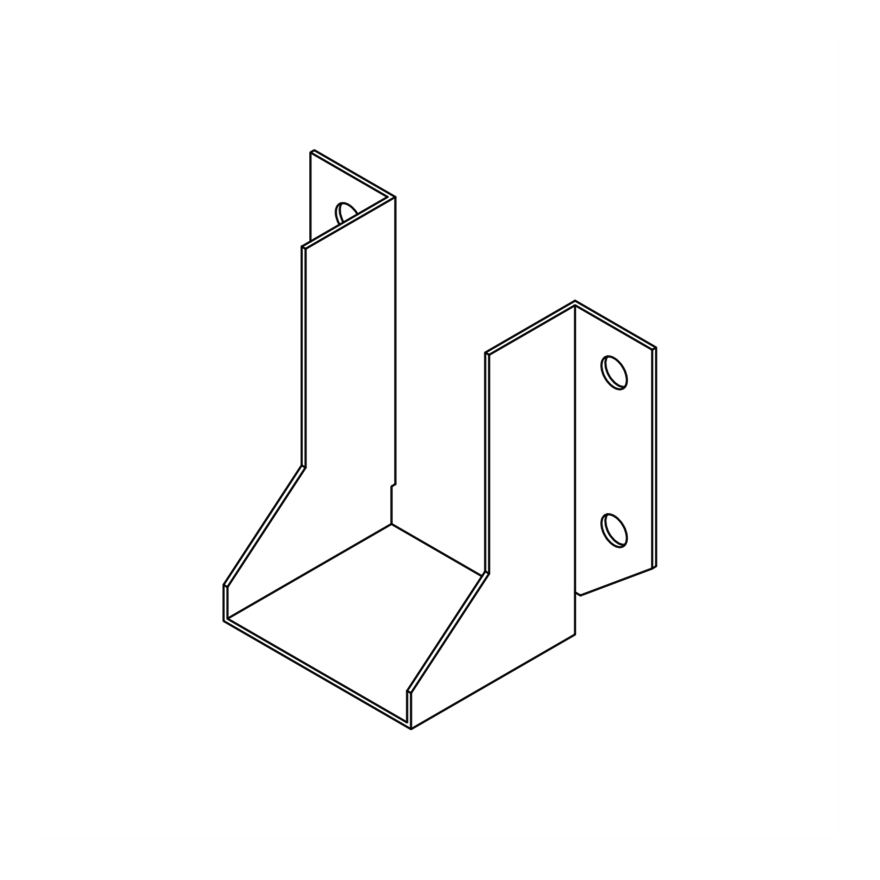

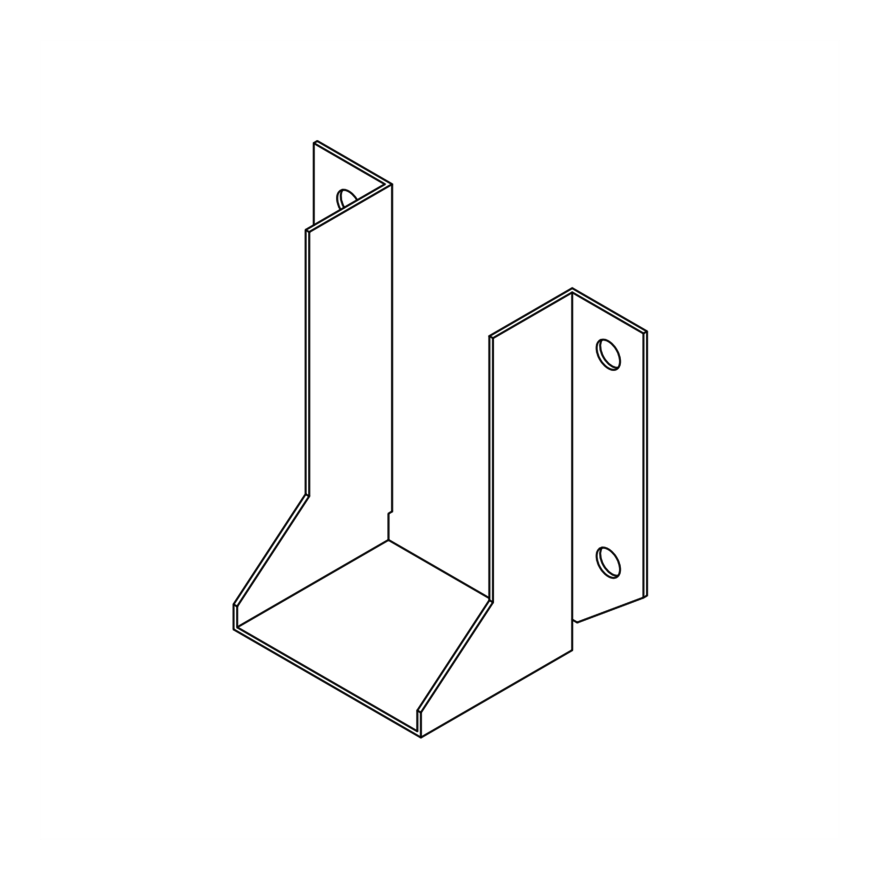

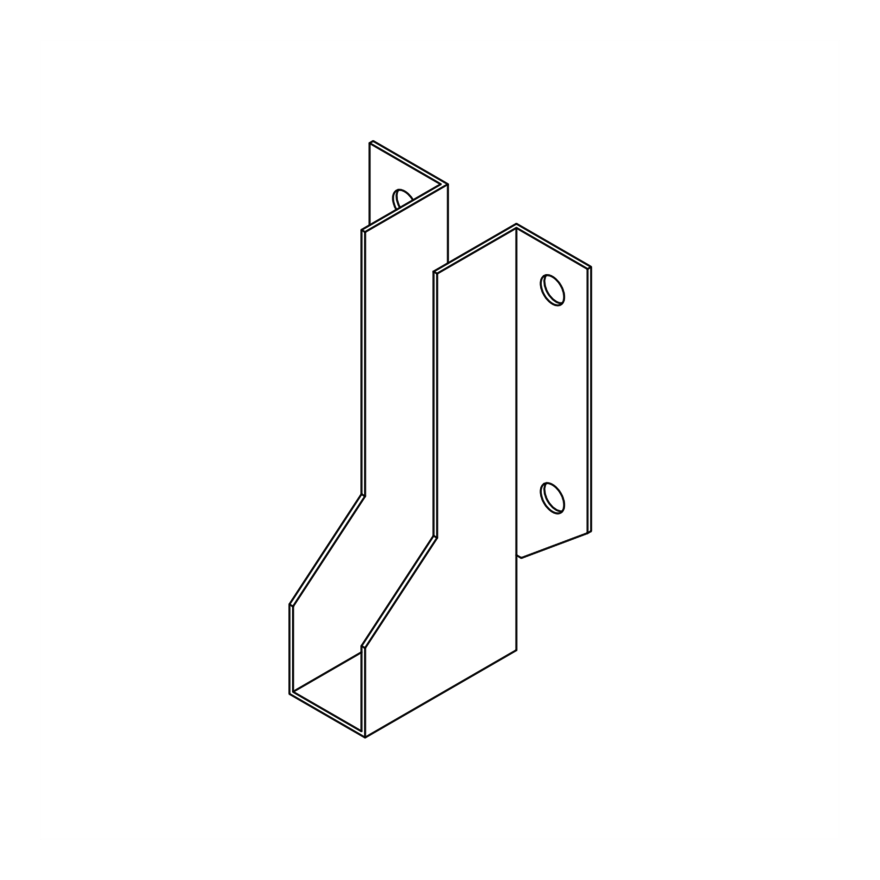

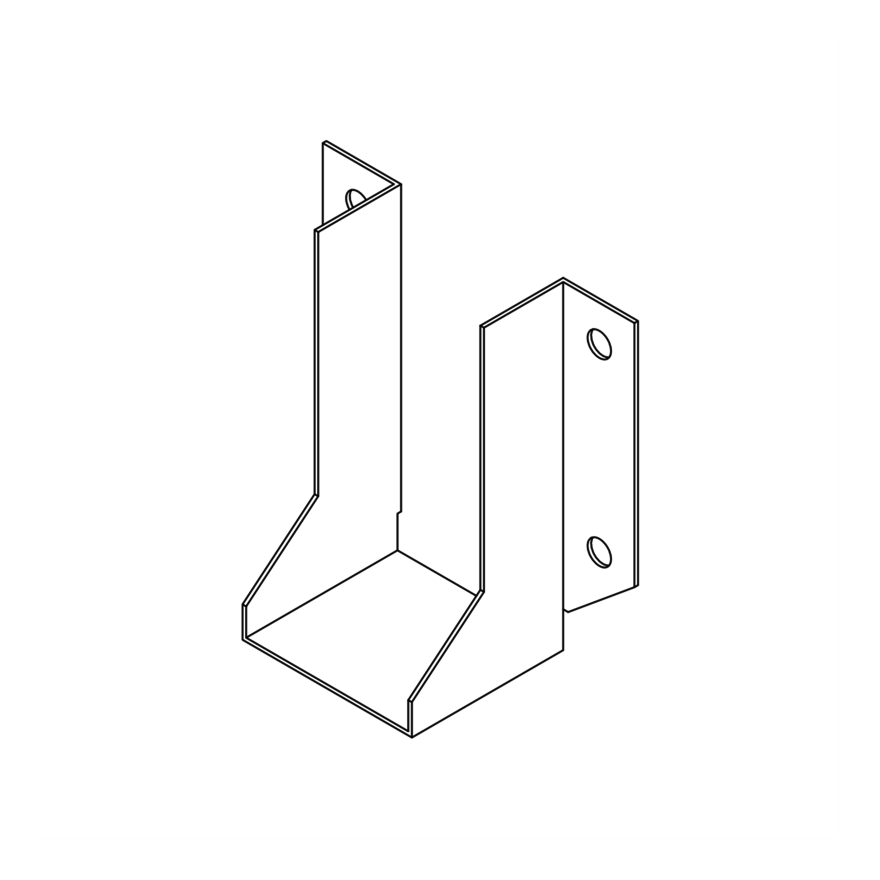

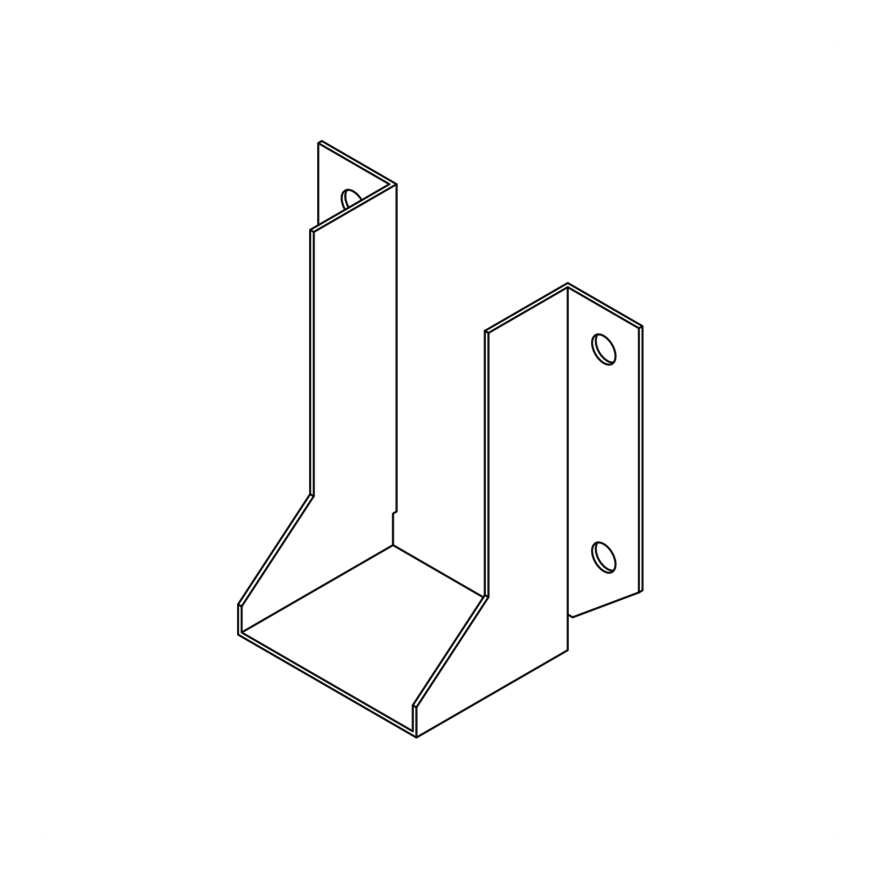

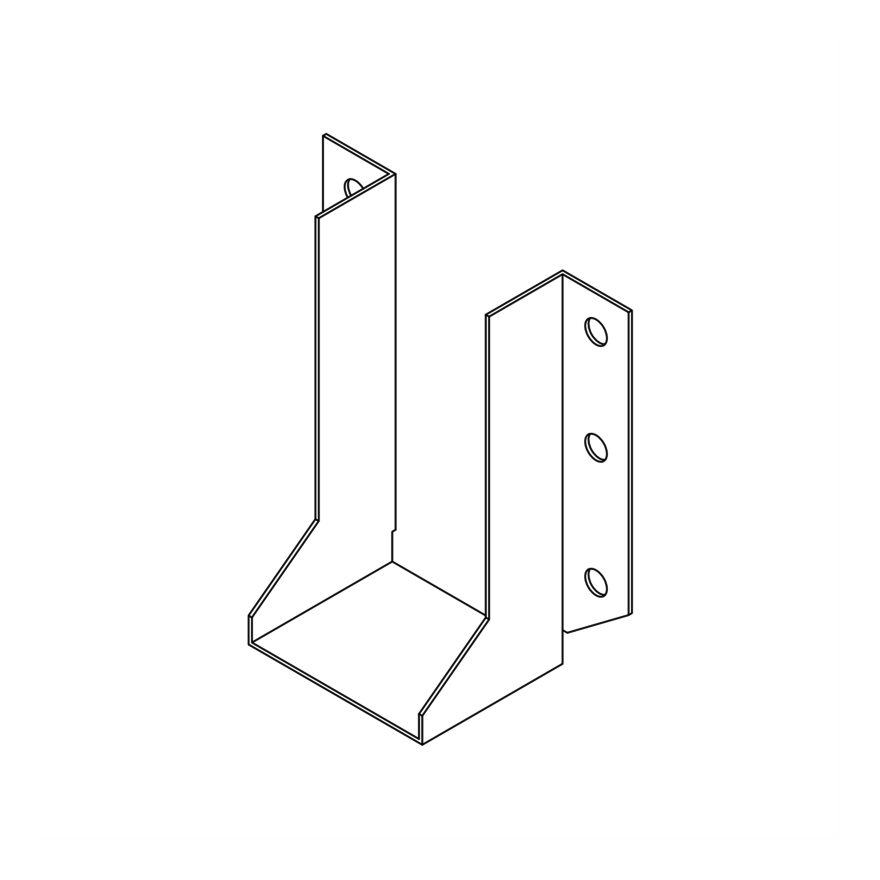

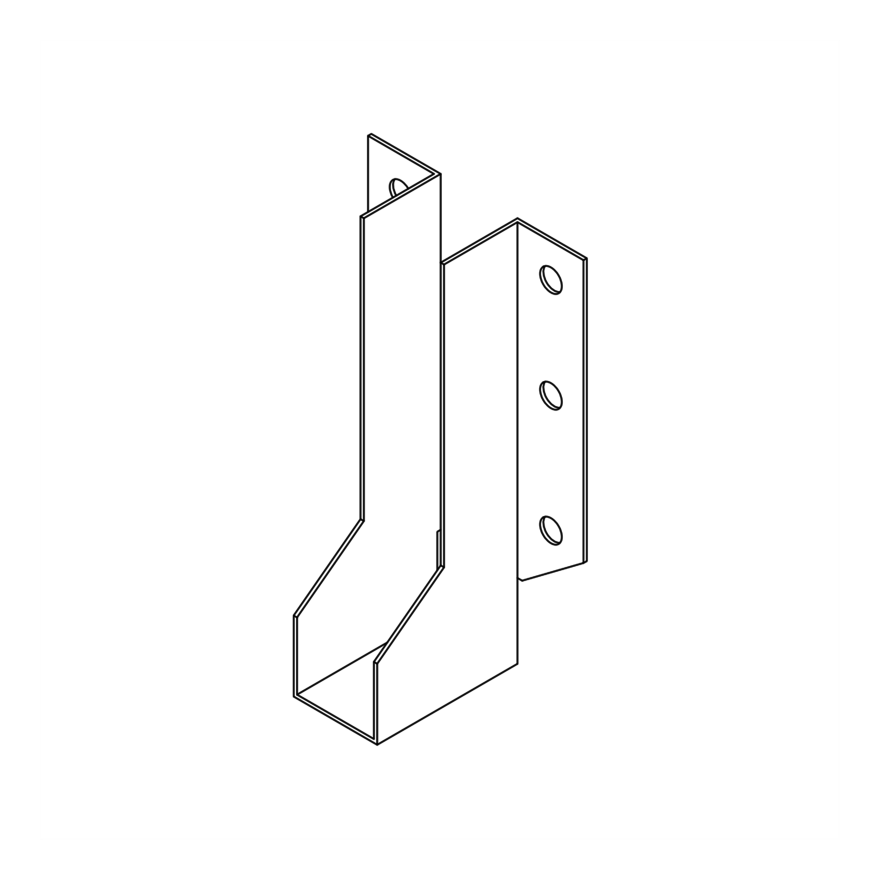

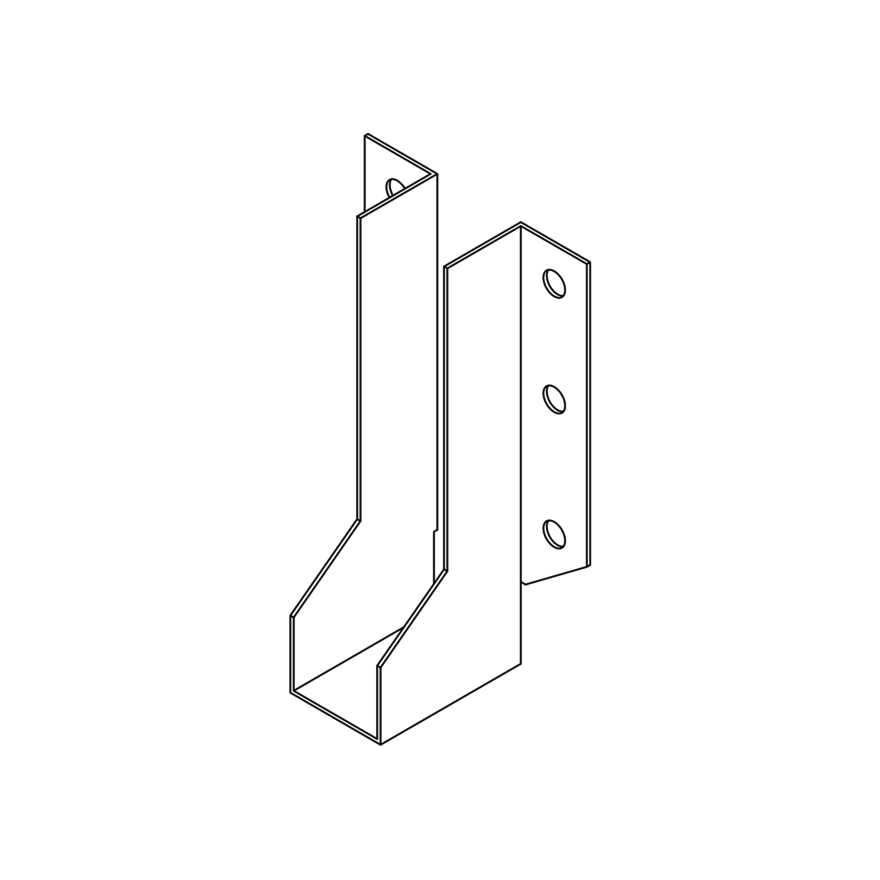

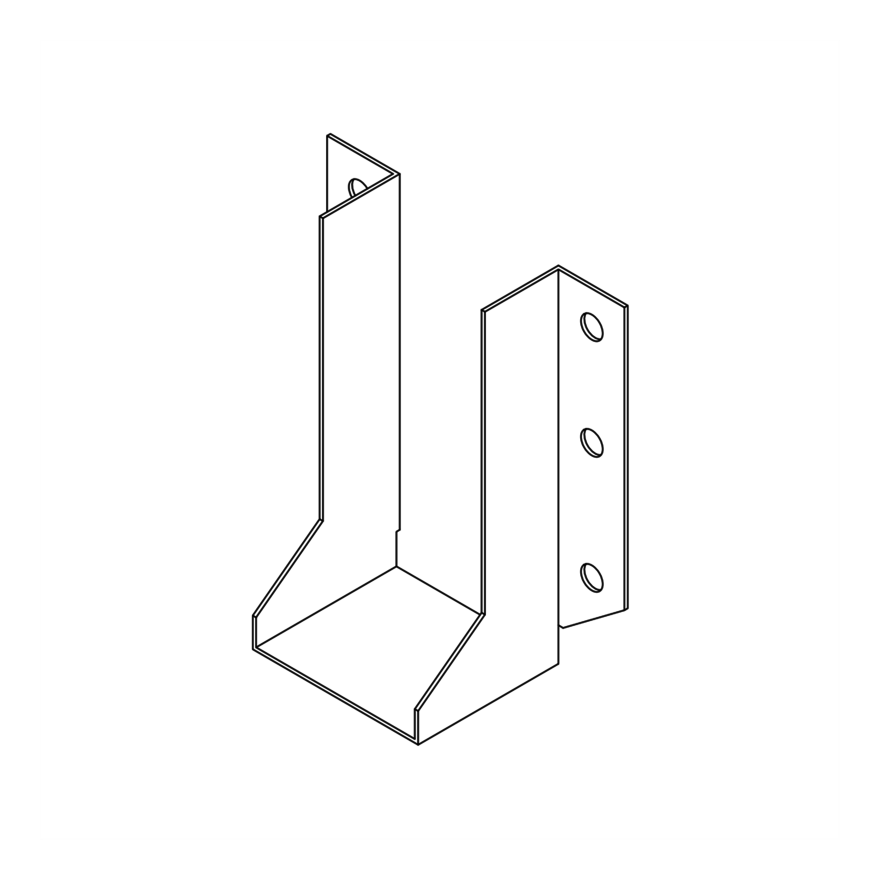

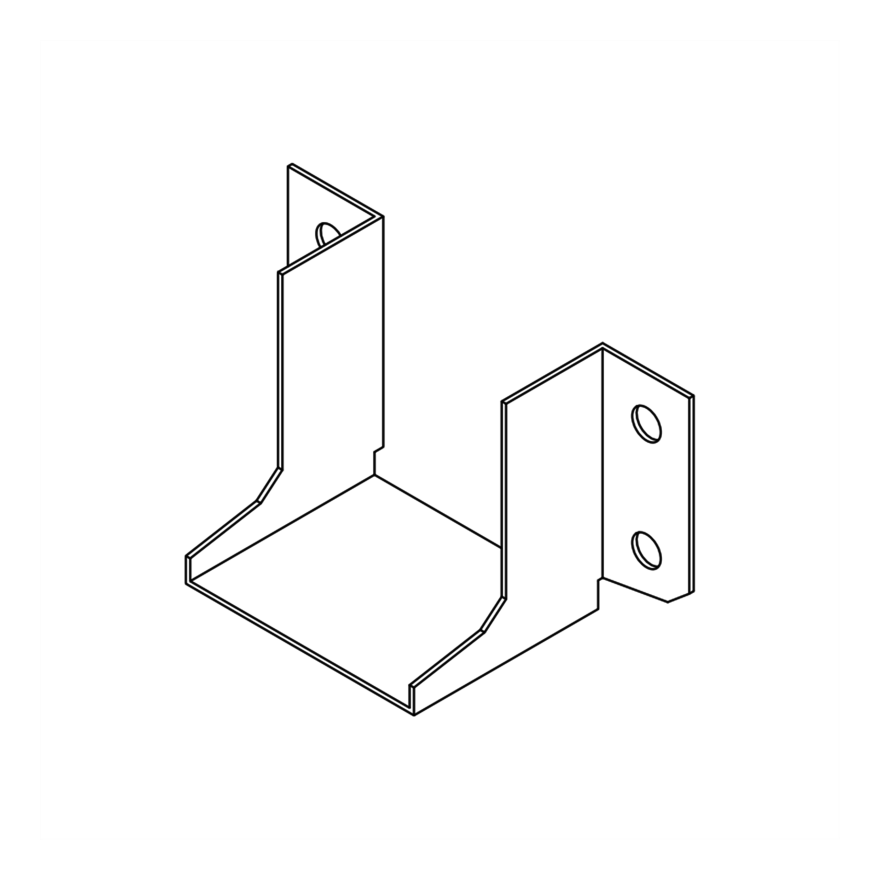

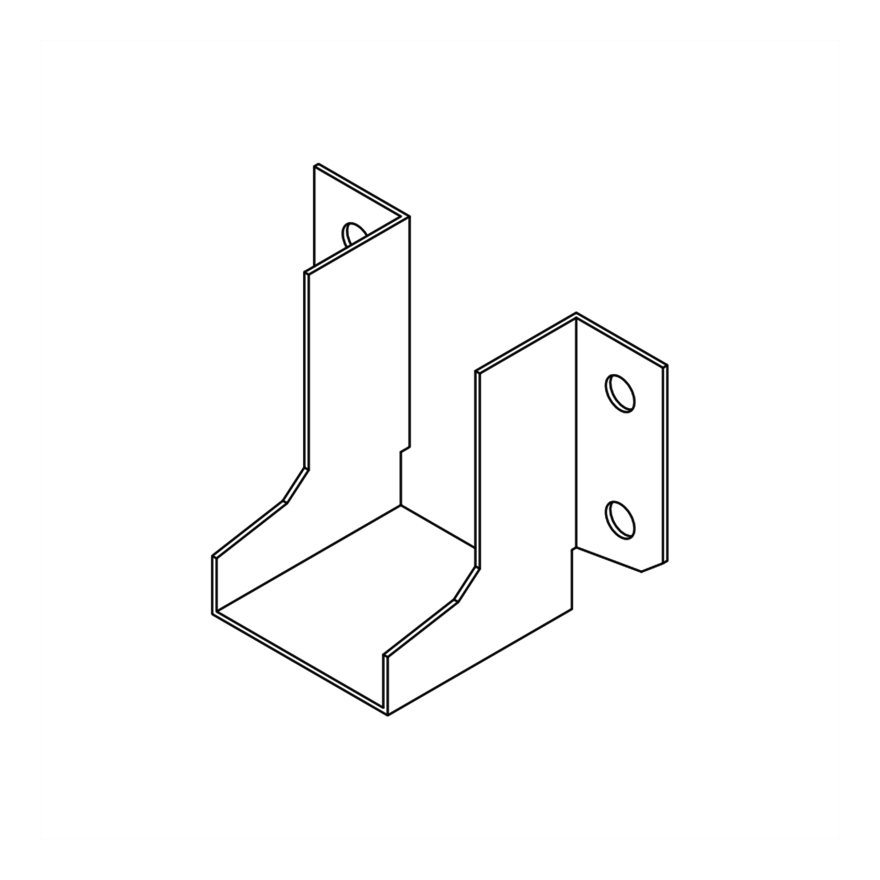

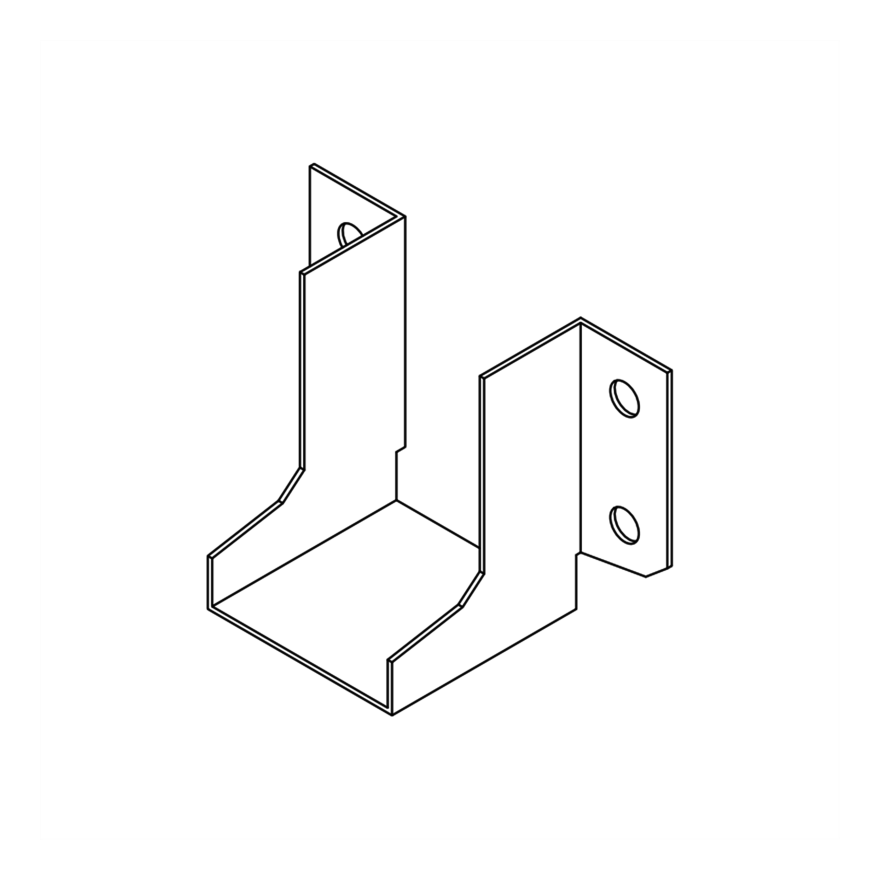

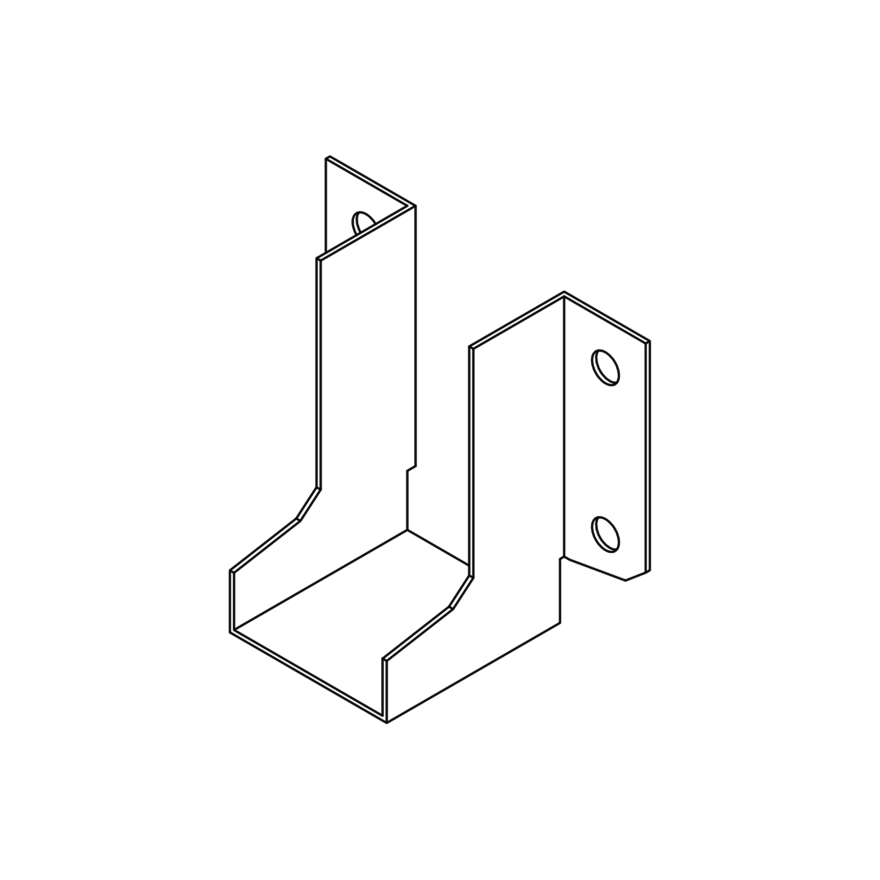

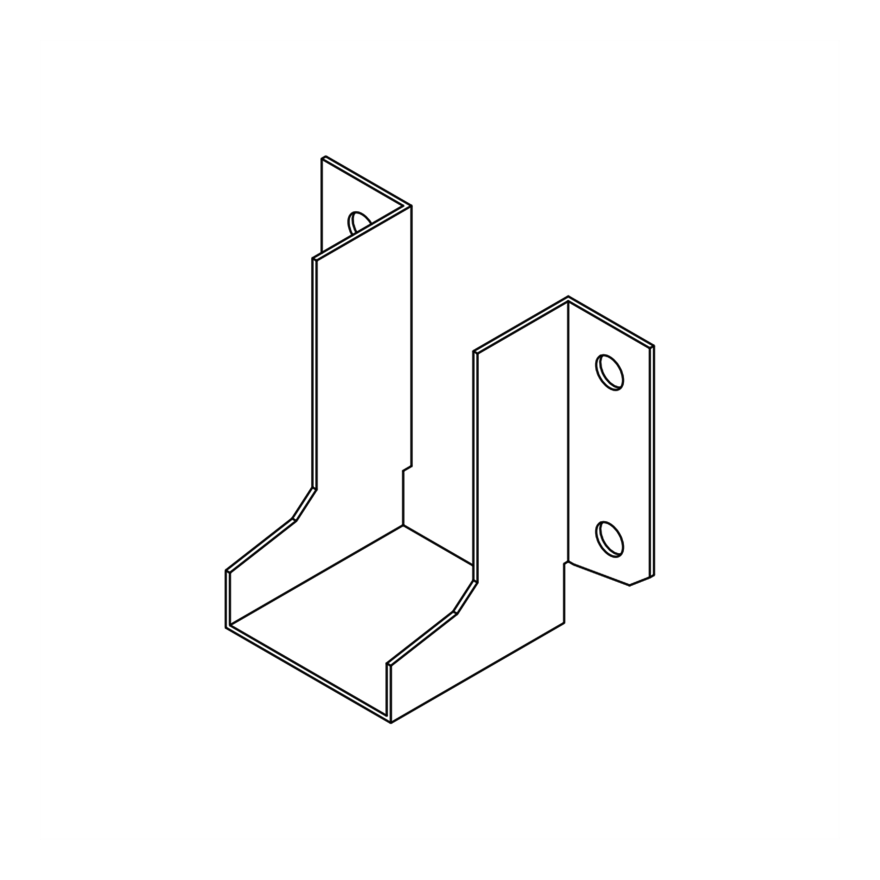

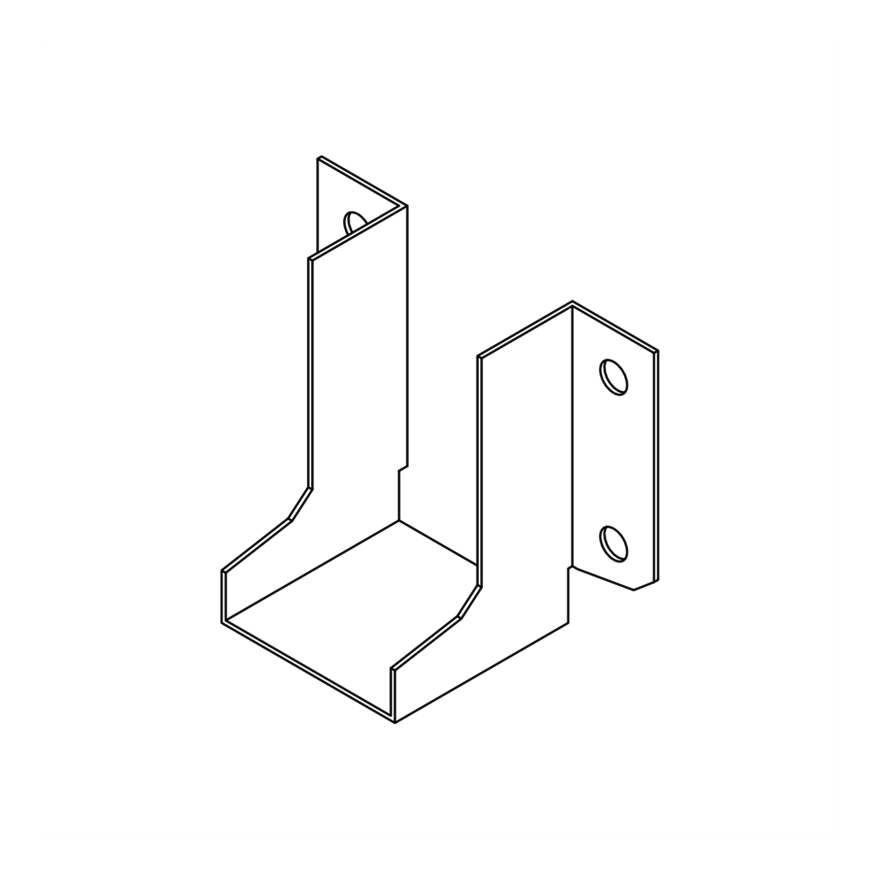

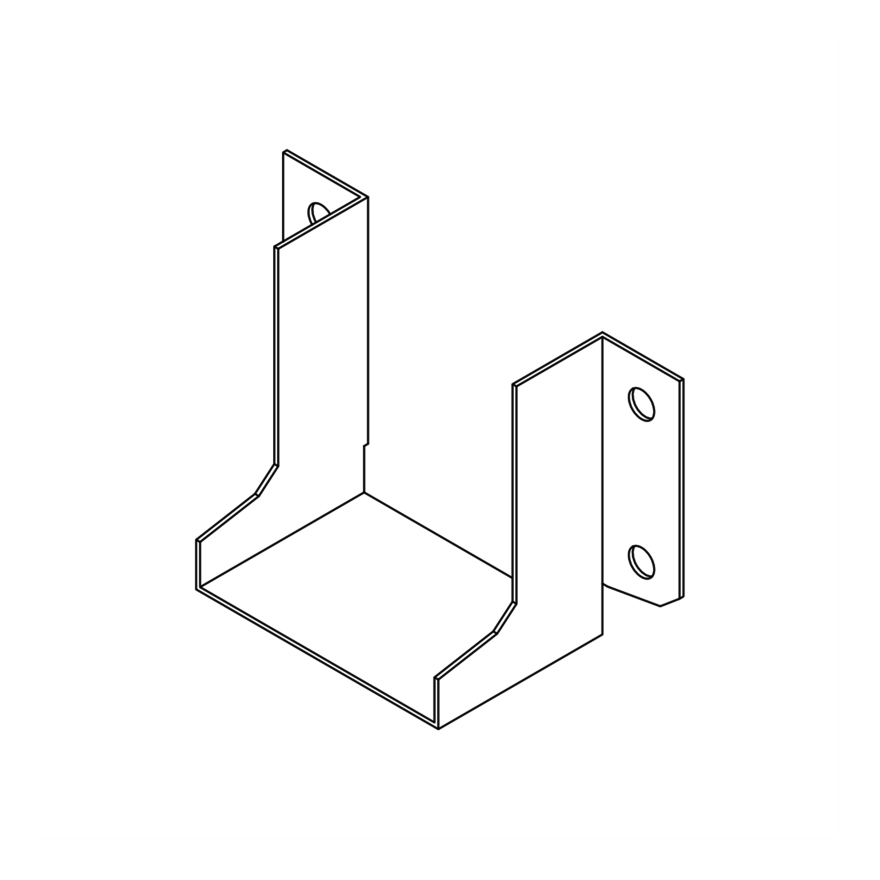

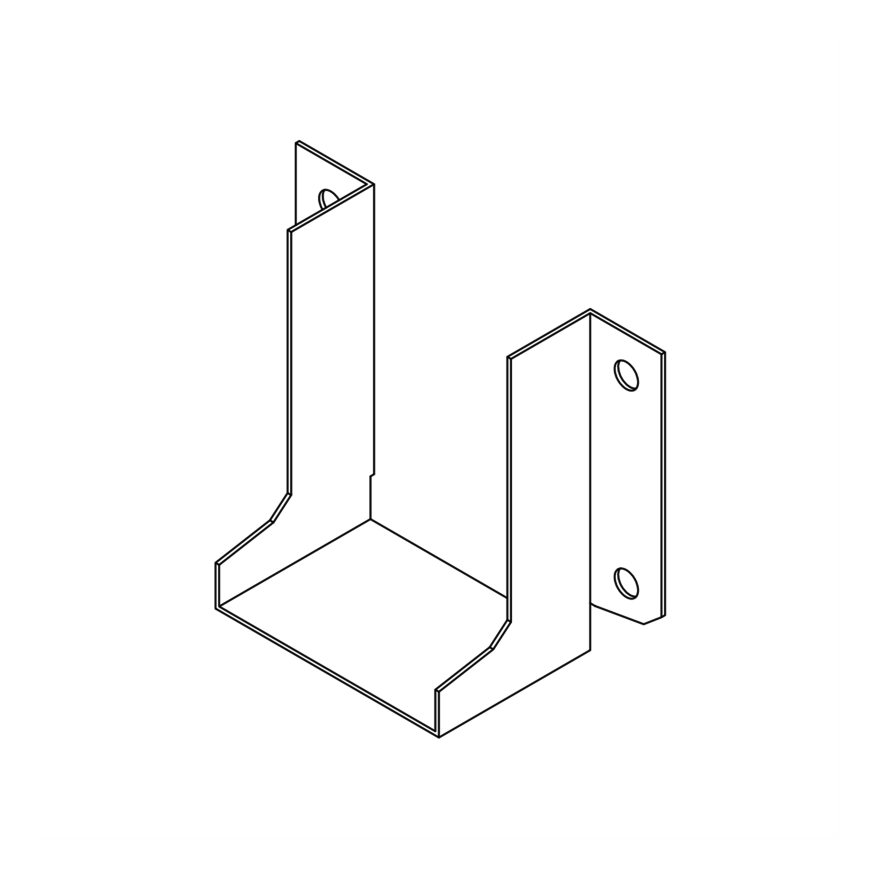

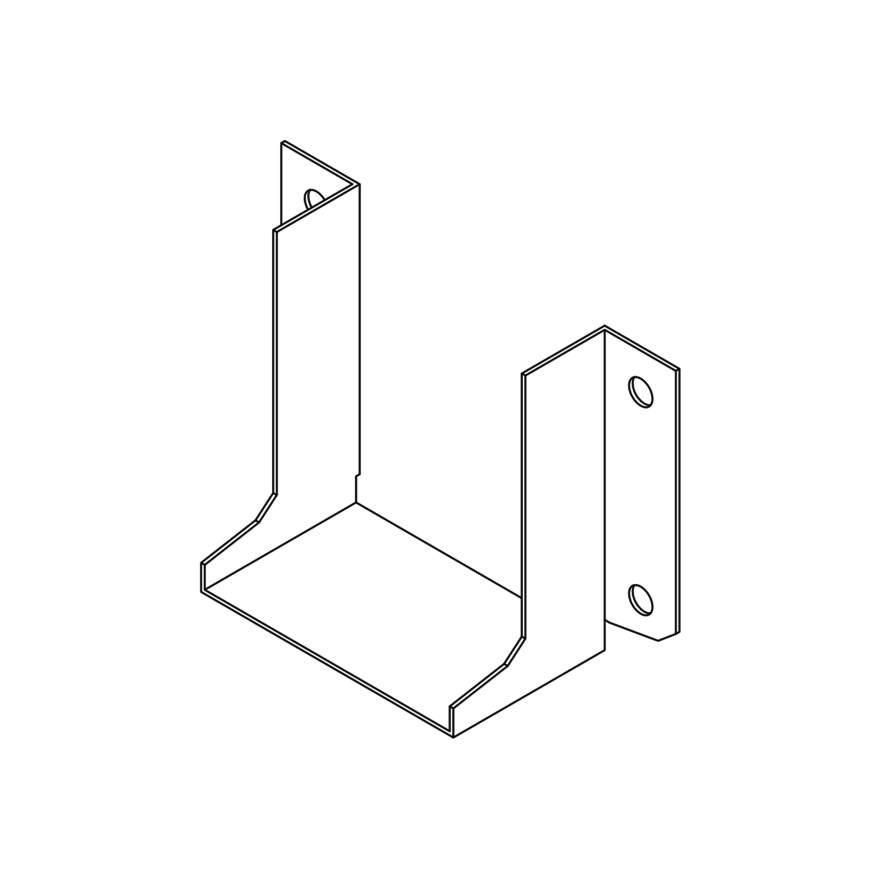

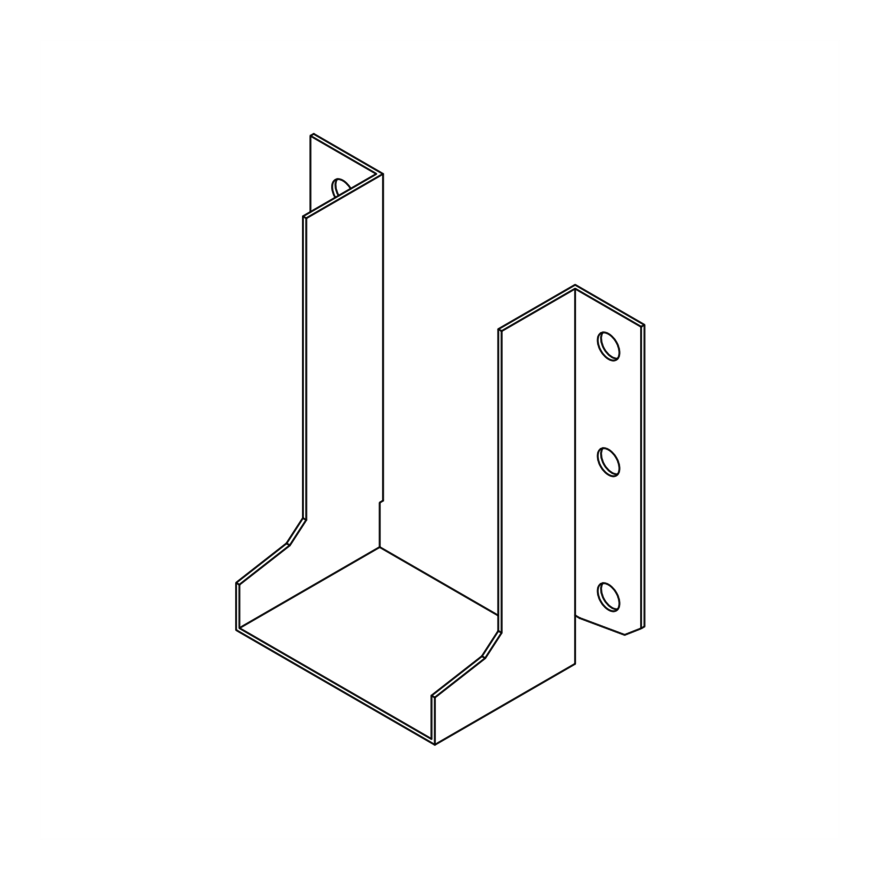

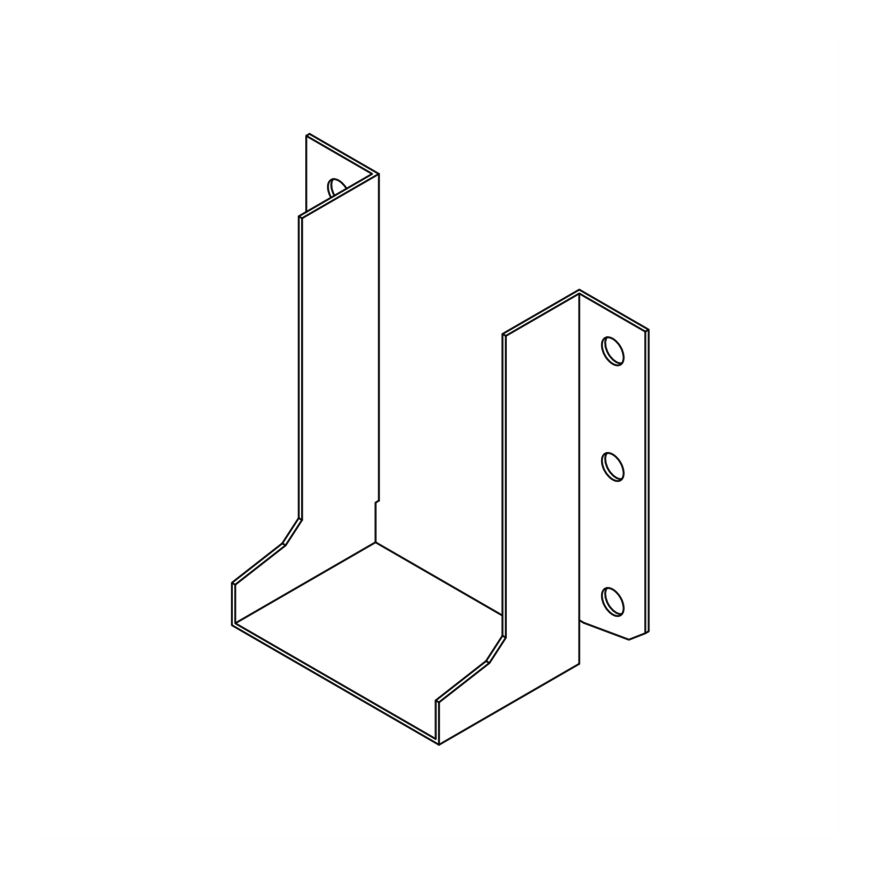

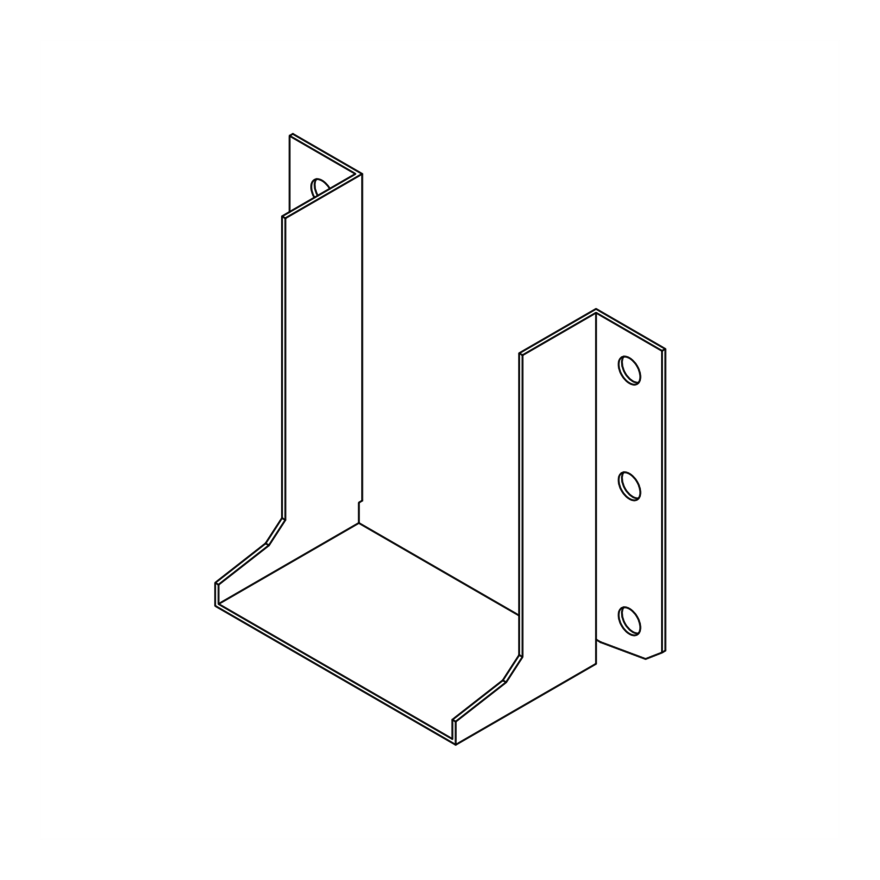

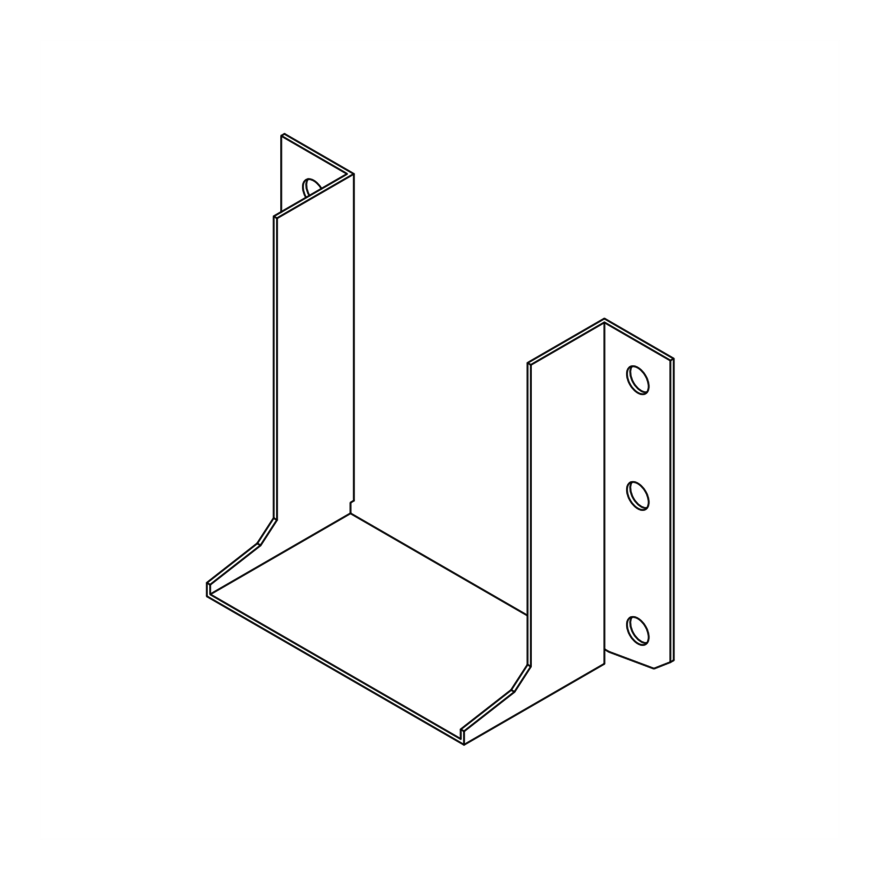

Suporte com abas exteriores

O SAE soube impôr-se na construção há alguns anos. A sua utilização abrange um vasto leque de aplicações. As montagens são fiáveis, sem necessidade de maquinaria e contribuem para a fiabilidade da obra.

Detalhes do produto

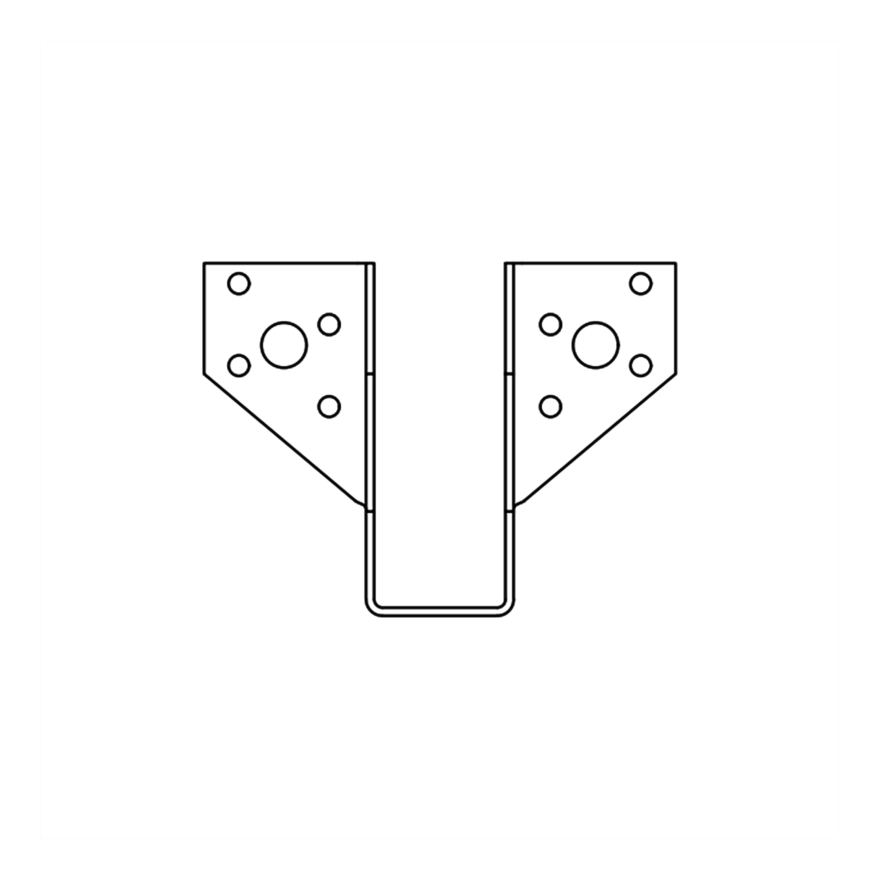

Características

Matéria

- Aço galvanizado S250GD + Z275 em conformidade com a norma NF EN 10346,

- Espessura : 2 mm.

Ventagens

- Instalação rápida e simples,

- Larguras à escolha consoante los intervalos indicados.

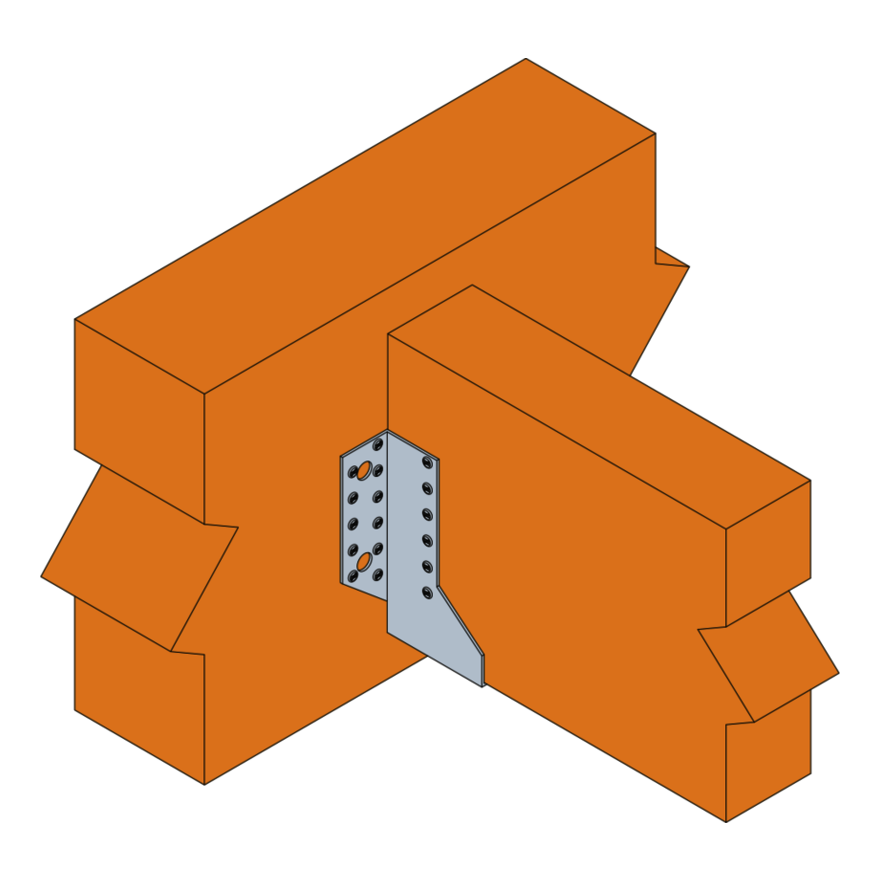

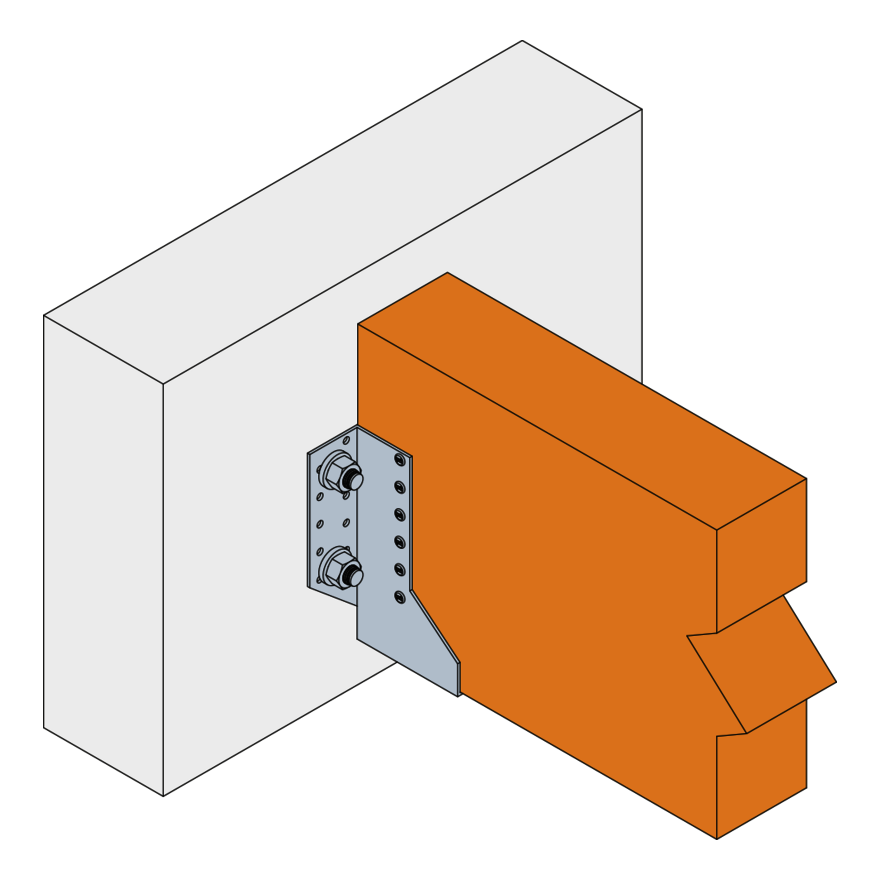

Aplicação

Suporte

- Elemento de suporte : madeira maciça, aglomerado de madeira, laminada colada, aço, betão,

- Elemento suportado : madeira maciça, aglomerado de madeira, laminada colada.

Áreas de utilização

- Barrotes, madres,

- Vigas lisas e pilar de revestimento de proteção,

- Batentes de varas,

- Reforço de montagens existentes.

Dados técnicos

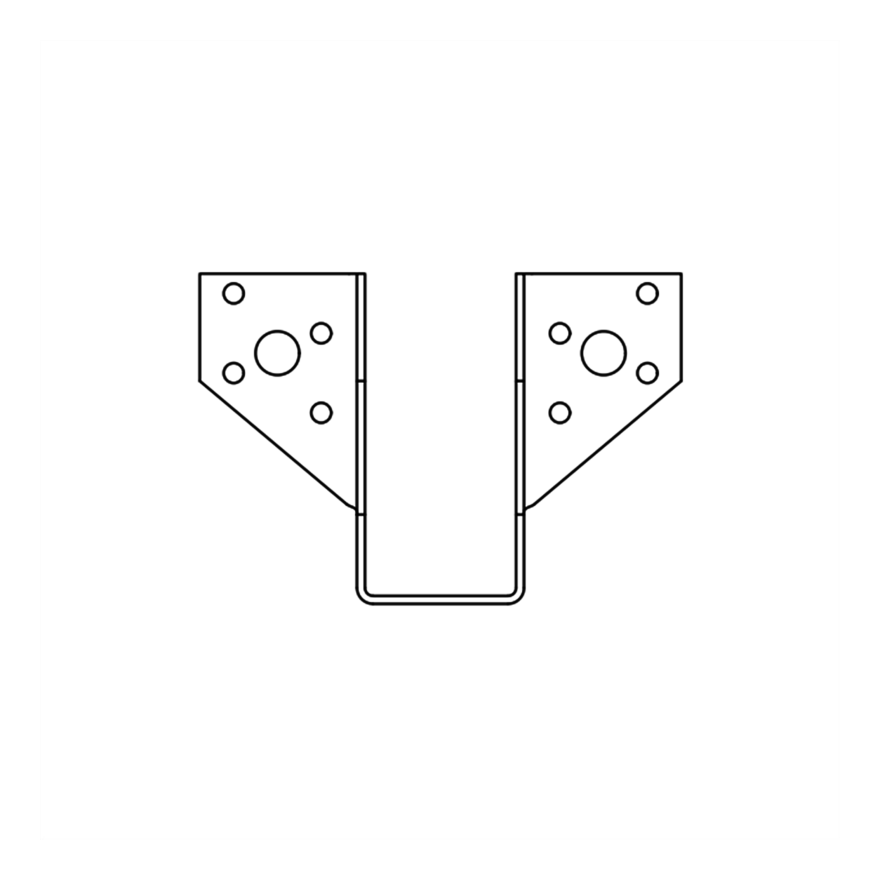

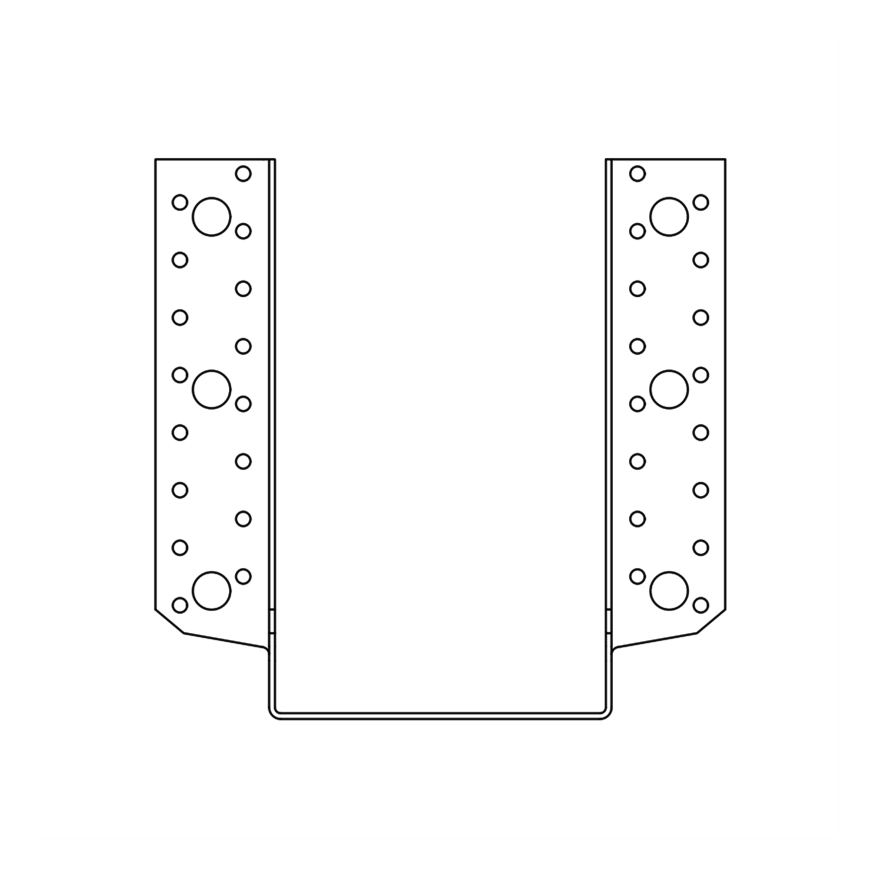

Desenvolvimentos e larguras

| Referência | Blank model [mm] | Larguras [mm] | Depth [mm] | Anchor on the header |

Fasteners on the header CNA4.0x50 or CSA5.0x40 |

Fasteners on the joist CNA4.0x50 or CSA5.0x40 |

|---|---|---|---|---|---|---|

| SAE200/2X | 200 | 24 - 80 | 84 | 2 Ø10 | 8 | 5 |

| SAE250/2X | 250 | 24 - 80 | 84 | 2 Ø10 | 12 | 7 |

| SAEL300/2X | 300 | 24 - 116 | 84 | 4 Ø12 | 18 | 10 |

| SAEL340/2X | 340 | 24 - 116 | 84 | 4 Ø12 | 22 | 12 |

| SAEL380/2X | 380 | 24 - 156 | 84 | 4 Ø12 | 22 | 12 |

| SAEL440/2X | 440 | 24 - 156 | 84 | 4 Ø12 | 28 | 15 |

| SAEL500/2X | 500 | 24 - 156 | 84 | 6 Ø12 | 34 | 15 |

Para mais informações sobre os valores das cargas em função da largura do suporte, contacte o departamento técnico.

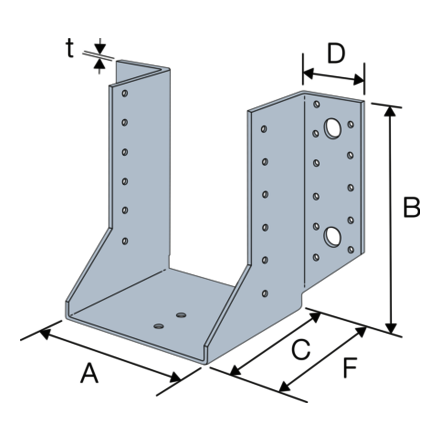

Dimensões e valores caraterísticos

| Referência | Portador [mm] | Dimensões e valores caraterísticos [mm] | Furos portador | Furos suportado | Peso [kg] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Larguras | Altura | A | B | C | D | F | t | Ø5 | Ø11 | Ø13 | Ø5 | ||||

| Larguras | Máx. | Larguras | Máx. | ||||||||||||

| SAE200/32/2 | 30 | 32 | 99 | 126 | 32 | 84 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/32/2 | 30 | 32 | 119 | 164 | 109 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/32/2 | 30 | 32 | 149 | 201 | 134 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE200/38/2 | 36 | 38 | 96 | 122 | 38 | 81 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/38/2 | 36 | 38 | 116 | 159 | 106 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/38/2 | 36 | 38 | 146 | 197 | 131 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/38/2 | 36 | 38 | 166 | 227 | 151 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE440/38/2 | 36 | 38 | 216 | 302 | 201 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE200/40/2 | 38 | 40 | 95 | 120 | 40 | 80 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.261 |

| SAE250/40/2 | 38 | 40 | 115 | 158 | 105 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/40/2 | 38 | 40 | 145 | 195 | 130 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/40/2 | 38 | 40 | 165 | 225 | 150 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE200/46/2 | 44 | 46 | 92 | 116 | 46 | 77 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/46/2 | 44 | 46 | 112 | 153 | 102 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE340/46/2 | 44 | 46 | 162 | 221 | 147 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE500/46/2 | 44 | 46 | 242 | 341 | 227 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.66 | |

| SAE200/50/2 | 48 | 50 | 90 | 113 | 50 | 75 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/50/2 | 48 | 50 | 110 | 150 | 100 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/50/2 | 48 | 50 | 140 | 188 | 125 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/50/2 | 48 | 50 | 160 | 218 | 145 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE500/50/2 | 48 | 50 | 240 | 338 | 225 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.66 | |

| SAE200/60/2 | 58 | 60 | 85 | 105 | 60 | 70 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/60/2 | 58 | 60 | 105 | 143 | 95 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/60/2 | 58 | 60 | 135 | 180 | 120 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/60/2 | 58 | 60 | 155 | 210 | 140 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE200/64/2 | 62 | 64 | 83 | 102 | 64 | 68 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/64/2 | 62 | 64 | 103 | 140 | 93 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/64/2 | 62 | 64 | 133 | 177 | 118 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/64/2 | 62 | 64 | 153 | 207 | 138 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE380/64/2 | 62 | 64 | 173 | 237 | 158 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 | |

| SAE380/66/2 | 64 | 66 | 172 | 236 | 66 | 157 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 |

| SAE440/66/2 | 64 | 66 | 202 | 281 | 187 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE200/70/2 | 68 | 70 | 80 | 98 | 70 | 65 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/70/2 | 68 | 70 | 100 | 135 | 90 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAE300/70/2 | 68 | 70 | 130 | 173 | 115 | 84 | 41.5 | 86 | 2 | 18 | - | 4 | 10 | 0.38 | |

| SAE340/70/2 | 68 | 70 | 150 | 203 | 135 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.43 | |

| SAE380/70/2 | 68 | 70 | 170 | 233 | 155 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 | |

| SAE440/70/2 | 68 | 70 | 200 | 278 | 185 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAEL300/72/2 | 70 | 72 | 129 | 171 | 72 | 114 | 84 | 41.5 | 86 | 2 | 16 | - | 4 | 8 | 0.38 |

| SAEL340/72/2 | 70 | 72 | 149 | 201 | 134 | 84 | 41.5 | 86 | 2 | 20 | - | 4 | 10 | 0.43 | |

| SAE380/72/2 | 70 | 72 | 169 | 231 | 154 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 | |

| SAE440/72/2 | 70 | 72 | 199 | 276 | 184 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE200/76/2 | 74 | 76 | 77 | 93 | 76 | 62 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/76/2 | 74 | 76 | 97 | 131 | 87 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAEL300/76/2 | 74 | 76 | 127 | 168 | 112 | 84 | 41.5 | 86 | 2 | 16 | - | 4 | 8 | 0.38 | |

| SAEL340/76/2 | 74 | 76 | 147 | 198 | 132 | 84 | 41.5 | 86 | 2 | 20 | - | 4 | 10 | 0.43 | |

| SAE380/76/2 | 74 | 76 | 167 | 228 | 152 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 | |

| SAE440/76/2 | 74 | 76 | 197 | 273 | 182 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE500/76/2 | 74 | 76 | 227 | 318 | 212 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.66 | |

| SAE200/80/2 | 78 | 80 | 75 | 90 | 80 | 60 | 84 | 41.5 | 86 | 2 | 8 | 2 | - | 5 | 0.26 |

| SAE250/80/2 | 78 | 80 | 95 | 128 | 85 | 84 | 41.5 | 86 | 2 | 12 | 2 | - | 7 | 0.33 | |

| SAEL300/80/2 | 78 | 80 | 125 | 165 | 110 | 84 | 41.5 | 86 | 2 | 16 | - | 4 | 8 | 0.38 | |

| SAEL340/80/2 | 78 | 80 | 145 | 195 | 130 | 84 | 41.5 | 86 | 2 | 20 | - | 4 | 10 | 0.43 | |

| SAE380/80/2 | 78 | 80 | 165 | 225 | 150 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.46 | |

| SAE440/80/2 | 78 | 80 | 195 | 270 | 180 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE500/80/2 | 78 | 80 | 225 | 315 | 210 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.65 | |

| SAE380/90/2 | 88 | 90 | 160 | 218 | 90 | 145 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 |

| SAE440/90/2 | 88 | 90 | 190 | 263 | 175 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE500/90/2 | 88 | 90 | 220 | 308 | 205 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.66 | |

| SAE380/92/2 | 90 | 92 | 159 | 216 | 92 | 144 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.49 |

| SAE440/95/2 | 93 | 95 | 188 | 259 | 95 | 172.5 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 |

| SAE500/95/2 | 93 | 95 | 218 | 304 | 202.5 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.65 | |

| SAEL300/100/2 | 98 | 100 | 115 | 150 | 100 | 100 | 84 | 41.5 | 86 | 2 | 16 | - | 4 | 8 | 0.38 |

| SAE380/100/2 | 98 | 100 | 155 | 210 | 140 | 84 | 41.5 | 86 | 2 | 22 | - | 4 | 12 | 0.48 | |

| SAE440/100/2 | 98 | 100 | 185 | 255 | 170 | 84 | 41.5 | 86 | 2 | 28 | - | 4 | 15 | 0.58 | |

| SAE500/100/2 | 98 | 100 | 215 | 300 | 200 | 84 | 41.5 | 86 | 2 | 34 | - | 6 | 18 | 0.65 | |

| SAEL500/115/2 | 113 | 115 | 208 | 289 | 115 | 192.5 | 84 | 41.5 | 86 | 2 | 32 | - | 6 | 16 | 0.65 |

| SAEL380/120/2 | 118 | 120 | 145 | 195 | 120 | 130 | 84 | 41.5 | 86 | 2 | 20 | - | 4 | 10 | 0.49 |

| SAEL440/120/2 | 118 | 120 | 175 | 240 | 160 | 84 | 41.5 | 86 | 2 | 26 | - | 4 | 13 | 0.58 | |

| SAEL500/120/2 | 118 | 120 | 205 | 285 | 190 | 84 | 41.5 | 86 | 2 | 32 | - | 6 | 16 | 0.65 | |

| SAEL440/136/2 | 134 | 136 | 167 | 228 | 136 | 152 | 84 | 41.5 | 86 | 2 | 26 | - | 4 | 13 | 0.58 |

| SAEL500/140/2 | 138 | 140 | 195 | 270 | 140 | 180 | 84 | 41.5 | 86 | 2 | 32 | - | 6 | 16 | 0.65 |

| SAEL500/150/2 | 148 | 150 | 190 | 263 | 150 | 175 | 84 | 41.5 | 86 | 2 | 32 | - | 6 | 16 | 0.65 |

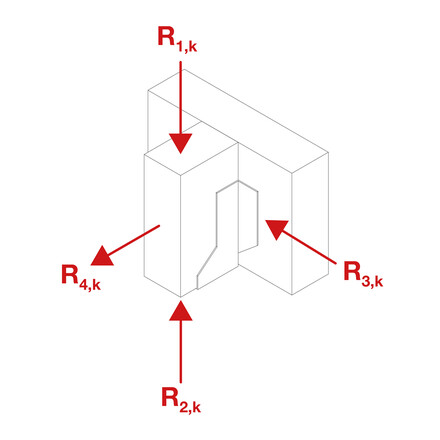

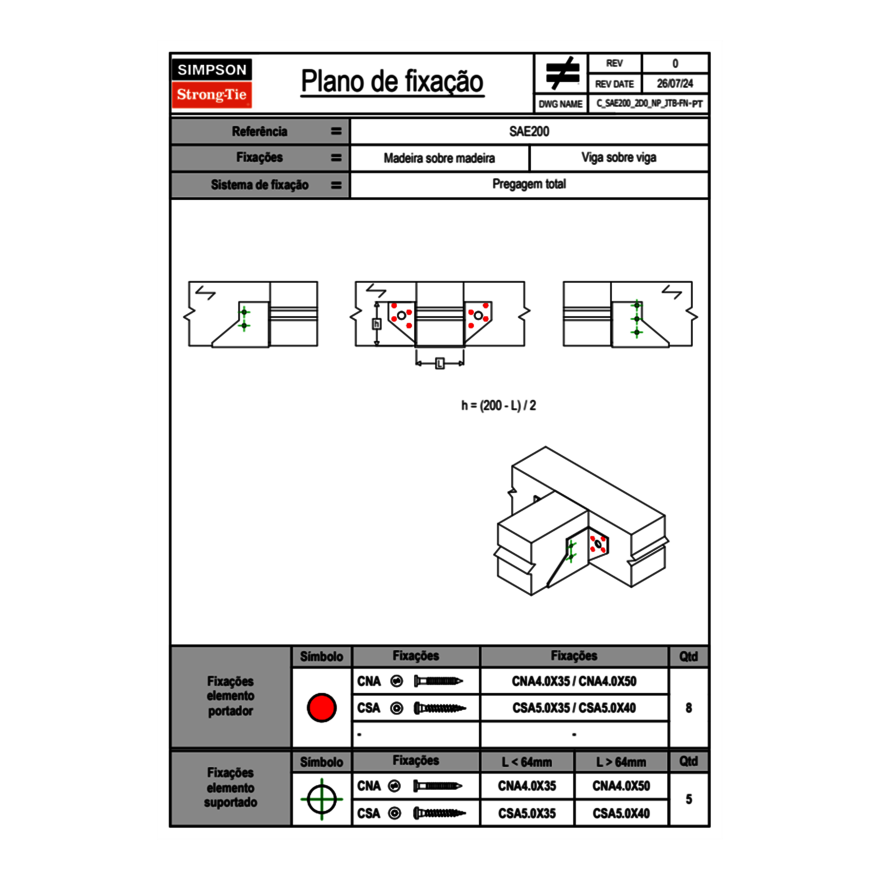

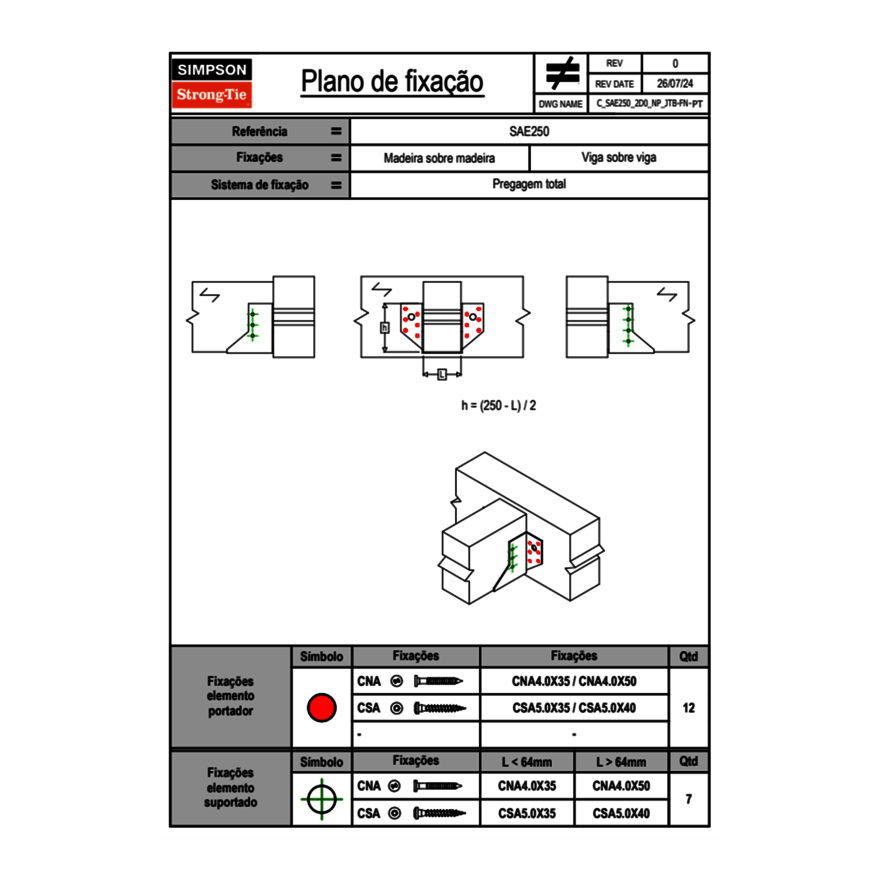

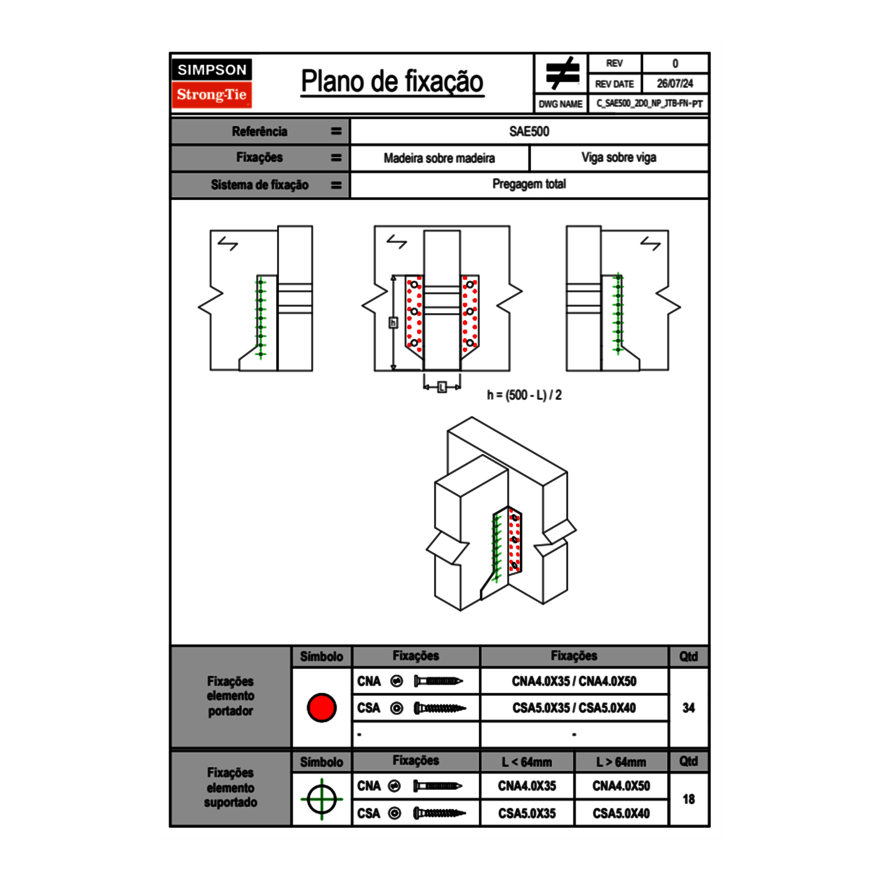

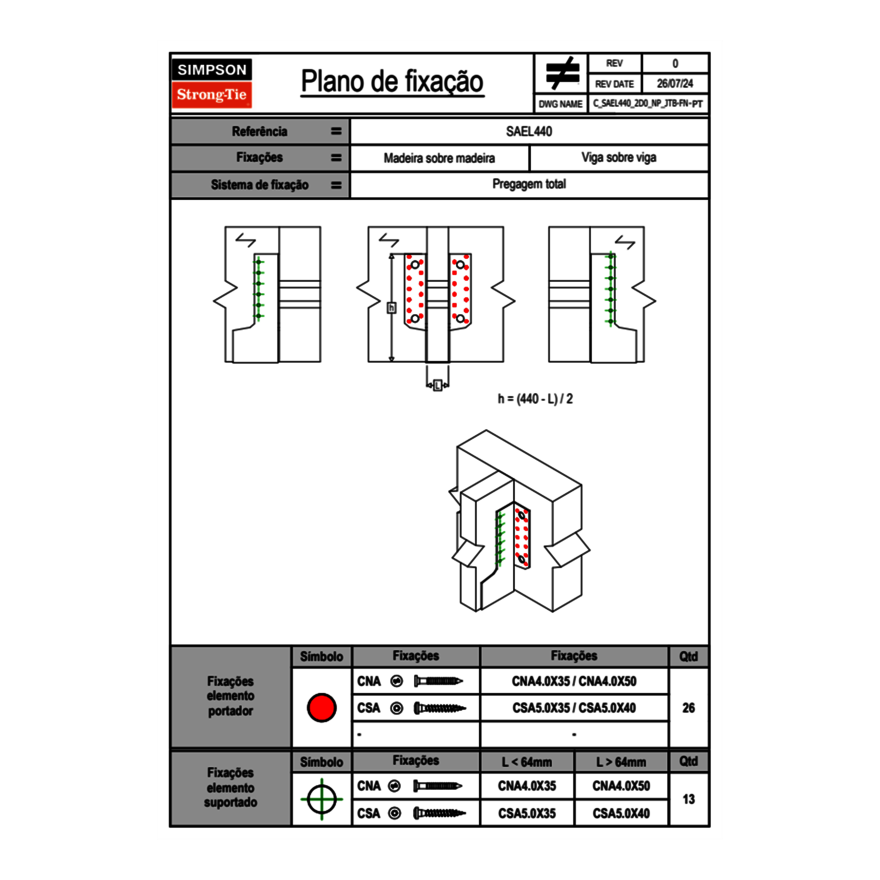

Valores caraterísticos - Madeira/Madeira - pregagem total

| Referência | Valores característicos - Madeira sobre madeira - pregagem total | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fixacões | Valores característicos - Madeira classe C24 [kN] | |||||||||

| Portador | Suportado | R1.k | R2.k | R3.k | R4.k | |||||

| Qdad | Qdad | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | |

| SAE200/32/2 | 8 | 5 | 6.3 | - | 3.3 | - | 0.9 | - | 2.5 | - |

| SAE250/32/2 | 12 | 7 | 9.8 | - | 6 | - | 1.5 | - | 3.7 | - |

| SAE300/32/2 | 18 | 10 | 16.1 | - | 11.3 | - | 3.3 | - | 5.5 | - |

| SAE200/38/2 | 8 | 5 | 6 | - | 3.3 | - | 0.9 | - | 2.5 | - |

| SAE250/38/2 | 12 | 7 | 9.4 | - | 6 | - | 1.5 | - | 3.7 | - |

| SAE300/38/2 | 18 | 10 | 15.6 | - | 11.3 | - | 3.3 | - | 5.5 | - |

| SAE340/38/2 | 22 | 12 | 20.2 | - | 15.6 | - | 4.3 | - | 6.7 | - |

| SAE440/38/2 | 28 | 15 | 28.5 | - | 22.9 | - | 5 | - | 8.6 | - |

| SAE200/40/2 | 8 | 5 | 5.9 | - | 3.3 | - | 0.9 | - | 2.5 | - |

| SAE250/40/2 | 12 | 7 | 9.3 | - | 6 | - | 1.5 | - | 3.7 | - |

| SAE300/40/2 | 18 | 10 | 15.4 | - | 11.3 | - | 3.3 | - | 5.5 | - |

| SAE340/40/2 | 22 | 12 | 20 | - | 15.6 | - | 4.4 | - | 6.7 | - |

| SAE200/46/2 | 8 | 5 | 5.5 | - | 3.3 | - | 0.9 | - | 2.5 | - |

| SAE250/46/2 | 12 | 7 | 8.9 | - | 6 | - | 1.5 | - | 3.7 | - |

| SAE340/46/2 | 22 | 12 | 19.5 | - | 15.6 | - | 4.4 | - | 6.7 | - |

| SAE500/46/2 | 34 | 18 | 33.5 | - | 30.2 | - | 6.2 | - | 10.4 | - |

| SAE200/50/2 | 8 | 5 | 5.3 | - | 3.3 | - | 0.9 | - | 2.5 | - |

| SAE250/50/2 | 12 | 7 | 8.6 | - | 6 | - | 1.5 | - | 3.7 | - |

| SAE300/50/2 | 18 | 10 | 14.5 | - | 11.3 | - | 3.3 | - | 5.5 | - |

| SAE340/50/2 | 22 | 12 | 19.1 | - | 15.6 | - | 4.4 | - | 6.7 | - |

| SAE500/50/2 | 34 | 18 | 33.5 | - | 30.2 | - | 6.6 | - | 10.4 | - |

| SAE200/60/2 | 8 | 5 | 4.7 | 7.4 | 3.3 | 5.3 | 0.9 | 1.3 | 2.5 | 3.9 |

| SAE250/60/2 | 12 | 7 | 7.8 | 12.1 | 6 | 9.4 | 1.5 | 2.1 | 3.7 | 5.9 |

| SAE300/60/2 | 18 | 10 | 13.6 | 20.8 | 11.3 | 17.6 | 3.3 | 4.4 | 5.5 | 8.8 |

| SAE340/60/2 | 22 | 12 | 18.1 | 27.4 | 15.6 | 24 | 4.4 | 5.9 | 6.7 | 10.8 |

| SAE200/64/2 | 8 | 5 | 4.5 | 7 | 3.3 | 5.3 | 0.9 | 1.3 | 2.5 | 3.9 |

| SAE250/64/2 | 12 | 7 | 7.5 | 11.7 | 6 | 9.4 | 1.5 | 2.1 | 3.7 | 5.9 |

| SAE300/64/2 | 18 | 10 | 13.2 | 20.3 | 11.3 | 17.6 | 3.4 | 4.4 | 5.5 | 8.8 |

| SAE340/64/2 | 22 | 12 | 17.7 | 26.9 | 15.6 | 24 | 4.5 | 5.9 | 6.7 | 10.8 |

| SAE380/64/2 | 22 | 12 | 21.5 | 31 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE380/66/2 | 22 | 12 | 21.3 | 31 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE440/66/2 | 28 | 15 | 28.5 | 37.7 | 22.9 | 33.2 | 5.5 | 7.2 | 8.6 | 13.7 |

| SAE200/70/2 | 8 | 5 | 4.1 | 6.5 | 3.3 | 5.3 | 0.9 | 1.3 | 2.5 | 3.9 |

| SAE250/70/2 | 12 | 7 | 7.1 | 11 | 6 | 9.4 | 1.5 | 2.1 | 3.7 | 5.9 |

| SAE300/70/2 | 18 | 10 | 12.7 | 19.5 | 11.3 | 17.6 | 3.4 | 4.4 | 5.5 | 8.8 |

| SAE340/70/2 | 22 | 12 | 17.1 | 26 | 15.6 | 24 | 3.8 | 5.9 | 6.7 | 10.8 |

| SAE380/70/2 | 22 | 12 | 21 | 31 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE440/70/2 | 28 | 15 | 28.5 | 37.7 | 22.9 | 33.2 | 5.5 | 7.2 | 8.6 | 13.7 |

| SAEL300/72/2 | 16 | 8 | 12.4 | 18.9 | 9.4 | 14.6 | 2.6 | 3.4 | 4.9 | 7.8 |

| SAEL340/72/2 | 20 | 10 | 16.7 | 25.3 | 13.4 | 20.7 | 3.6 | 4.8 | 6.1 | 9.8 |

| SAE380/72/2 | 22 | 12 | 20.8 | 31 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE440/72/2 | 28 | 15 | 28.5 | 37.7 | 22.9 | 33.2 | 5.5 | 7.3 | 8.6 | 13.7 |

| SAE200/76/2 | 8 | 5 | 3.8 | 5.9 | 3.3 | 5.3 | 0.9 | 1.4 | 2.5 | 3.9 |

| SAE250/76/2 | 12 | 7 | 6.6 | 10.3 | 6 | 9.4 | 1.5 | 2.1 | 3.7 | 5.9 |

| SAEL300/76/2 | 16 | 8 | 12 | 18.4 | 9.4 | 14.6 | 2.6 | 3.4 | 4.9 | 7.8 |

| SAEL340/76/2 | 20 | 10 | 16.3 | 24.7 | 13.4 | 20.7 | 3.6 | 4.8 | 6.1 | 9.8 |

| SAE380/76/2 | 22 | 12 | 20.4 | 30.5 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE440/76/2 | 28 | 15 | 28.1 | 37.7 | 22.9 | 33.2 | 5.5 | 7.3 | 8.6 | 13.7 |

| SAE500/76/2 | 34 | 18 | 33.5 | 44.3 | 30.2 | 39.9 | 6.6 | 9.5 | 10.4 | 16.7 |

| SAE200/80/2 | 8 | 5 | 3.5 | 5.6 | 3.3 | 5.3 | 0.9 | 1.4 | 2.5 | 3.9 |

| SAE250/80/2 | 12 | 7 | 6.3 | 9.9 | 6 | 9.4 | 1.5 | 2.1 | 3.7 | 5.9 |

| SAEL300/80/2 | 16 | 8 | 11.7 | 17.9 | 9.4 | 14.6 | 2.6 | 3.4 | 4.9 | 7.8 |

| SAEL340/80/2 | 20 | 10 | 15.9 | 24.2 | 13.4 | 20.7 | 3.6 | 4.8 | 6.1 | 9.8 |

| SAE380/80/2 | 22 | 12 | 20 | 30 | 15.6 | 24 | 3.8 | 5.1 | 6.7 | 10.8 |

| SAE440/80/2 | 28 | 15 | 27.7 | 37.7 | 22.9 | 33.2 | 5.5 | 7.3 | 8.6 | 13.7 |

| SAE500/80/2 | 34 | 18 | 33.5 | 44.3 | 30.2 | 39.9 | 6.6 | 9.5 | 10.4 | 16.7 |

| SAE380/90/2 | 22 | 12 | 19.1 | 28.8 | 15.6 | 24 | 3.8 | 5.2 | 6.7 | 10.8 |

| SAE440/90/2 | 28 | 15 | 26.7 | 37.7 | 22.9 | 33.2 | 5.6 | 7.3 | 8.6 | 13.7 |

| SAE500/90/2 | 34 | 18 | 33.5 | 44.3 | 30.2 | 39.9 | 6.6 | 9.6 | 10.4 | 16.7 |

| SAE380/92/2 | 22 | 12 | 18.9 | 28.5 | 15.6 | 24 | 3.8 | 5.2 | 6.7 | 10.8 |

| SAE440/95/2 | 28 | 15 | 26.2 | 37.7 | 22.9 | 33.2 | 5.6 | 7.4 | 8.6 | 13.7 |

| SAE500/95/2 | 34 | 18 | 33.5 | 44.3 | 30.2 | 39.9 | 6.6 | 9.6 | 10.4 | 16.7 |

| SAEL300/100/2 | 16 | 8 | 9.9 | 15.3 | 9.4 | 14.6 | 2.6 | 3.5 | 4.9 | 7.8 |

| SAE380/100/2 | 22 | 12 | 18.1 | 27.4 | 15.6 | 24 | 3.8 | 5.2 | 6.7 | 10.8 |

| SAE440/100/2 | 28 | 15 | 25.7 | 37.7 | 22.9 | 33.2 | 5.6 | 7.4 | 8.6 | 13.7 |

| SAE500/100/2 | 34 | 18 | 33.5 | 44.3 | 30.2 | 39.9 | 6.6 | 9.6 | 10.4 | 16.7 |

| SAEL500/115/2 | 32 | 16 | 30.2 | 39.9 | 26.8 | 35.5 | 6.6 | 8.5 | 10.4 | 15.7 |

| SAEL380/120/2 | 20 | 10 | 15.9 | 24.2 | 13.4 | 20.7 | 3.8 | 4.2 | 6.7 | 9.8 |

| SAEL440/120/2 | 26 | 13 | 23.1 | 33.2 | 20.4 | 28.8 | 4.7 | 6.3 | 8 | 12.7 |

| SAEL500/120/2 | 32 | 16 | 30.2 | 39.9 | 26.8 | 35.5 | 6.6 | 8.5 | 10.4 | 15.7 |

| SAEL440/136/2 | 26 | 13 | 21.4 | 32.5 | 20.4 | 28.8 | 4.8 | 6.3 | 8 | 12.7 |

| SAEL500/140/2 | 32 | 16 | 29 | 39.9 | 26.8 | 35.5 | 6.6 | 8.5 | 10.4 | 15.7 |

| SAEL500/150/2 | 32 | 16 | 27.8 | 39.9 | 26.8 | 35.5 | 6.6 | 8.5 | 10.4 | 15.7 |

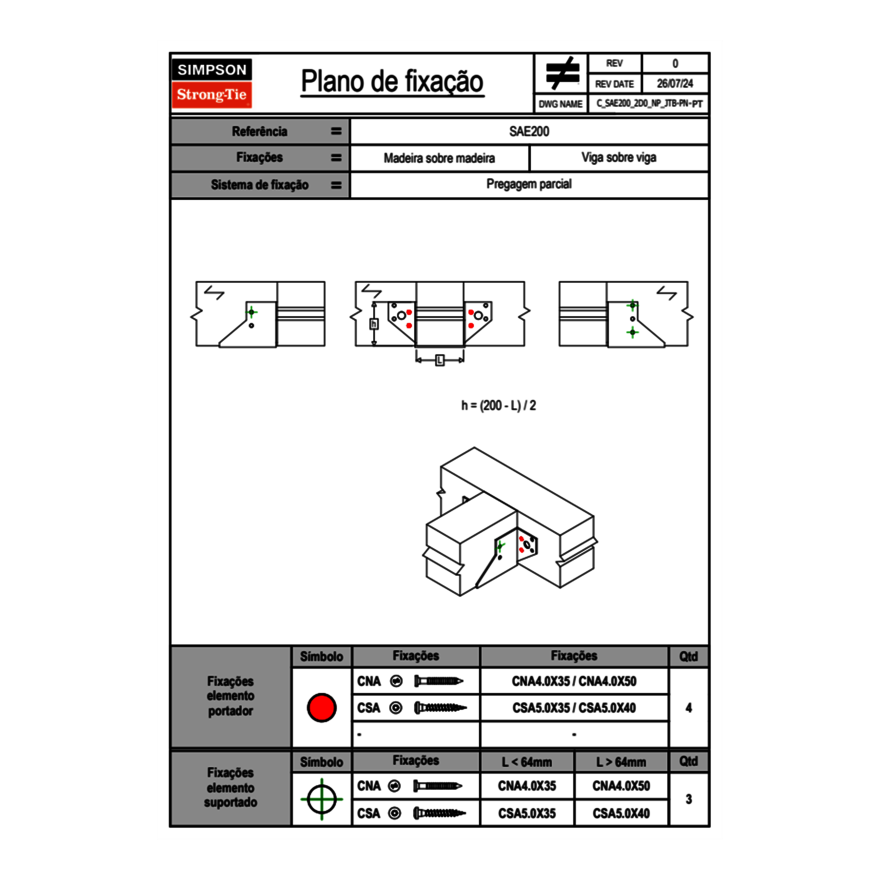

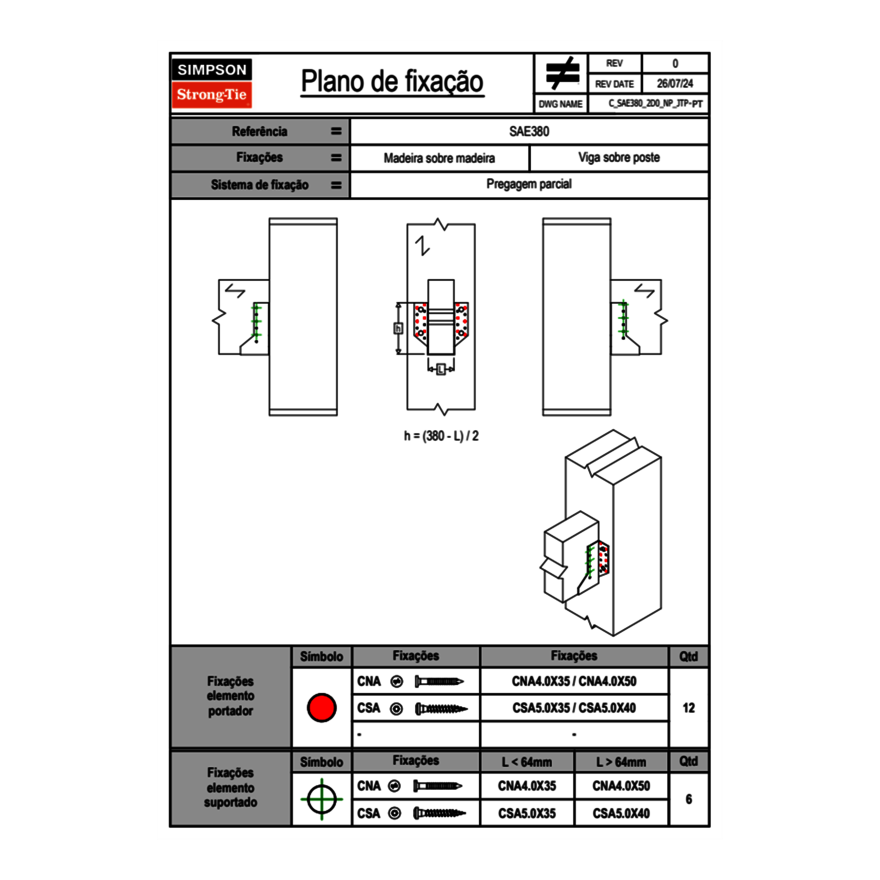

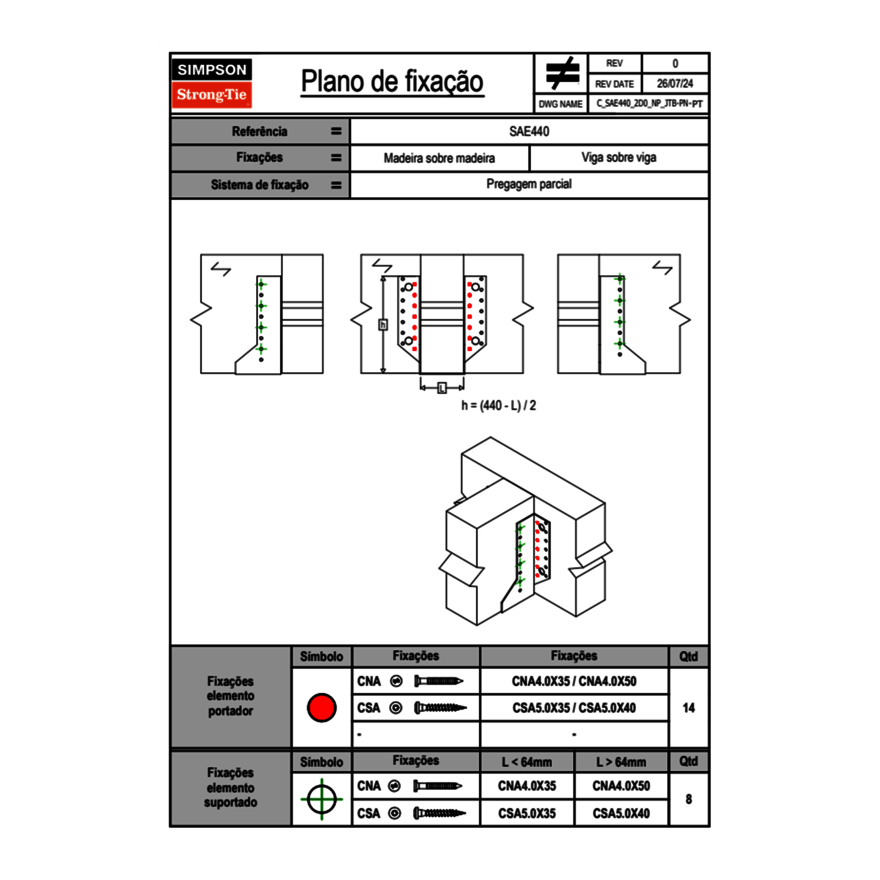

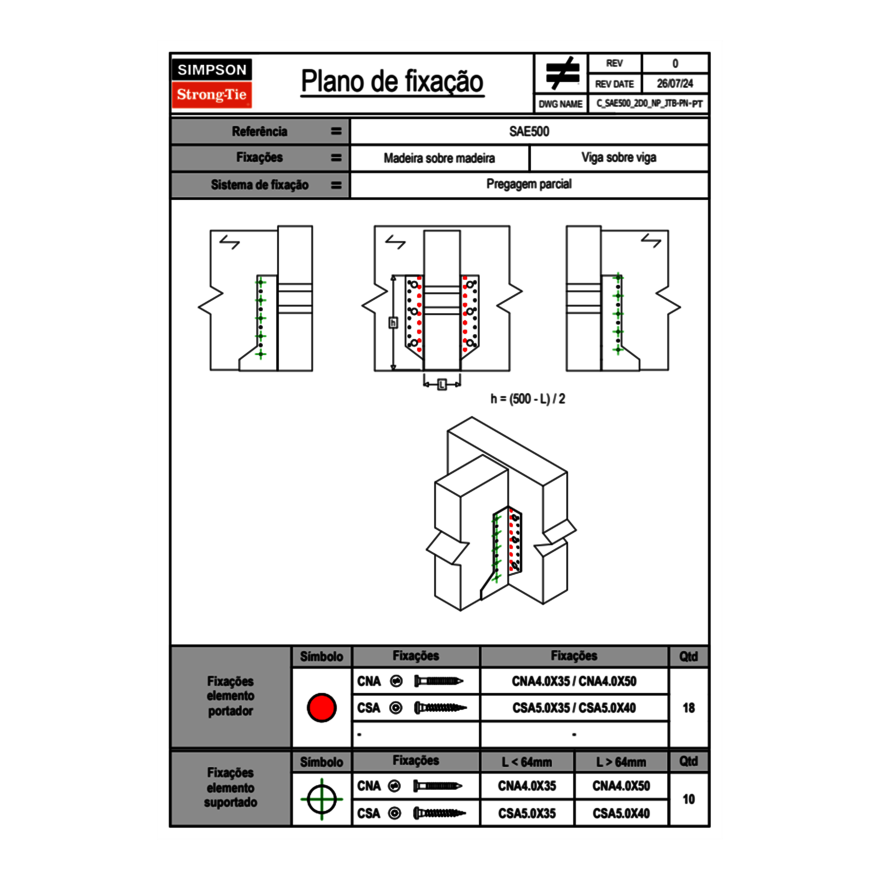

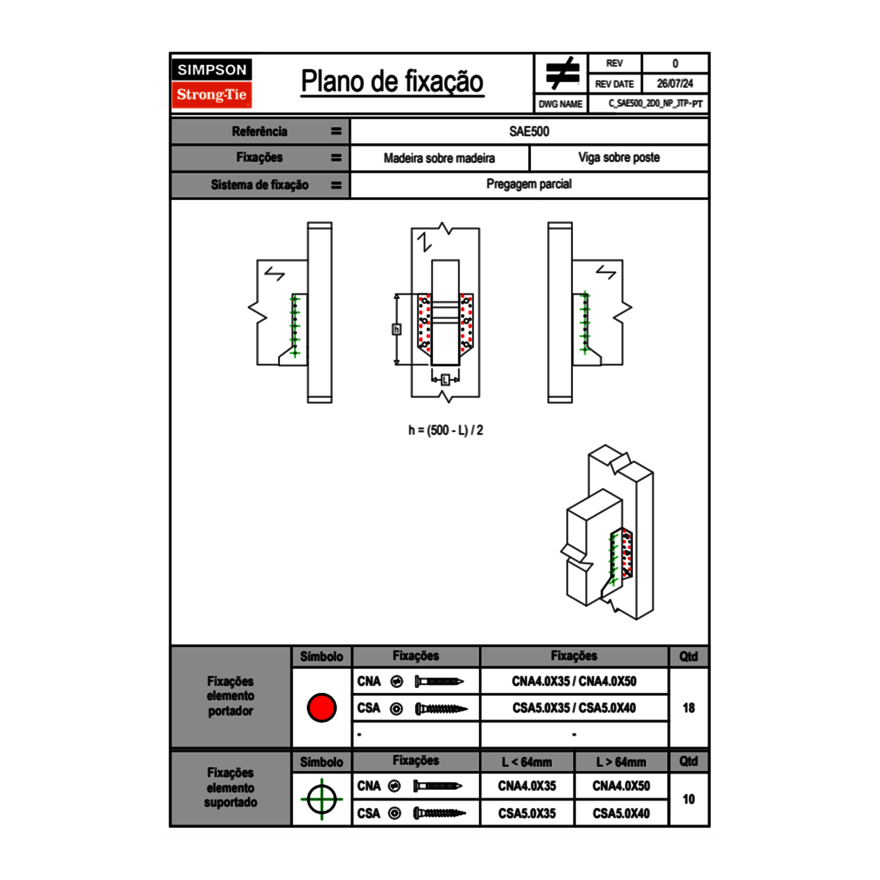

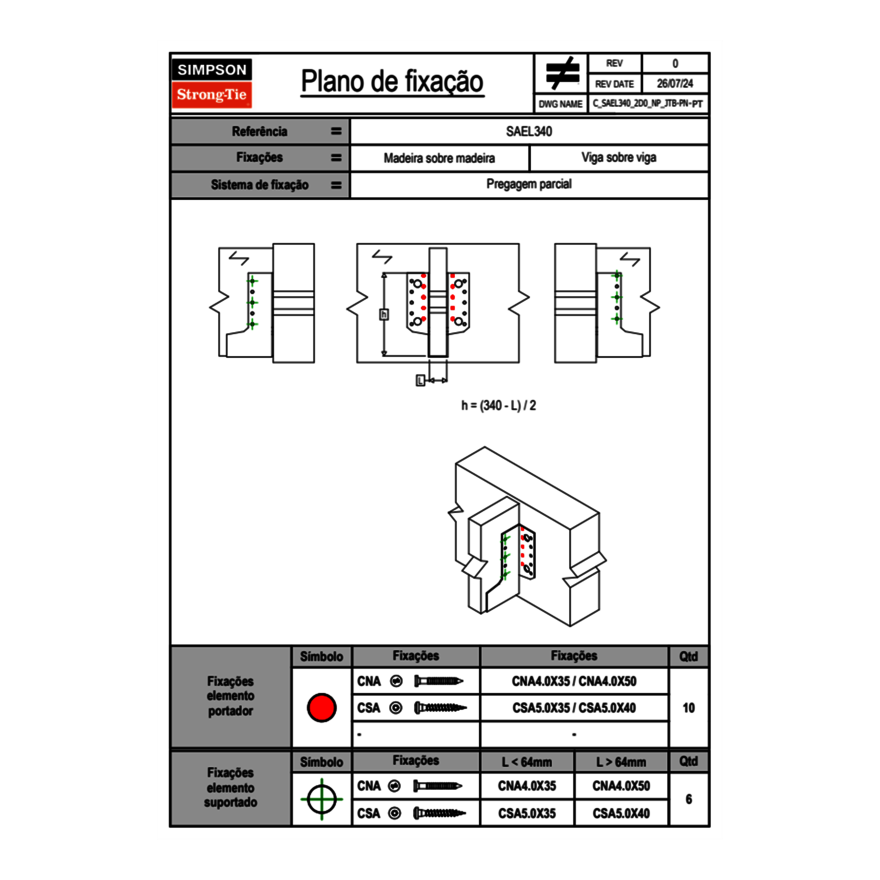

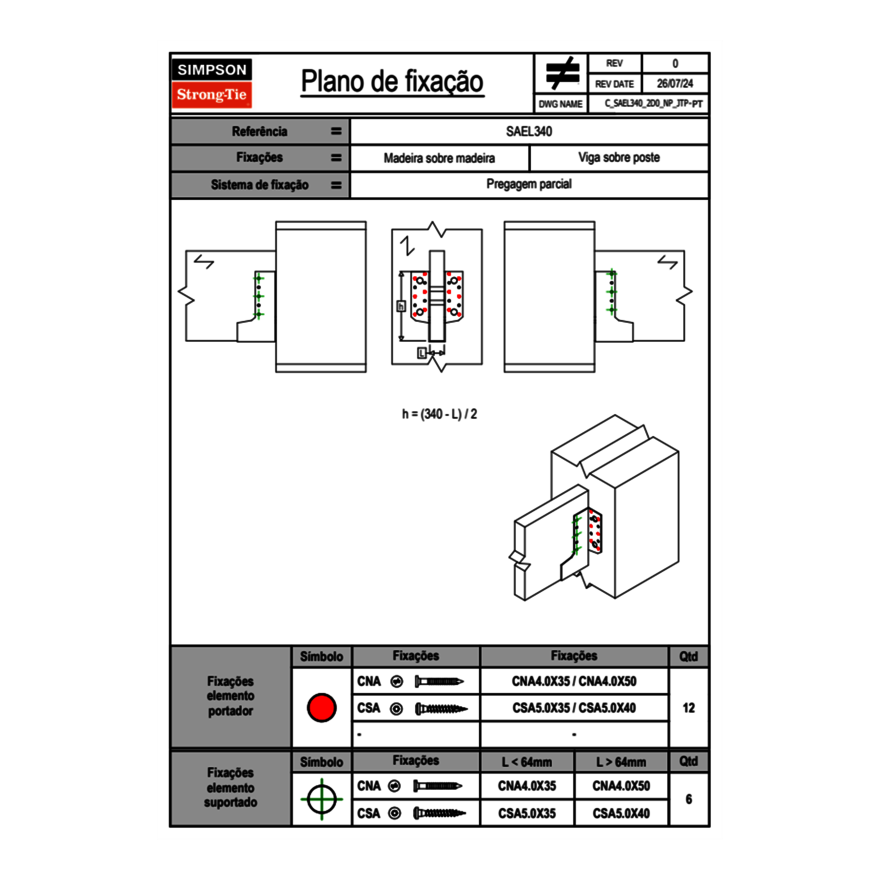

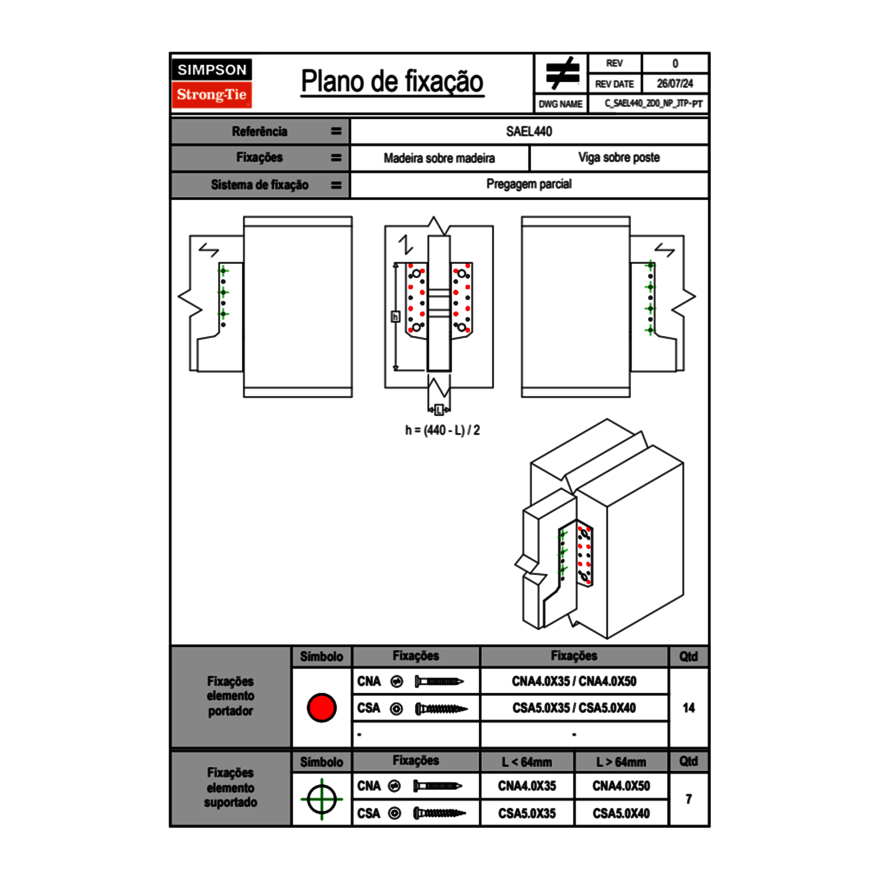

Valores caraterísticos - Madeira/madeira - Pregagem parcial

| Referência | Characteristic capacities - Timber to timber - Partial nailing - | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fixacões | Valores característicos - Madeira classe C24 [kN] | |||||||||

| Portador | Suportado | R1.k | R2.k | R3.k | R4.k | |||||

| Qdad | Qdad | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | |

| SAE200/32/2 | 4 | 4 | 3.7 | - | 1.8 | - | 0.4 | - | 1.2 | - |

| SAE250/32/2 | 6 | 4 | 5.8 | - | 2.5 | - | 0.8 | - | 1.8 | - |

| SAE300/32/2 | 10 | 6 | 9.1 | - | 6.5 | - | 1.1 | - | 3.1 | - |

| SAE200/38/2 | 4 | 4 | 3.5 | - | 1.8 | - | 0.5 | - | 1.2 | - |

| SAE250/38/2 | 6 | 4 | 5.6 | - | 2.5 | - | 0.8 | - | 1.8 | - |

| SAE300/38/2 | 10 | 6 | 8.8 | - | 6.5 | - | 1.1 | - | 3.1 | - |

| SAE340/38/2 | 12 | 6 | 11.9 | - | 8.7 | - | 1.8 | - | 3.7 | - |

| SAE440/38/2 | 14 | 8 | 16.8 | - | 11 | - | 1.9 | - | 4.3 | - |

| SAE200/40/2 | 4 | 4 | 3.5 | - | 1.8 | - | 0.5 | - | 1.2 | - |

| SAE250/40/2 | 6 | 4 | 5.6 | - | 2.5 | - | 0.8 | - | 1.8 | - |

| SAE300/40/2 | 10 | 6 | 8.7 | - | 6.5 | - | 1.1 | - | 3.1 | - |

| SAE340/40/2 | 12 | 6 | 11.8 | - | 8.7 | - | 1.9 | - | 3.7 | - |

| SAE200/46/2 | 4 | 4 | 3.3 | - | 1.8 | - | 0.5 | - | 1.2 | - |

| SAE250/46/2 | 6 | 4 | 5.4 | - | 2.5 | - | 0.8 | - | 1.8 | - |

| SAE340/46/2 | 12 | 6 | 11.5 | - | 8.7 | - | 2.1 | - | 3.7 | - |

| SAE500/46/2 | 18 | 10 | 20.1 | - | 16.8 | - | 2.3 | - | 5.5 | - |

| SAE200/50/2 | 4 | 4 | 3.2 | - | 1.8 | - | 0.5 | - | 1.2 | - |

| SAE250/50/2 | 6 | 4 | 5.2 | - | 2.5 | - | 0.8 | - | 1.8 | - |

| SAE300/50/2 | 10 | 6 | 8.2 | - | 6.5 | - | 1.1 | - | 3.1 | - |

| SAE340/50/2 | 12 | 6 | 11.3 | - | 8.7 | - | 2.2 | - | 3.7 | - |

| SAE500/50/2 | 18 | 10 | 20.1 | - | 16.8 | - | 2.5 | - | 5.5 | - |

| SAE200/60/2 | 4 | 4 | 2.9 | 4.5 | 1.8 | 2.8 | 0.5 | 0.7 | 1.2 | 2 |

| SAE250/60/2 | 6 | 4 | 4.9 | 7.4 | 2.5 | 3.9 | 0.8 | 1.1 | 1.8 | 2.9 |

| SAE300/60/2 | 10 | 6 | 7.7 | 11.7 | 6.5 | 10 | 1.2 | 1.5 | 3.1 | 4.9 |

| SAE340/60/2 | 12 | 6 | 10.8 | 16.2 | 8.7 | 13.3 | 2.5 | 3.6 | 3.7 | 5.9 |

| SAE200/64/2 | 4 | 4 | 2.8 | 4.3 | 1.8 | 2.8 | 0.5 | 0.7 | 1.2 | 2 |

| SAE250/64/2 | 6 | 4 | 4.7 | 7.2 | 2.5 | 3.9 | 0.8 | 1.1 | 1.8 | 2.9 |

| SAE300/64/2 | 10 | 6 | 7.4 | 11.4 | 6.5 | 10 | 1.2 | 1.5 | 3.1 | 4.9 |

| SAE340/64/2 | 12 | 6 | 10.5 | 15.9 | 8.7 | 13.3 | 2.6 | 3.7 | 3.7 | 5.9 |

| SAE380/64/2 | 12 | 6 | 12.6 | 17.7 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE380/66/2 | 12 | 6 | 12.5 | 17.7 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE440/66/2 | 14 | 8 | 15.9 | 22.2 | 11 | 16.8 | 2.8 | 3.7 | 4.3 | 6.9 |

| SAE200/70/2 | 4 | 4 | 2.6 | 4.1 | 1.8 | 2.8 | 0.5 | 0.7 | 1.2 | 2 |

| SAE250/70/2 | 6 | 4 | 4.5 | 6.9 | 2.5 | 3.9 | 0.8 | 1.1 | 1.8 | 2.9 |

| SAE300/70/2 | 10 | 6 | 7.1 | 10.9 | 6.5 | 10 | 1.2 | 1.5 | 3.1 | 4.9 |

| SAE340/70/2 | 12 | 6 | 10.2 | 15.4 | 8.7 | 13.3 | 2.7 | 3.7 | 3.7 | 5.9 |

| SAE380/70/2 | 12 | 6 | 12.3 | 17.7 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE440/70/2 | 14 | 8 | 15.7 | 22.2 | 11 | 16.8 | 2.8 | 3.7 | 4.3 | 6.9 |

| SAEL300/72/2 | 8 | 4 | 7.5 | 11.2 | 4.6 | 7.1 | 1.3 | 1.8 | 2.5 | 3.9 |

| SAEL340/72/2 | 10 | 6 | 9.5 | 14.2 | 6.4 | 10 | 1.9 | 2.5 | 3.1 | 4.9 |

| SAE380/72/2 | 12 | 6 | 12.2 | 17.7 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE440/72/2 | 14 | 8 | 15.6 | 22.2 | 11 | 16.8 | 2.8 | 3.7 | 4.3 | 6.9 |

| SAE200/76/2 | 4 | 4 | 2.5 | 3.8 | 1.8 | 2.8 | 0.5 | 0.7 | 1.2 | 2 |

| SAE250/76/2 | 6 | 4 | 4.2 | 6.5 | 2.5 | 3.9 | 0.8 | 1.1 | 1.8 | 2.9 |

| SAEL300/76/2 | 8 | 4 | 7.3 | 10.9 | 4.6 | 7.1 | 1.3 | 1.8 | 2.5 | 3.9 |

| SAEL340/76/2 | 10 | 6 | 9.3 | 14 | 6.4 | 10 | 1.9 | 2.5 | 3.1 | 4.9 |

| SAE380/76/2 | 12 | 6 | 12 | 17.7 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE440/76/2 | 14 | 8 | 15.4 | 22.2 | 11 | 16.8 | 2.8 | 3.7 | 4.3 | 6.9 |

| SAE500/76/2 | 18 | 10 | 20.1 | 26.6 | 16.8 | 22.2 | 3.2 | 4.3 | 5.5 | 8.8 |

| SAE200/80/2 | 4 | 4 | 2.3 | 3.6 | 1.8 | 2.8 | 0.6 | 0.7 | 1.2 | 2 |

| SAE250/80/2 | 6 | 4 | 4.1 | 6.3 | 2.5 | 3.9 | 0.8 | 1.1 | 1.8 | 2.9 |

| SAEL300/80/2 | 8 | 4 | 7.1 | 10.7 | 4.6 | 7.1 | 1.4 | 1.8 | 2.5 | 3.9 |

| SAEL340/80/2 | 10 | 6 | 9.1 | 13.7 | 6.4 | 10 | 1.9 | 2.5 | 3.1 | 4.9 |

| SAE380/80/2 | 12 | 6 | 11.8 | 17.5 | 8.7 | 13.3 | 2.4 | 3.2 | 3.7 | 5.9 |

| SAE440/80/2 | 14 | 8 | 15.2 | 22.2 | 11 | 16.8 | 2.8 | 3.8 | 4.3 | 6.9 |

| SAE500/80/2 | 18 | 10 | 20.1 | 26.6 | 16.8 | 22.2 | 3.3 | 4.3 | 5.5 | 8.8 |

| SAE380/90/2 | 12 | 6 | 11.3 | 16.9 | 8.7 | 13.3 | 2.5 | 3.2 | 3.7 | 5.9 |

| SAE440/90/2 | 14 | 8 | 14.8 | 21.7 | 11 | 16.8 | 2.9 | 3.8 | 4.3 | 6.9 |

| SAE500/90/2 | 18 | 10 | 20.1 | 26.6 | 16.8 | 22.2 | 3.3 | 4.3 | 5.5 | 8.8 |

| SAE380/92/2 | 12 | 6 | 11.2 | 16.7 | 8.7 | 13.3 | 2.5 | 3.3 | 3.7 | 5.9 |

| SAE440/95/2 | 14 | 8 | 14.5 | 21.4 | 11 | 16.8 | 2.9 | 3.8 | 4.3 | 6.9 |

| SAE500/95/2 | 18 | 10 | 20.1 | 26.6 | 16.8 | 22.2 | 3.3 | 4.4 | 5.5 | 8.8 |

| SAEL300/100/2 | 8 | 4 | 6.2 | 9.5 | 4.6 | 7.1 | 1.4 | 1.8 | 2.5 | 3.9 |

| SAE380/100/2 | 12 | 6 | 10.8 | 16.2 | 8.7 | 13.3 | 2.5 | 3.3 | 3.7 | 5.9 |

| SAE440/100/2 | 14 | 8 | 14.2 | 21.1 | 11 | 16.8 | 2.9 | 3.8 | 4.3 | 6.9 |

| SAE500/100/2 | 18 | 10 | 20 | 26.6 | 16.8 | 22.2 | 3.3 | 4.4 | 5.5 | 8.8 |

| SAEL500/115/2 | 16 | 8 | 16.8 | 22.2 | 13.4 | 17.7 | 3.3 | 4.4 | 4.9 | 7.8 |

| SAEL380/120/2 | 10 | 6 | 9.1 | 13.7 | 6.4 | 10 | 1.6 | 2.2 | 3.1 | 4.9 |

| SAEL440/120/2 | 12 | 8 | 12.4 | 18.3 | 11.1 | 16.7 | 2 | 2.7 | 3.7 | 5.9 |

| SAEL500/120/2 | 16 | 8 | 16.8 | 22.2 | 13.4 | 17.7 | 3.3 | 4.4 | 4.9 | 7.8 |

| SAEL440/136/2 | 12 | 8 | 11.7 | 17.3 | 11.1 | 16.7 | 2.1 | 2.7 | 3.7 | 5.9 |

| SAEL500/140/2 | 16 | 8 | 16.1 | 22.2 | 13.4 | 17.7 | 3.3 | 4.4 | 4.9 | 7.8 |

| SAEL500/150/2 | 16 | 8 | 15.5 | 22.2 | 13.4 | 17.7 | 3.3 | 4.4 | 4.9 | 7.8 |

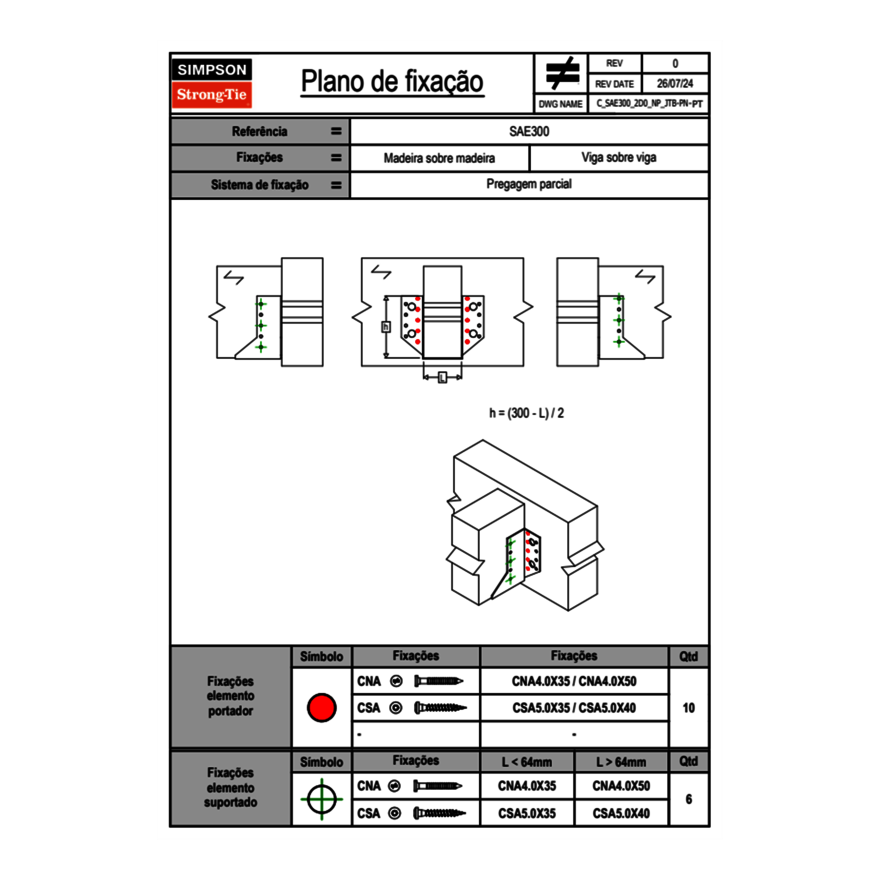

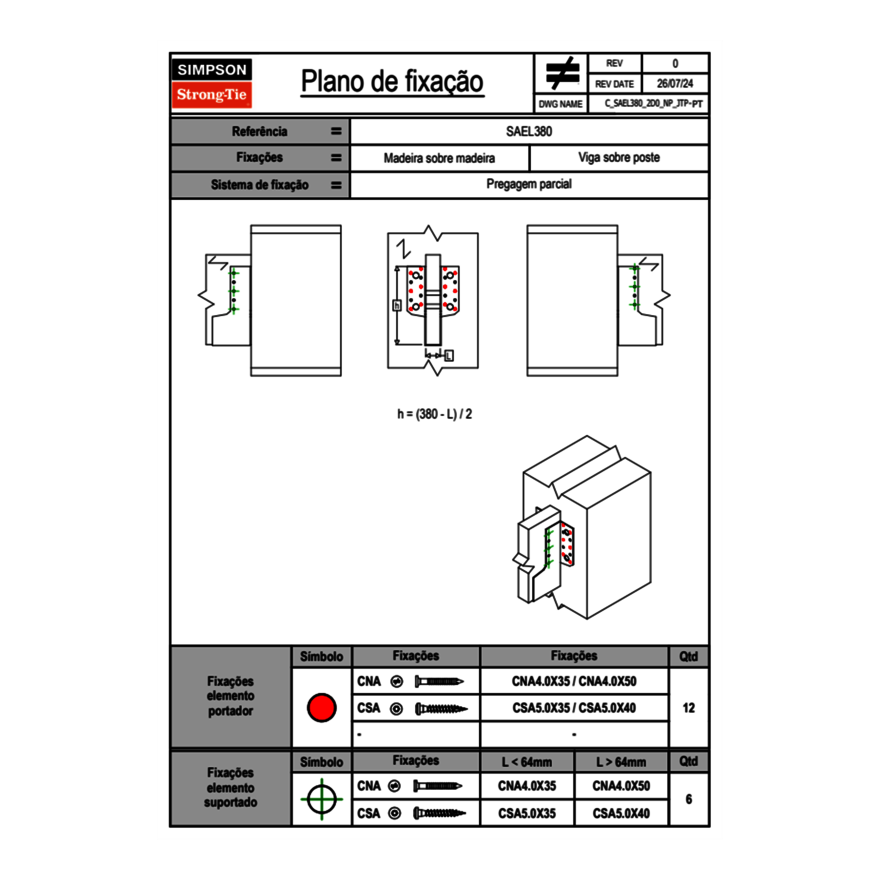

Os valores indicados na tabela acima são válidos para vigota sobre viga e vigota sobre pilar, desde que respeitados os planos de cravação parcial específicos para cada configuração dada em nossa ETE-06/0270 página 17.

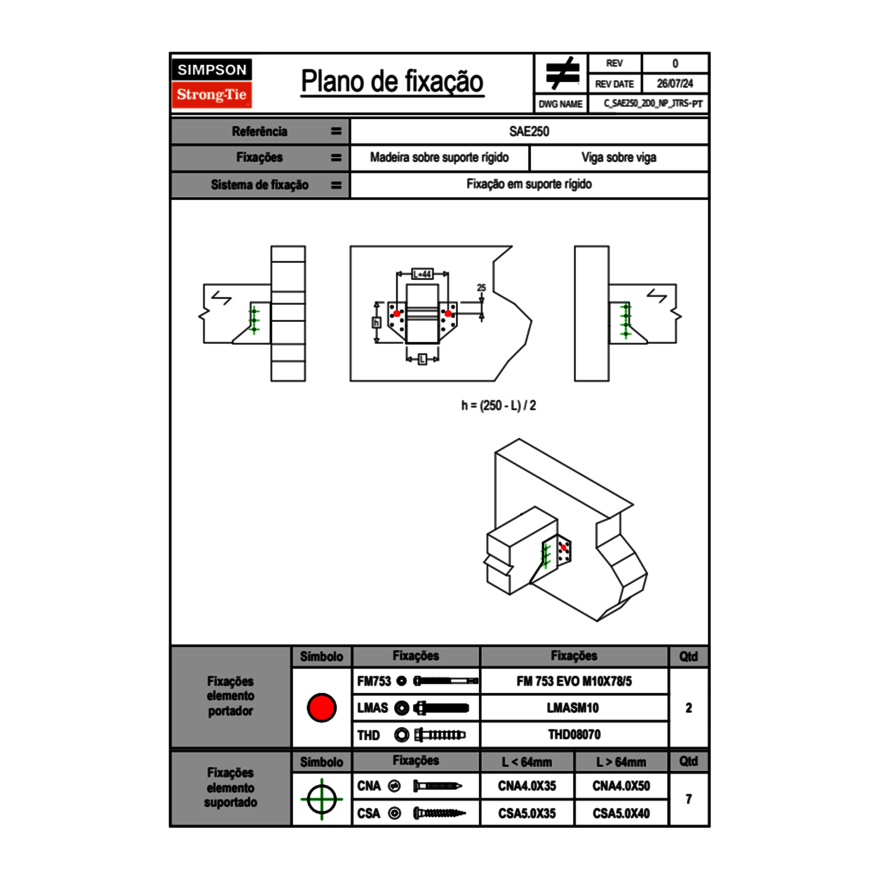

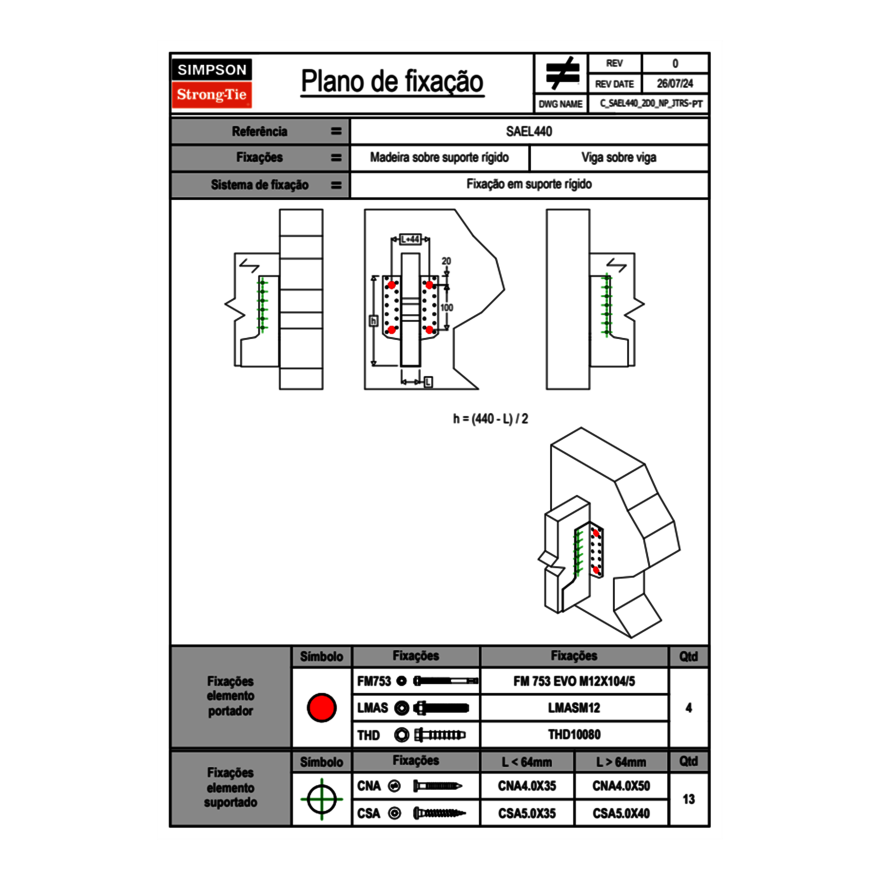

Valores caraterísticos Descendente (em kN) – Elemento rígido – Perno WA

| Referência | Valores característicos - Madeira sobre betão ou aço | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixacões | Valores característicos - Madeira classe C24 [kN] | |||||||||||

| Portador | Suportado | R1.k | R2.k | R3.k | R4.k | |||||||

| Qdad | Tipo | Qdad | Tipo | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | CNA4,0x35 | CNA4,0x50 | |

| SAE200/32/2 | 2 | Ø10* | 5 | CNA** | 11.7 | - | 8.4 | - | 2.1 | - | 5 | - |

| SAE250/32/2 | 2 | Ø10* | 7 | CNA** | 15.1 | - | 11.7 | - | 2.8 | - | 5 | - |

| SAE300/32/2 | 4 | Ø12* | 10 | CNA** | 20.1 | - | 16.8 | - | 3.6 | - | 10 | - |

| SAE200/38/2 | 2 | Ø10* | 5 | CNA** | 11.7 | - | 8.4 | - | 2.2 | - | 5 | - |

| SAE250/38/2 | 2 | Ø10* | 7 | CNA** | 15.1 | - | 11.7 | - | 3 | - | 5 | - |

| SAE300/38/2 | 4 | Ø12* | 10 | CNA** | 20.1 | - | 16.8 | - | 4 | - | 10 | - |

| SAE340/38/2 | 4 | Ø12* | 12 | CNA** | 23.5 | - | 20.1 | - | 4.5 | - | 10 | - |

| SAE440/38/2 | 4 | Ø12* | 15 | CNA** | 28.5 | - | 25.1 | - | 5 | - | 10 | - |

| SAE200/40/2 | 2 | Ø10* | 5 | CNA** | 11.7 | - | 8.4 | - | 2.3 | - | 5 | - |

| SAE250/40/2 | 2 | Ø10* | 7 | CNA** | 15.1 | - | 11.7 | - | 3.1 | - | 5 | - |

| SAE300/40/2 | 4 | Ø12* | 10 | CNA** | 20.1 | - | 16.8 | - | 4.1 | - | 10 | - |

| SAE340/40/2 | 4 | Ø12* | 12 | CNA** | 23.5 | - | 20.1 | - | 4.6 | - | 10 | - |

| SAE200/46/2 | 2 | Ø10* | 5 | CNA** | 11.7 | - | 8.4 | - | 2.4 | - | 5 | - |

| SAE250/46/2 | 2 | Ø10* | 7 | CNA** | 15.1 | - | 11.7 | - | 3.3 | - | 5 | - |

| SAE340/46/2 | 4 | Ø12* | 12 | CNA** | 23.5 | - | 20.1 | - | 5 | - | 10 | - |

| SAE500/46/2 | 4 | Ø12* | 18 | CNA** | 33.5 | - | 30.2 | - | 6.2 | - | 10 | - |

| SAE200/50/2 | 2 | Ø10* | 5 | CNA** | 11.7 | - | 8.4 | - | 2.5 | - | 5 | - |

| SAE250/50/2 | 2 | Ø10* | 7 | CNA** | 15.1 | - | 11.7 | - | 3.4 | - | 5 | - |

| SAE300/50/2 | 4 | Ø12* | 10 | CNA** | 20.1 | - | 16.8 | - | 4.6 | - | 10 | - |

| SAE340/50/2 | 4 | Ø12* | 12 | CNA** | 23.5 | - | 20.1 | - | 5.2 | - | 10 | - |

| SAE500/50/2 | 4 | Ø12* | 18 | CNA** | 33.5 | - | 30.2 | - | 6.6 | - | 10 | - |

| SAE200/60/2 | 2 | Ø10* | 5 | CNA** | 11.7 | 15.5 | 8.4 | 11.1 | 2.6 | 4 | 5 | 5 |

| SAE250/60/2 | 2 | Ø10* | 7 | CNA** | 15.1 | 19 | 11.7 | 15.5 | 3.6 | 5.4 | 5 | 5 |

| SAE300/60/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 4.9 | 7.3 | 10 | 10 |

| SAE340/60/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 5.7 | 8.3 | 10 | 10 |

| SAE200/64/2 | 2 | Ø10* | 5 | CNA** | 11.7 | 15.5 | 8.4 | 11.1 | 2.7 | 4.1 | 5 | 5 |

| SAE250/64/2 | 2 | Ø10* | 7 | CNA** | 15.1 | 19 | 11.7 | 15.5 | 3.7 | 5.6 | 5 | 5 |

| SAE300/64/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5 | 7.5 | 10 | 10 |

| SAE340/64/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 5.8 | 8.6 | 10 | 10 |

| SAE380/64/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 5.8 | 8.6 | 10 | 10 |

| SAE380/66/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 5.9 | 8.7 | 10 | 10 |

| SAE440/66/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 6.9 | 10.1 | 10 | 10 |

| SAE200/70/2 | 2 | Ø10* | 5 | CNA** | 11.7 | 15.5 | 8.4 | 11.1 | 2.7 | 4.2 | 5 | 5 |

| SAE250/70/2 | 2 | Ø10* | 7 | CNA** | 15.1 | 19 | 11.7 | 15.5 | 3.8 | 5.7 | 5 | 5 |

| SAE300/70/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5.2 | 7.8 | 10 | 10 |

| SAE340/70/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6 | 8.9 | 10 | 10 |

| SAE380/70/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6 | 8.9 | 10 | 10 |

| SAE440/70/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.1 | 10.4 | 10 | 10 |

| SAEL300/72/2 | 4 | Ø12* | 8 | CNA** | 16.8 | 22.2 | 13.4 | 17.7 | 4.2 | 6.4 | 10 | 10 |

| SAEL340/72/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5.1 | 7.7 | 10 | 10 |

| SAE380/72/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.1 | 9 | 10 | 10 |

| SAE440/72/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.1 | 10.5 | 10 | 10 |

| SAE200/76/2 | 2 | Ø10* | 5 | CNA** | 11.7 | 15.5 | 8.4 | 11.1 | 2.8 | 4.3 | 5 | 5 |

| SAE250/76/2 | 2 | Ø10* | 7 | CNA** | 15.1 | 19 | 11.7 | 15.5 | 3.8 | 5.9 | 5 | 5 |

| SAEL300/76/2 | 4 | Ø12* | 8 | CNA** | 16.8 | 22.2 | 13.4 | 17.7 | 4.3 | 6.5 | 10 | 10 |

| SAEL340/76/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5.2 | 7.8 | 10 | 10 |

| SAE380/76/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.2 | 9.2 | 10 | 10 |

| SAE440/76/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.3 | 10.8 | 10 | 10 |

| SAE500/76/2 | 4 | Ø12* | 18 | CNA** | 33.5 | 38 | 30.2 | 37.6 | 8.2 | 12 | 10 | 10 |

| SAE200/80/2 | 2 | Ø10* | 5 | CNA** | 11.7 | 15.5 | 8.4 | 11.1 | 2.8 | 4.3 | 5 | 5 |

| SAE250/80/2 | 2 | Ø10* | 7 | CNA** | 15.1 | 19 | 11.7 | 15.5 | 3.9 | 5.9 | 5 | 5 |

| SAEL300/80/2 | 4 | Ø12* | 8 | CNA** | 16.8 | 22.2 | 13.4 | 17.7 | 4.3 | 6.6 | 10 | 10 |

| SAEL340/80/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5.3 | 8 | 10 | 10 |

| SAE380/80/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.2 | 9.4 | 10 | 10 |

| SAE440/80/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.4 | 11 | 10 | 10 |

| SAE500/80/2 | 4 | Ø12* | 18 | CNA** | 33.5 | 38 | 30.2 | 37.7 | 8.4 | 12.3 | 10 | 10 |

| SAE380/90/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.4 | 9.8 | 10 | 10 |

| SAE440/90/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.7 | 11.6 | 10 | 10 |

| SAE500/90/2 | 4 | Ø12* | 18 | CNA** | 33.5 | 38 | 30.2 | 37.7 | 8.8 | 13.1 | 10 | 10 |

| SAE380/92/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.5 | 9.8 | 10 | 10 |

| SAE440/95/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.8 | 11.8 | 10 | 10 |

| SAE500/95/2 | 4 | Ø12* | 18 | CNA** | 33.5 | 38 | 30.2 | 37.7 | 9 | 13.4 | 10 | 10 |

| SAEL300/100/2 | 4 | Ø12* | 8 | CNA** | 16.8 | 22.2 | 13.4 | 17.7 | 4.5 | 7 | 10 | 10 |

| SAE380/100/2 | 4 | Ø12* | 12 | CNA** | 23.5 | 31 | 20.1 | 26.6 | 6.6 | 10.1 | 10 | 10 |

| SAE440/100/2 | 4 | Ø12* | 15 | CNA** | 28.5 | 37.7 | 25.1 | 33.2 | 7.9 | 12 | 10 | 10 |

| SAE500/100/2 | 4 | Ø12* | 18 | CNA** | 33.5 | 38 | 30.2 | 37.7 | 9.1 | 13.7 | 10 | 10 |

| SAEL500/115/2 | 4 | Ø12* | 16 | CNA** | 30.2 | 38 | 26.8 | 35.5 | 8.6 | 13 | 10 | 10 |

| SAEL380/120/2 | 4 | Ø12* | 10 | CNA** | 20.1 | 26.6 | 16.8 | 22.2 | 5.7 | 8.9 | 10 | 10 |

| SAEL440/120/2 | 4 | Ø12* | 13 | CNA** | 25.1 | 33.2 | 21.8 | 28.8 | 7.2 | 11.1 | 10 | 10 |

| SAEL500/120/2 | 4 | Ø12* | 16 | CNA** | 30.2 | 38 | 26.8 | 35.5 | 8.6 | 13.2 | 10 | 10 |

| SAEL440/136/2 | 4 | Ø12* | 13 | CNA** | 25.1 | 33.2 | 21.8 | 28.8 | 7.4 | 11.4 | 10 | 10 |

| SAEL500/140/2 | 4 | Ø12* | 16 | CNA** | 30.2 | 38 | 26.8 | 35.5 | 8.9 | 13.7 | 10 | 10 |

| SAEL500/150/2 | 4 | Ø12* | 16 | CNA** | 30.2 | 38 | 26.8 | 35.5 | 9 | 13.9 | 10 | 10 |

* Refer to the Simpson Strong-Tie anchor product range for suitable anchors. Typical anchor solutions depend on the concrete type, spacing and edge distances. The values in this table are given for an installation in the middle of a concrete slab. In other installation condition (close to the edge,...), the designer must check the anchor separately (Our free software Anchor Designer is available for download on our website).

** Refer to Characteristic Capacity table columns for type of fasteners that can be used in Flange A. Capacities vary depending on fastener type used.

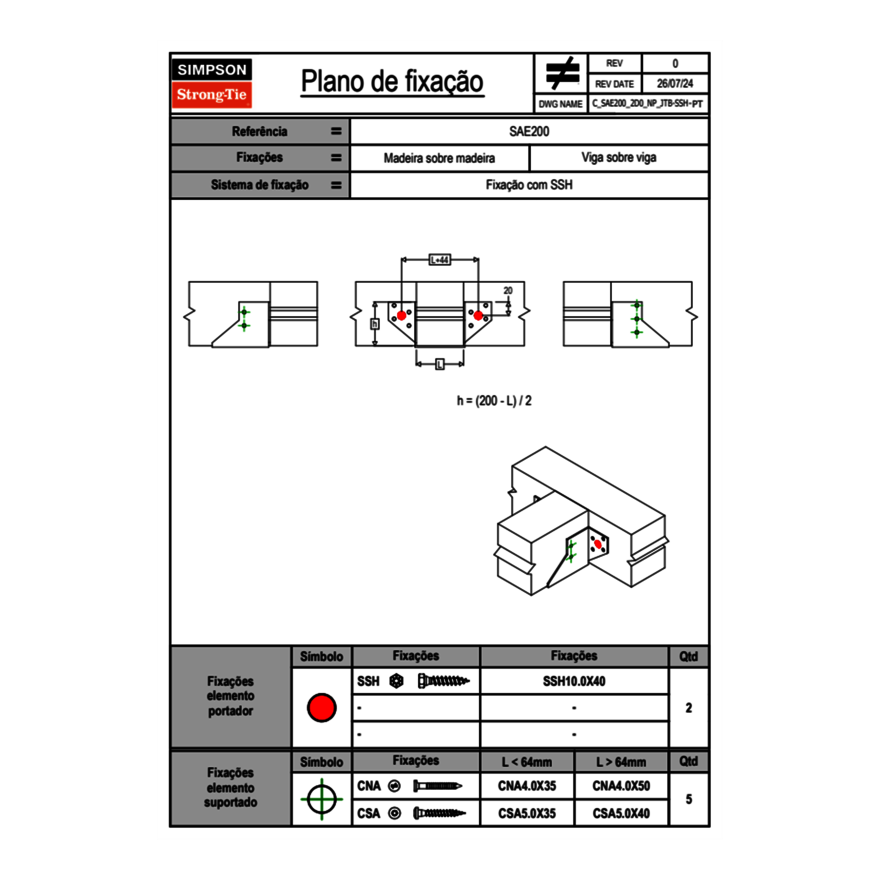

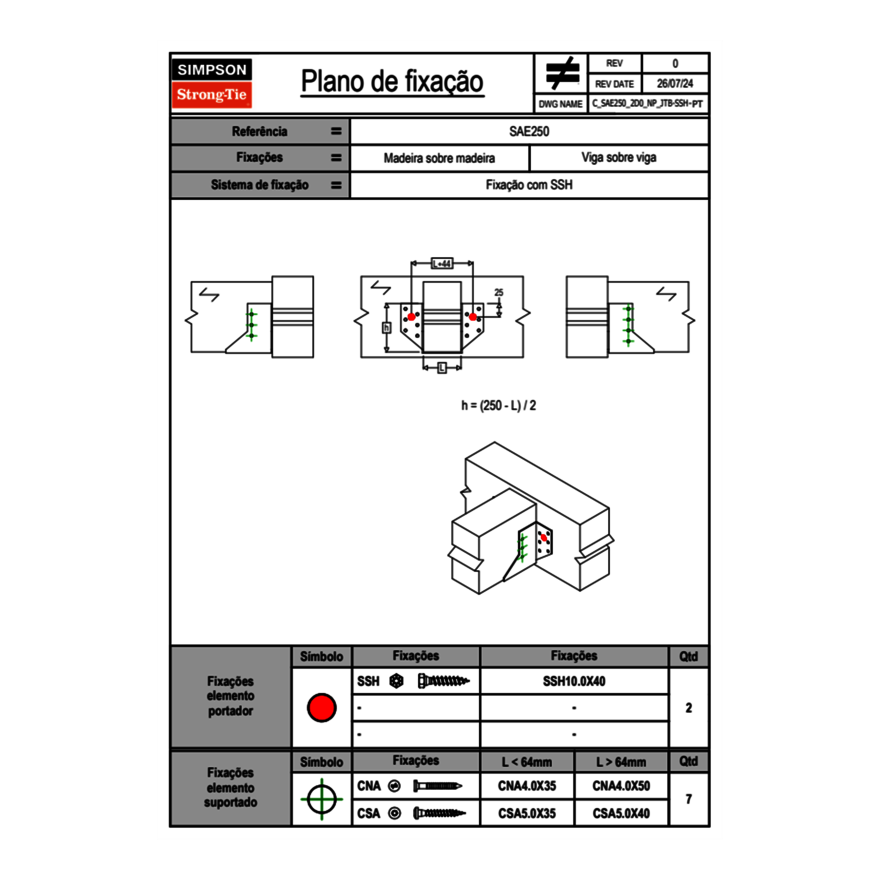

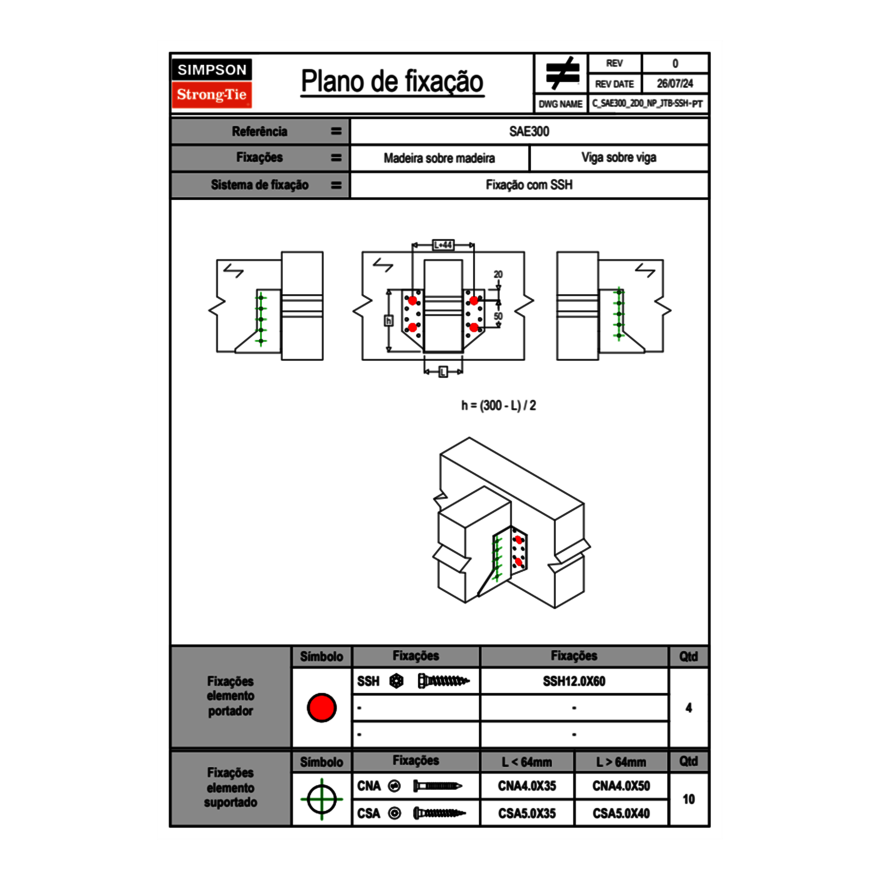

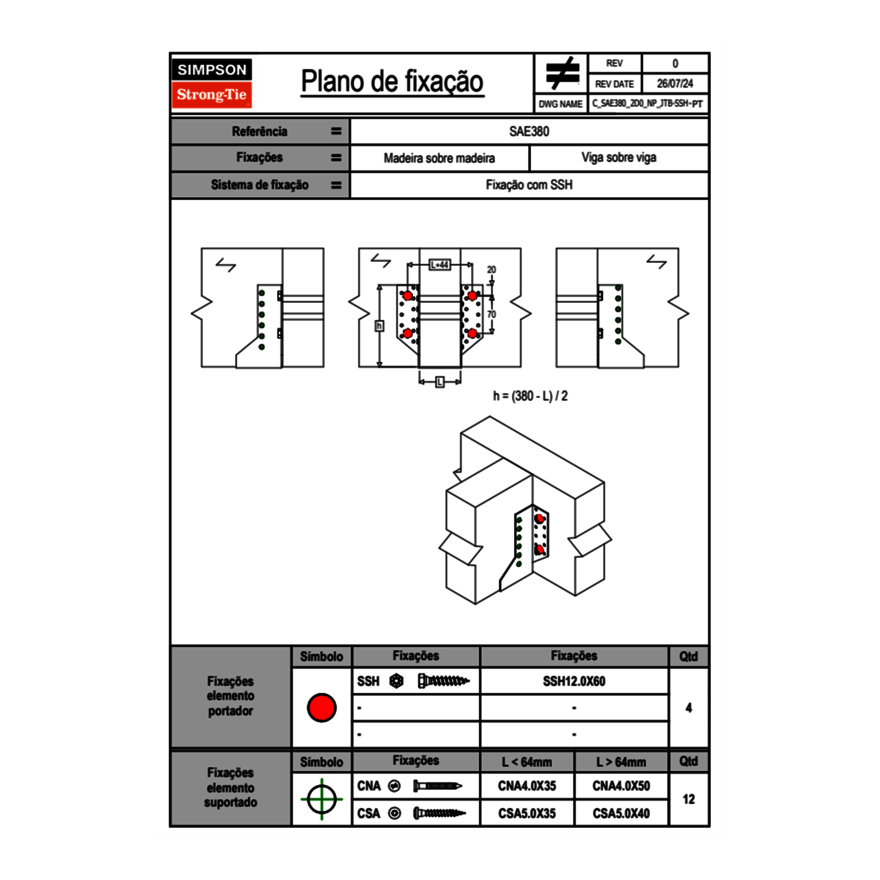

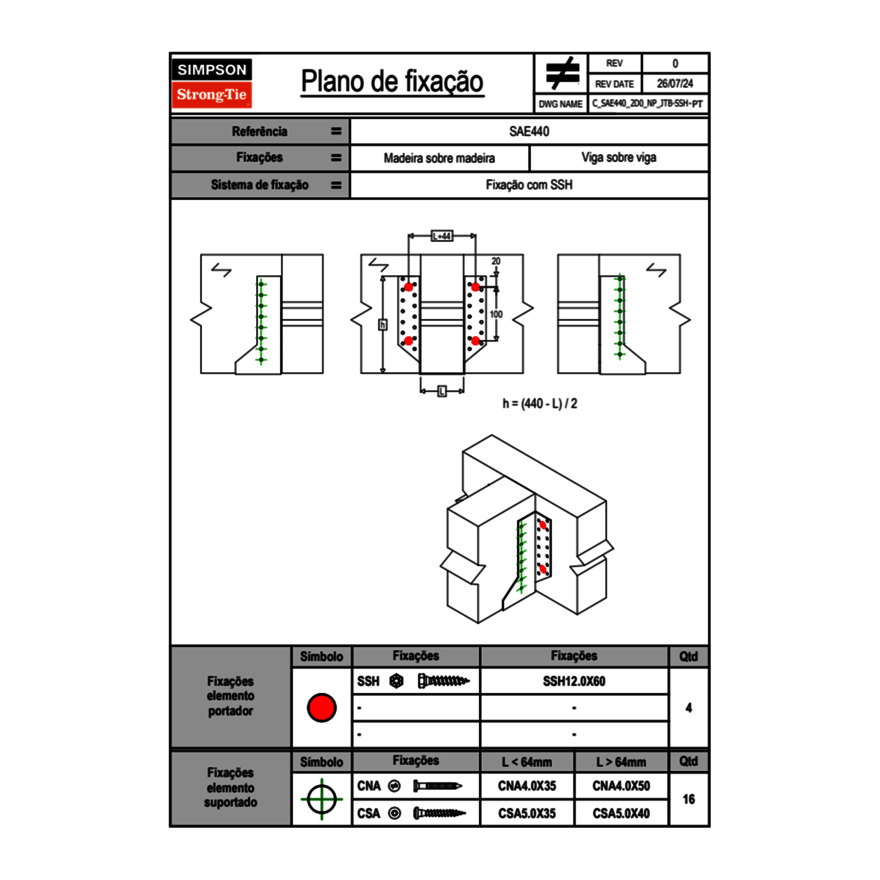

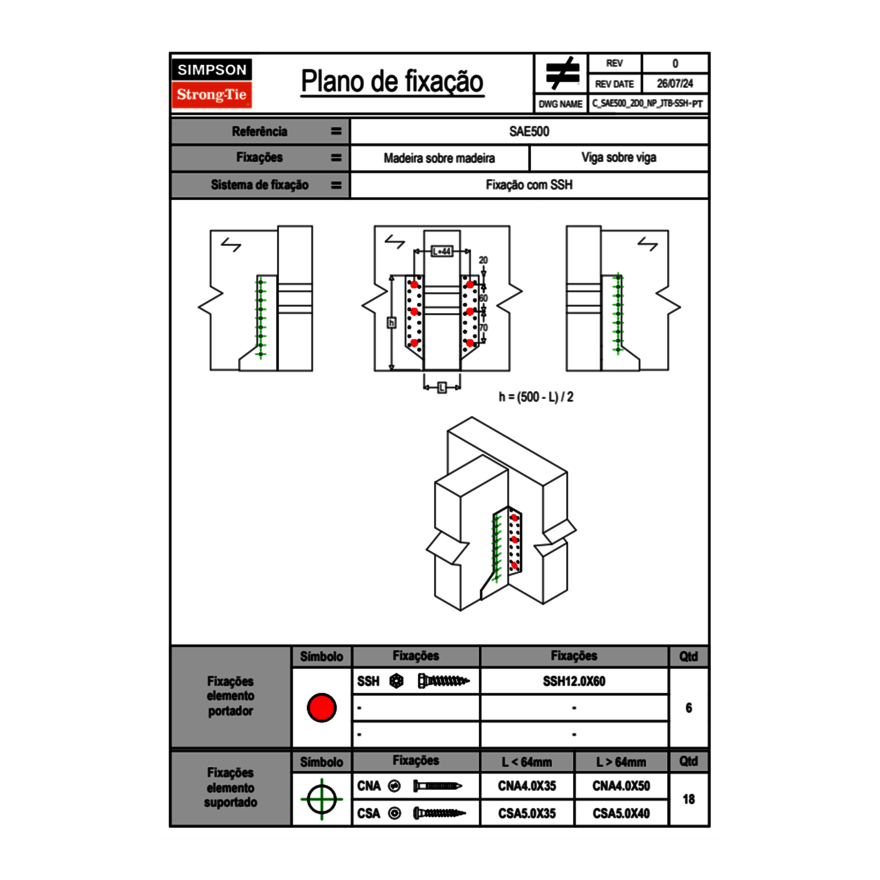

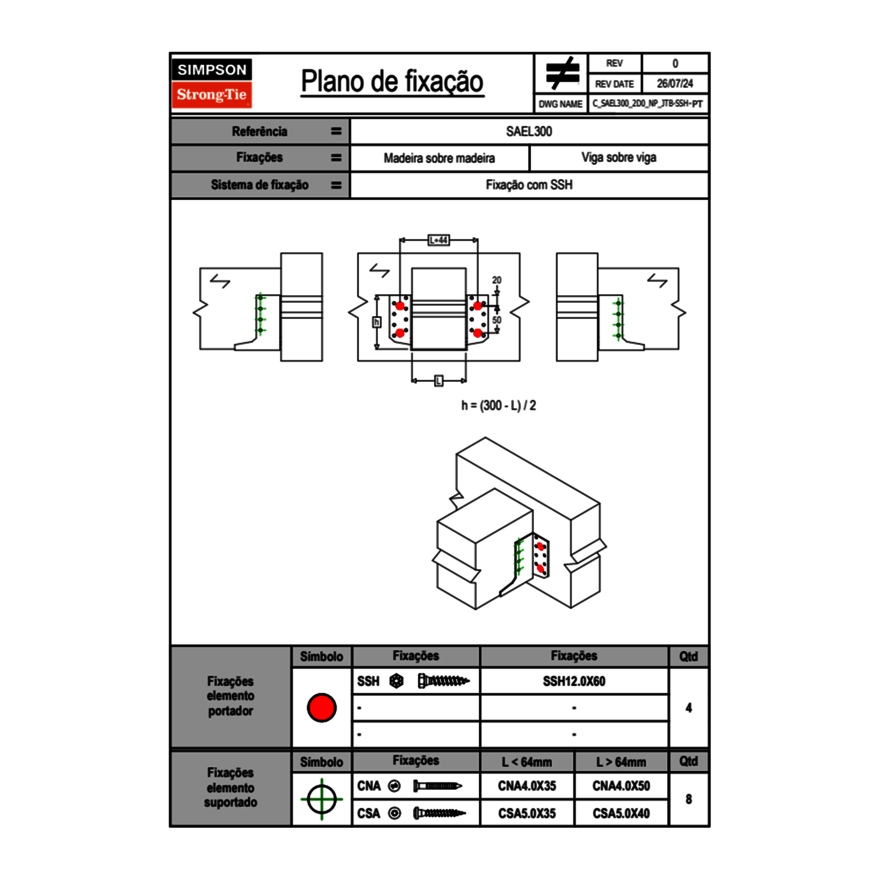

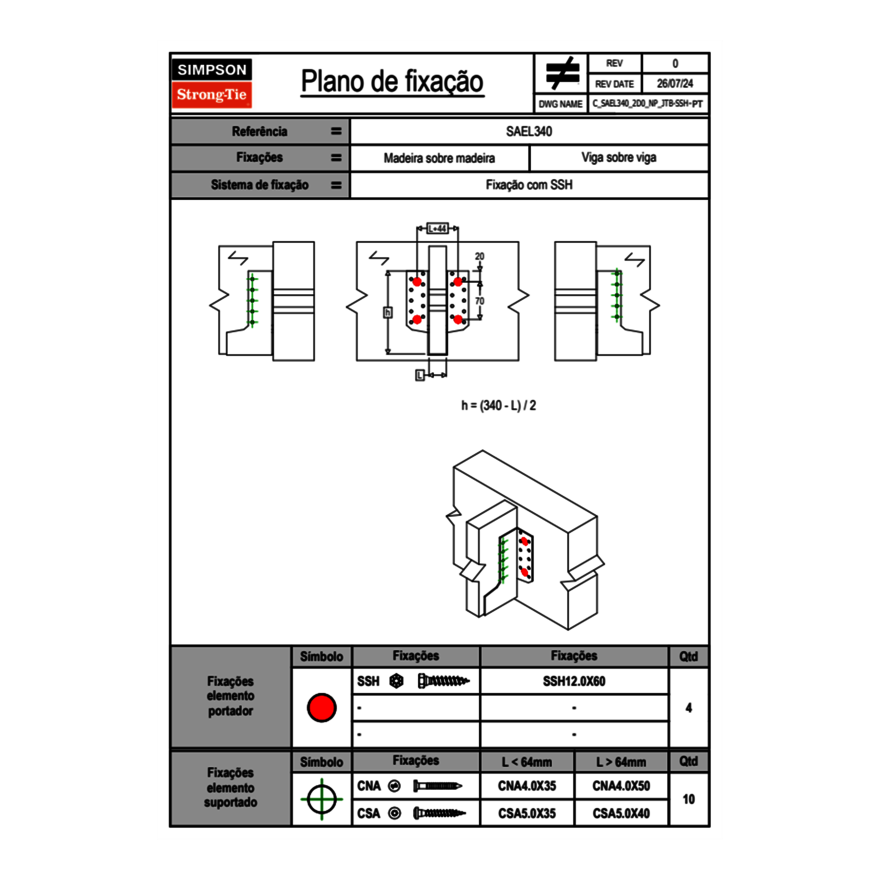

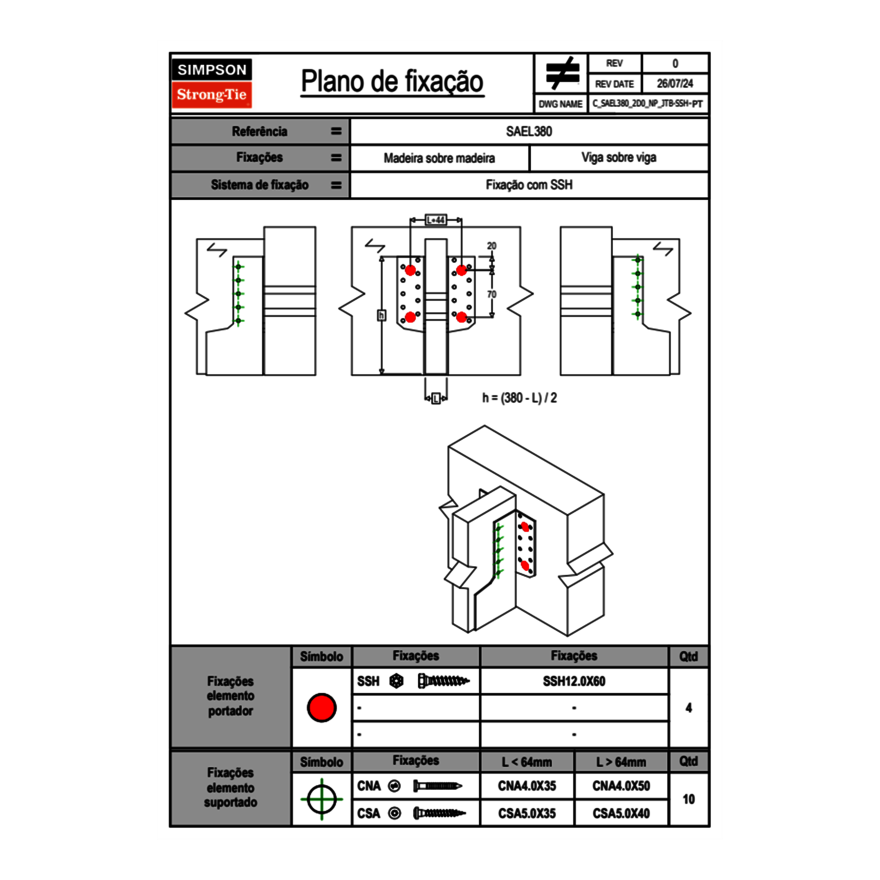

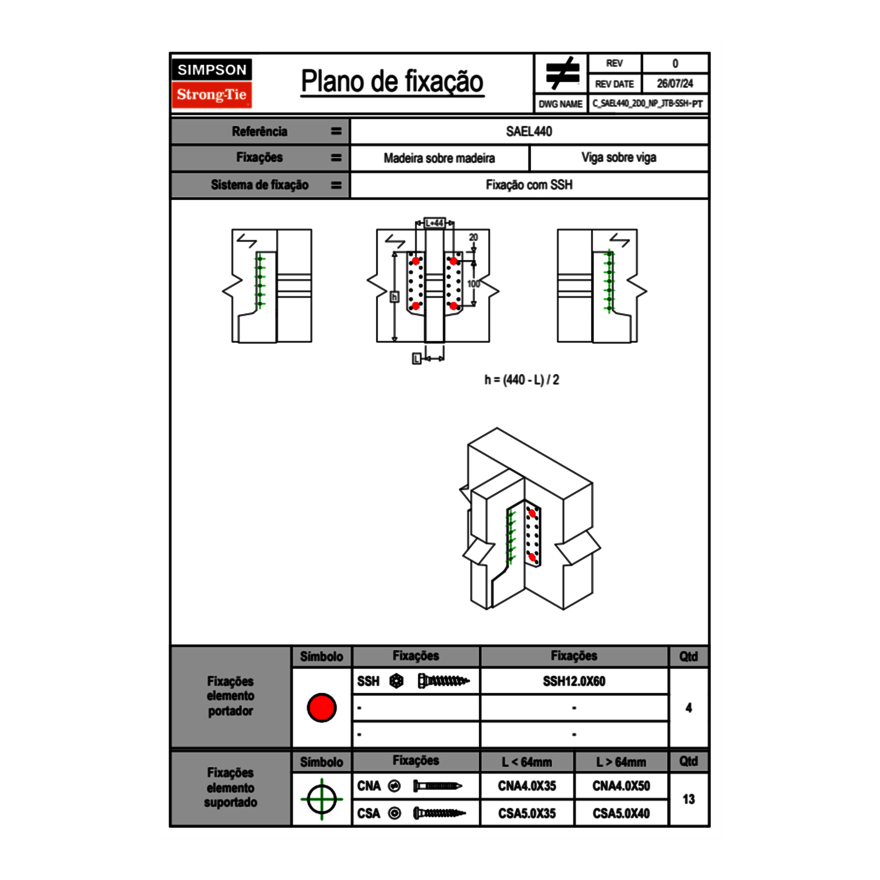

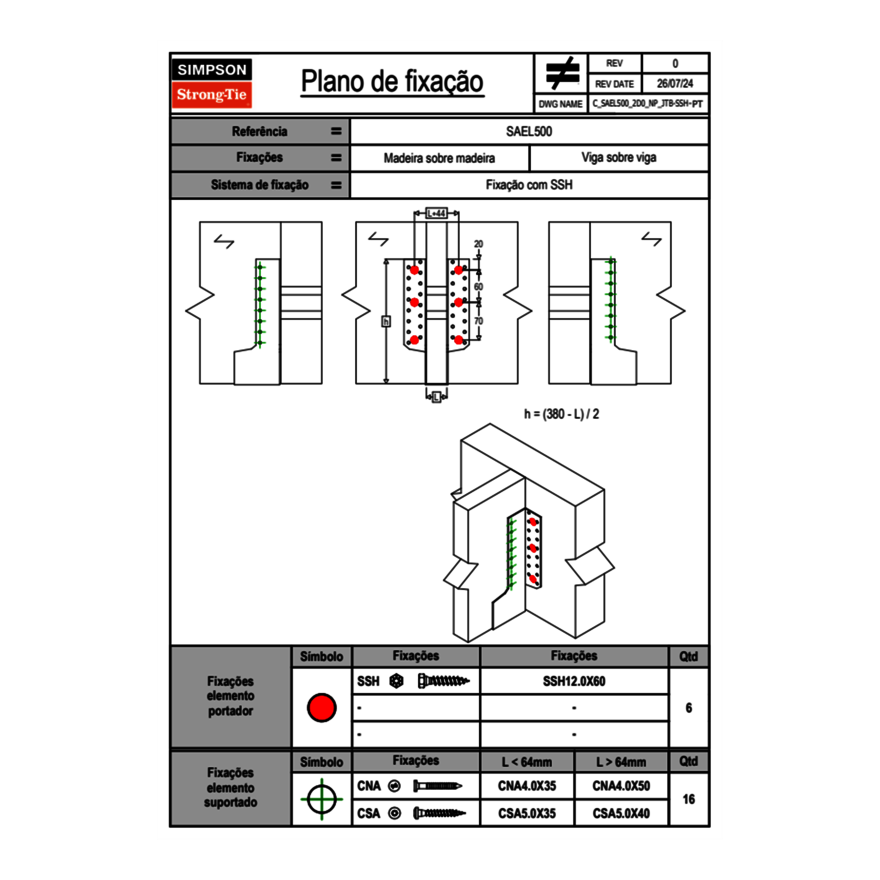

Valores caraterísticos - Madeira/Madeira - com parafuso SSH para conexões

| Referência |

Valores caracteristicos - Madeira/madeira - com parafuso SSH para conexões | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fixacões | Valores caracteristicos - Madeira C24 [kN] | |||||||||||

| Portador | Suportado | R1.k | R2.k | R3.k | R4.k | |||||||

| Qdad | Tipo | Qdad | Tipo | CNA4.0x35 | CNA4.0x50 | CNA4.0x35 | CNA4.0x50 | CNA4.0x35 | CNA4.0x50 | CNA4.0x35 | CNA4.0x50 | |

| SAE200/2X | 2 | SSH10.0x40 | 5 | CNA* | 5.6 | 6.3 | 5.7 | 6.4 | 2.1 | 3.6 | 5 | 5 |

| SAE250/2X | 2 | SSH10.0x40 | 7 | CNA* | 7 | 7.2 | 6.9 | 7.2 | 2 | 2.7 | 5 | 5 |

| SAE300 | 2 | SSH12.0x60 | 10 | CNA* | 11.4 | 11.5 | 11.4 | 11.5 | 3.4 | 4.1 | 5 | 5 |

| SAEL300/2X | 2 | SSH12.0x60 | 8 | CNA* | 10.7 | 11.4 | 10.8 | 11.4 | 3 | 4.1 | 5 | 5 |

| SAE340 | 4 | SSH12.0x60 | 12 | CNA* | 18.4 | 21 | 18.4 | 21 | 3.8 | 6.4 | 10 | 10 |

| SAEL340/2X | 4 | SSH12.0x60 | 10 | CNA* | 15.3 | 19.1 | 15.3 | 19.7 | 3.4 | 6.2 | 10 | 10 |

| SAE380 | 4 | SSH12.0x60 | 12 | CNA* | 18.4 | 21 | 18.4 | 21 | 3.8 | 5.6 | 10 | 10 |

| SAEL380/2X | 4 | SSH12.0x60 | 10 | CNA* | 15.3 | 19.1 | 15.3 | 19.7 | 3.4 | 5.6 | 10 | 10 |

| SAE440 | 4 | SSH12.0x60 | 15 | CNA* | 22 | 23 | 22 | 23 | 4.2 | 5.3 | 10 | 10 |

| SAEL440/2X | 4 | SSH12.0x60 | 13 | CNA* | 19.9 | 22.7 | 20 | 22.8 | 4 | 5.3 | 10 | 10 |

| SAE500 | 6 | SSH12.0x60 | 18 | CNA* | 27.7 | 33.4 | 27.7 | 33.4 | 4.5 | 6.5 | 15 | 15 |

| SAEL500/2X | 6 | SSH12.0x60 | 16 | CNA* | 24.6 | 31.7 | 24.6 | 32.2 | 4.3 | 6.5 | 15 | 15 |

A tensão transversal deve ser verificada pelo utilizador e pode reger.

A espessura mínima da viga principal para a utilização de um parafuso SSH Ø10x40 é de 38 mm e para SSH Ø12x60 é de 73 mm

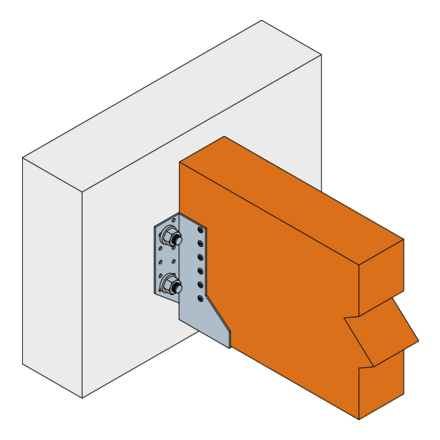

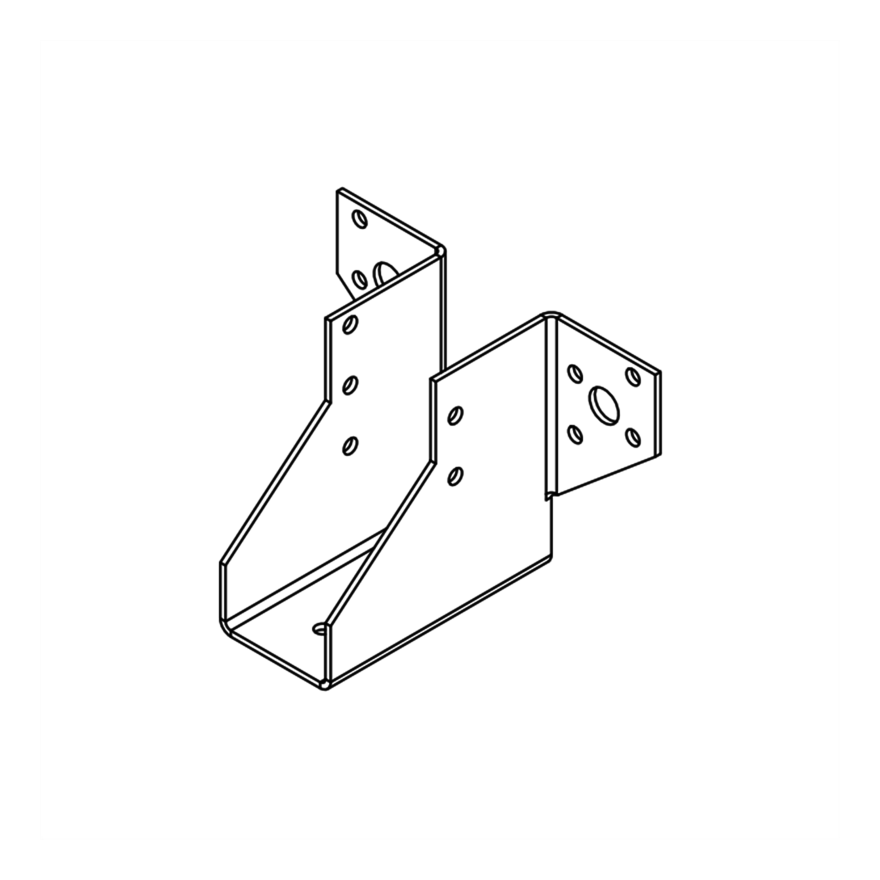

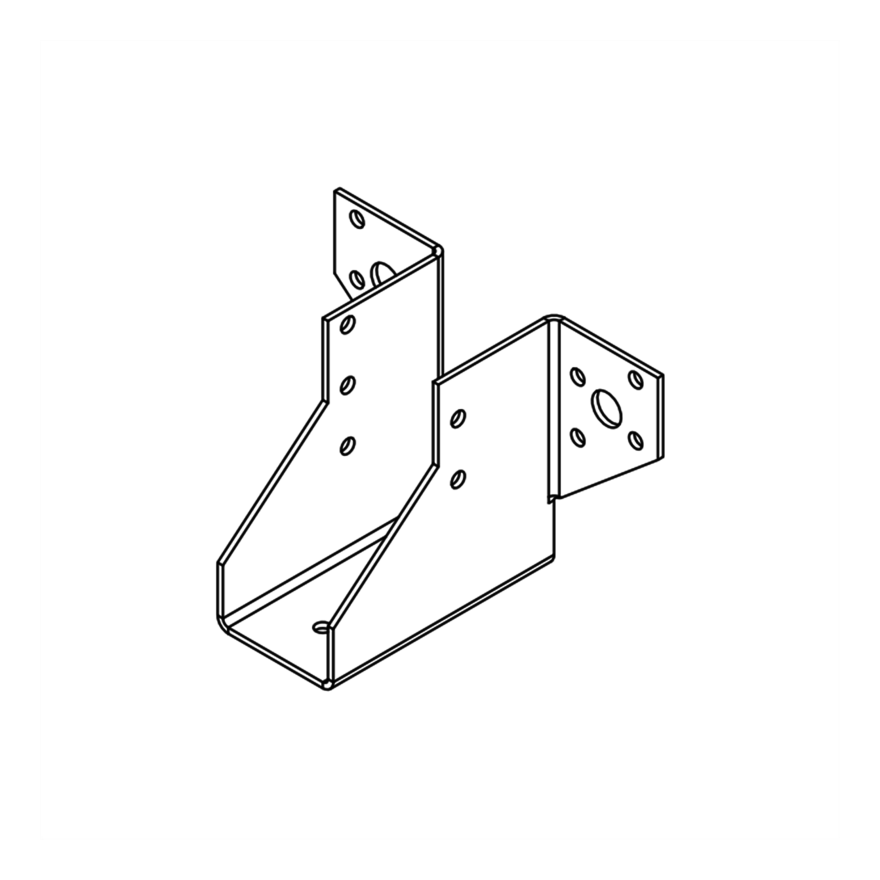

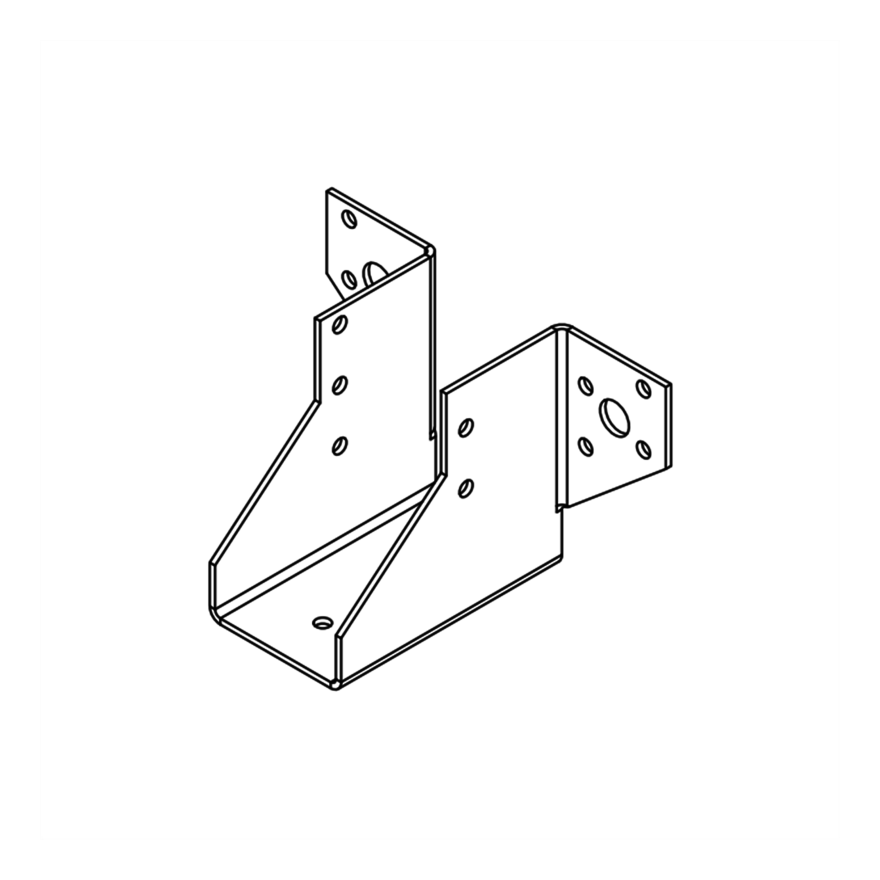

Instalação

Instalação

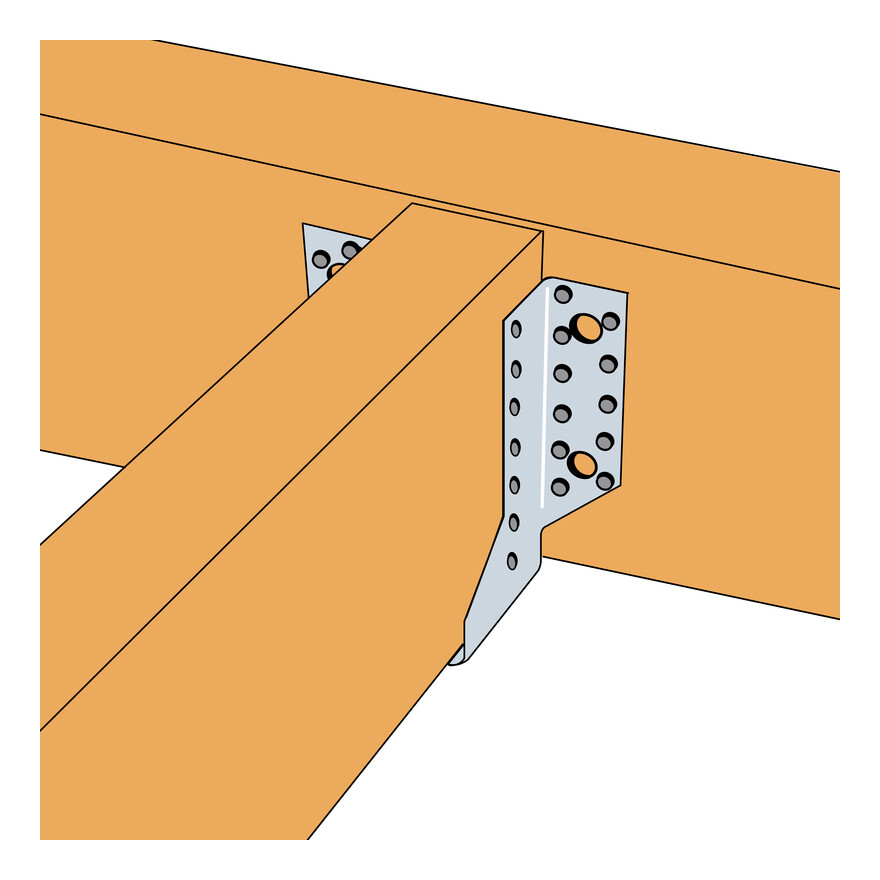

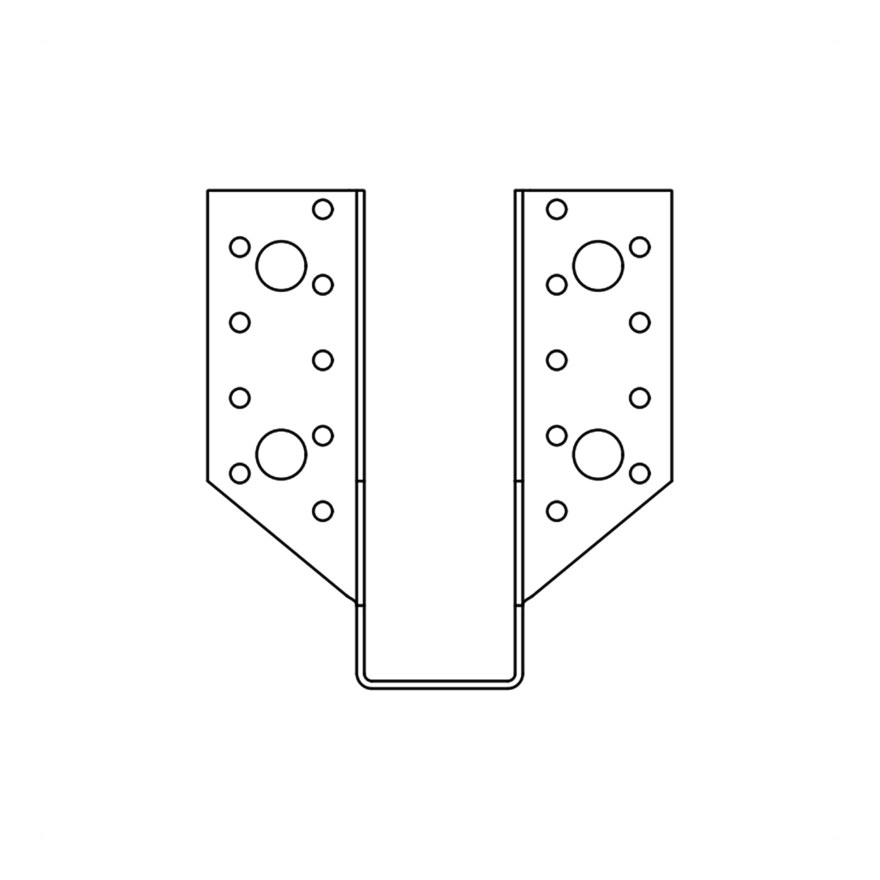

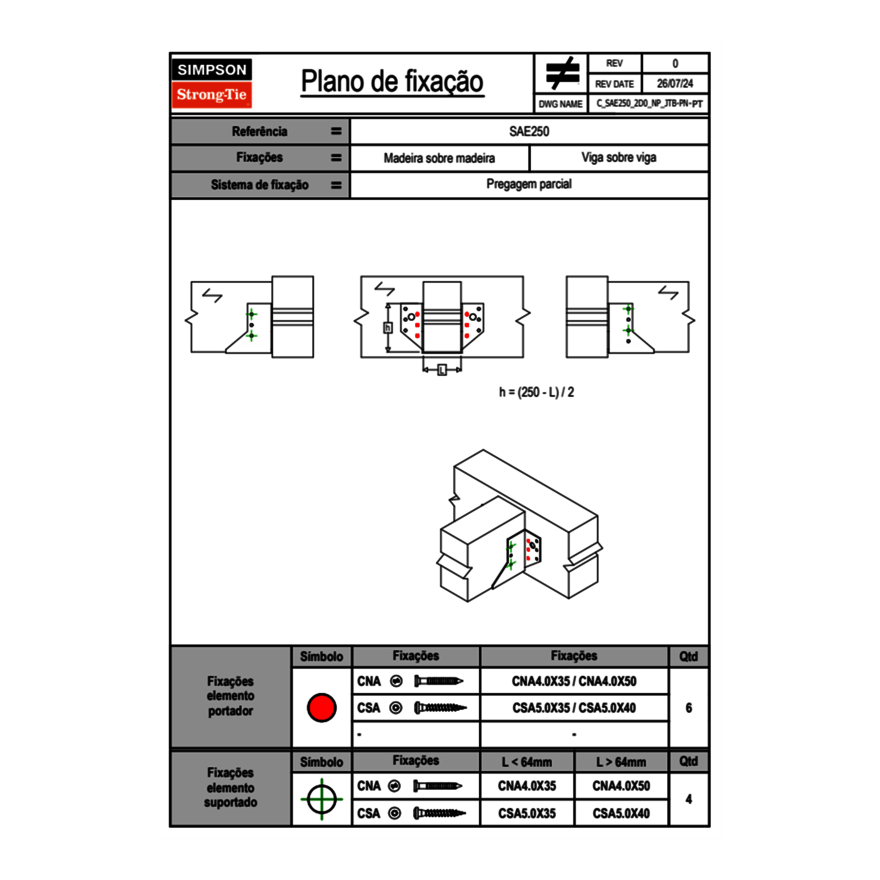

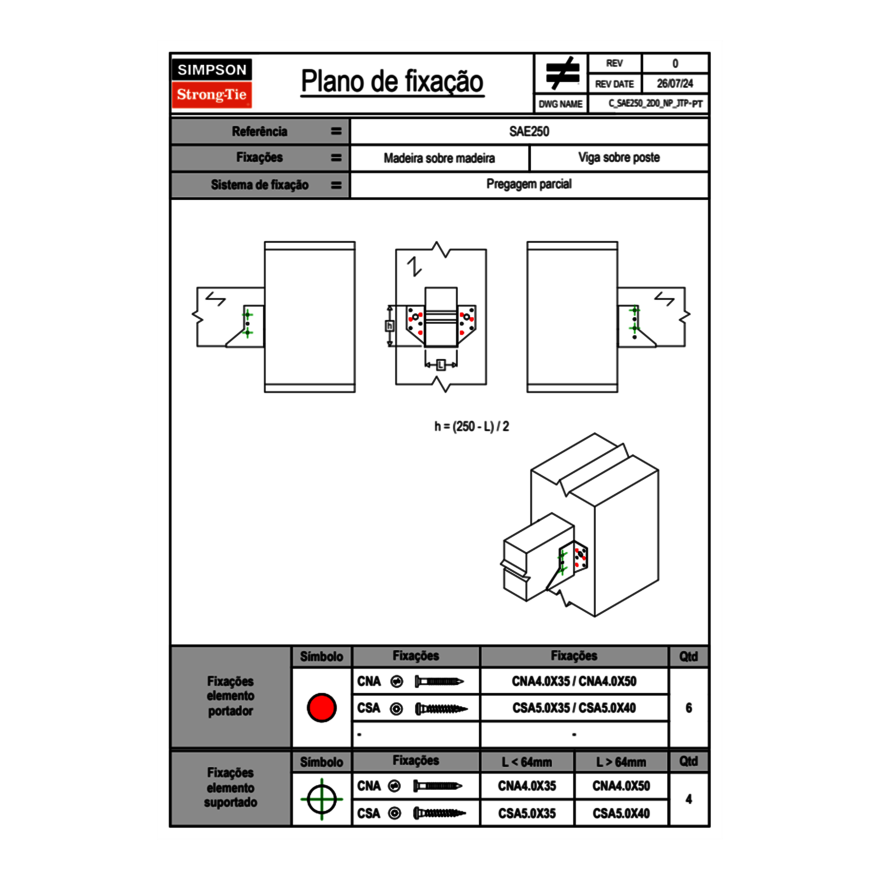

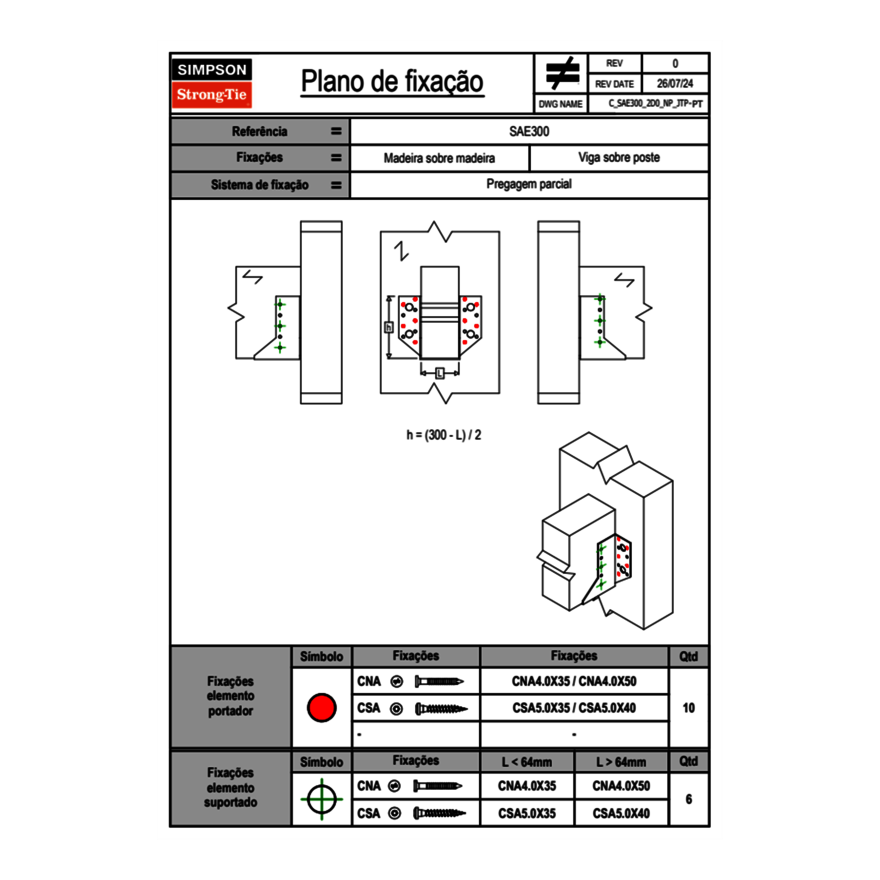

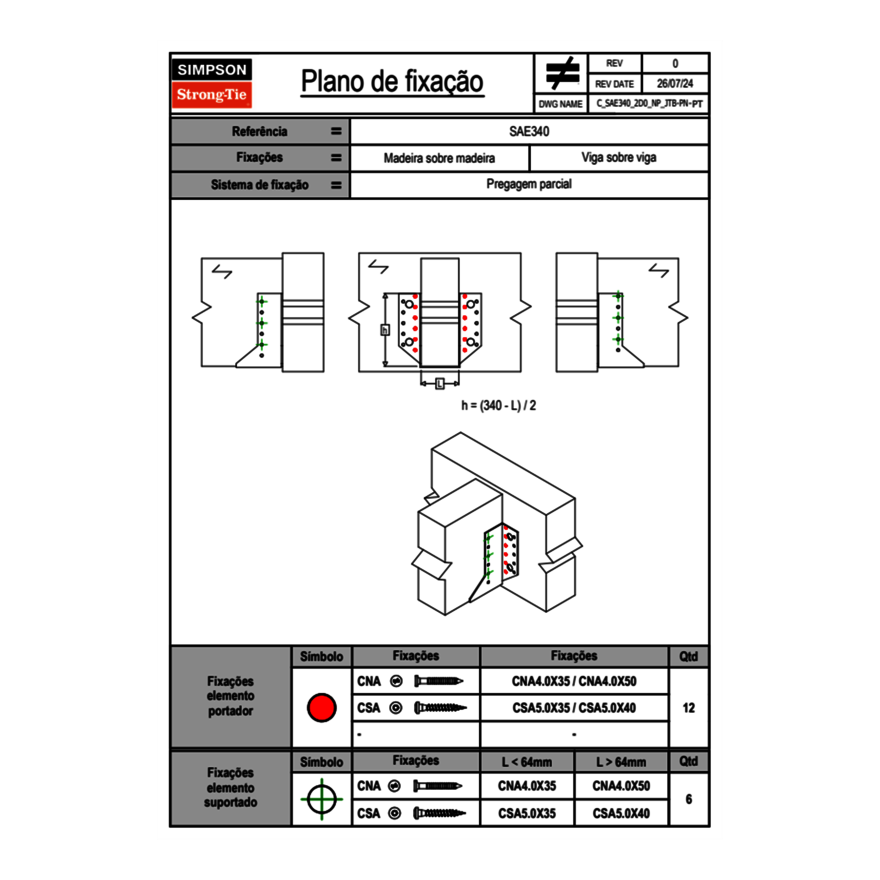

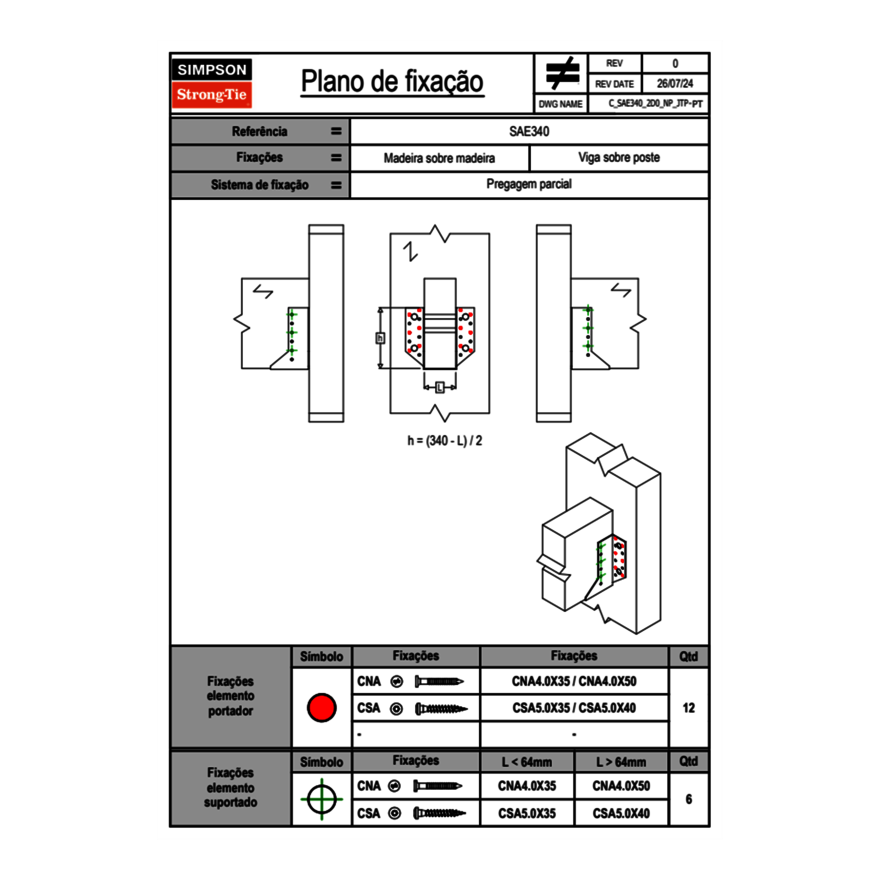

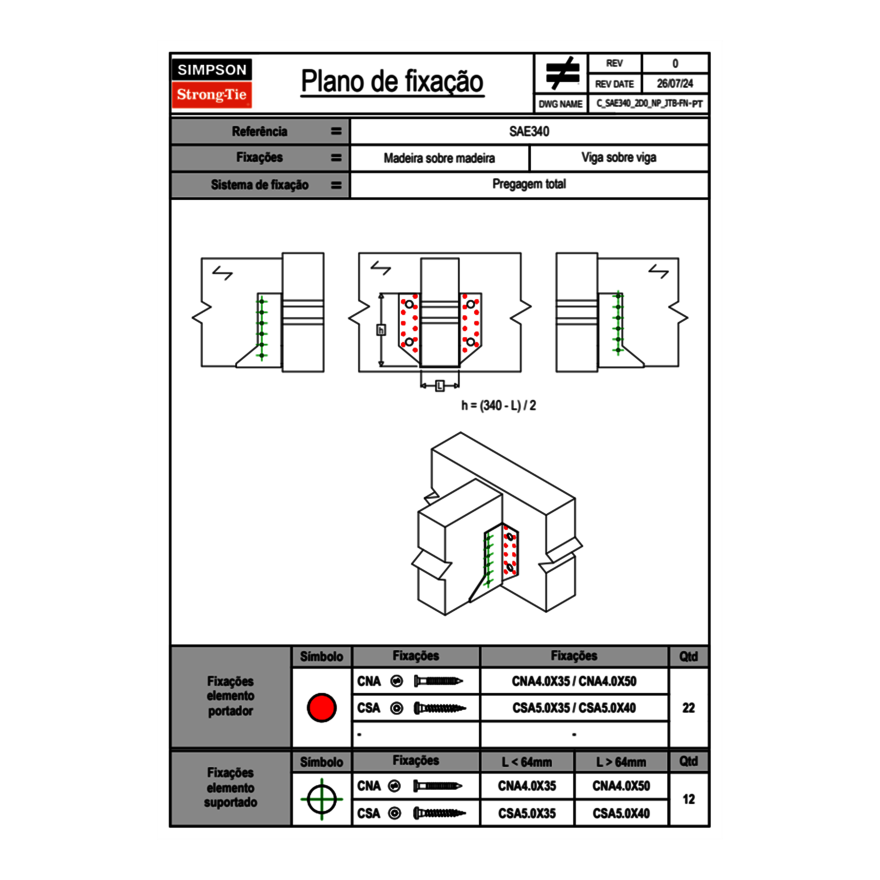

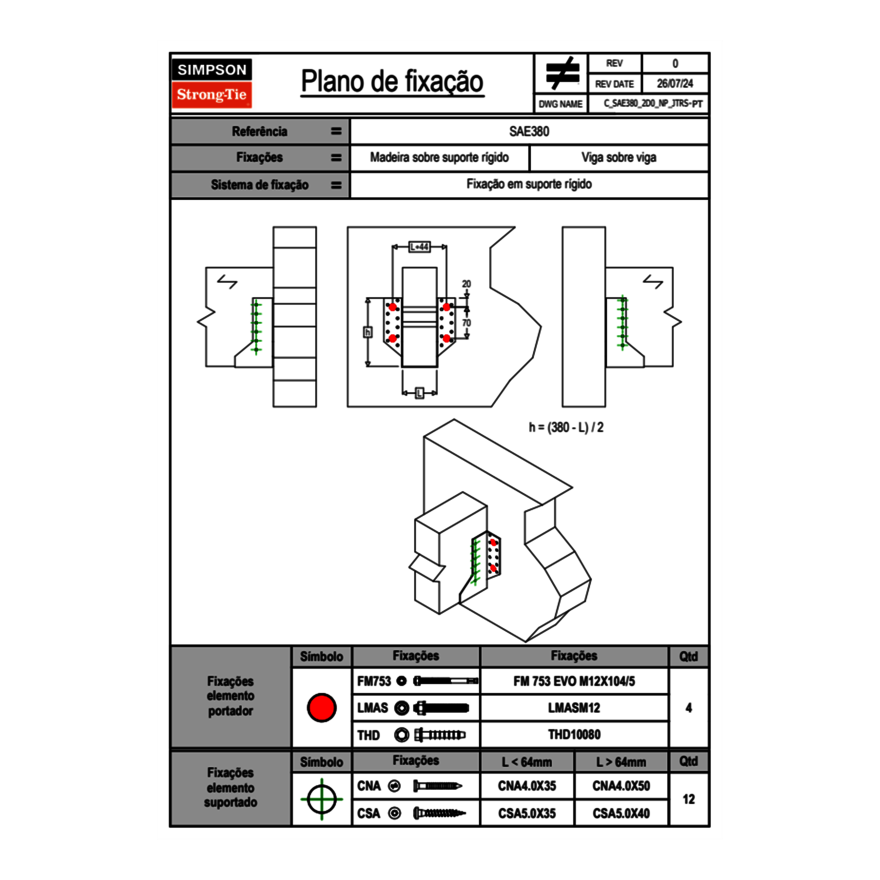

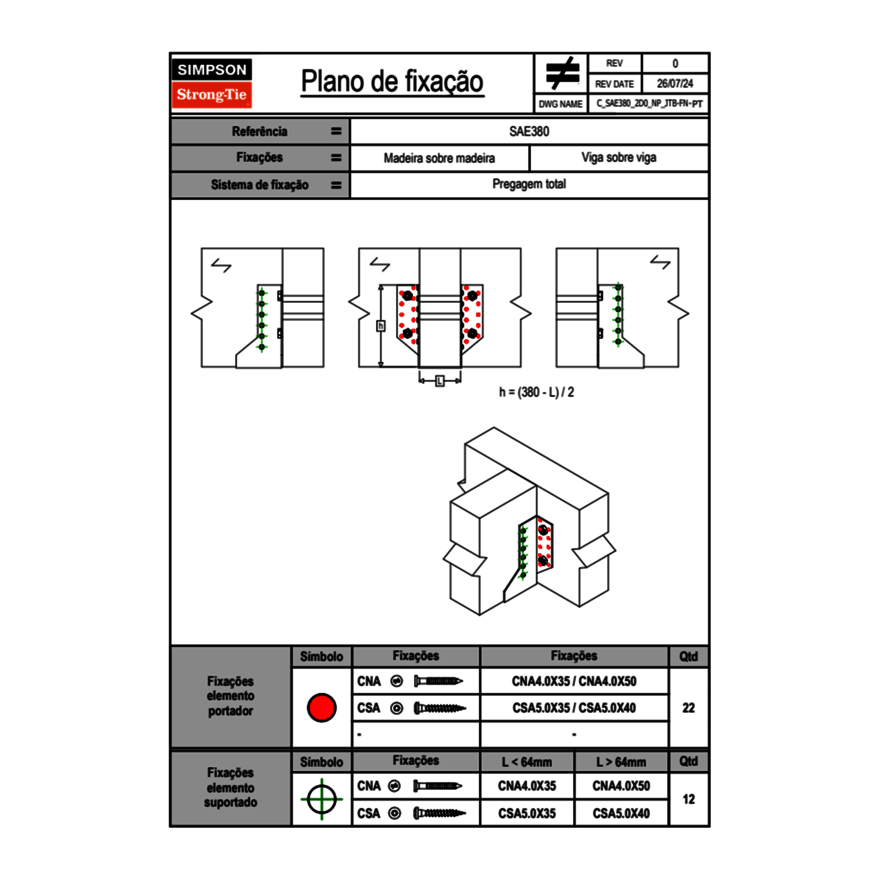

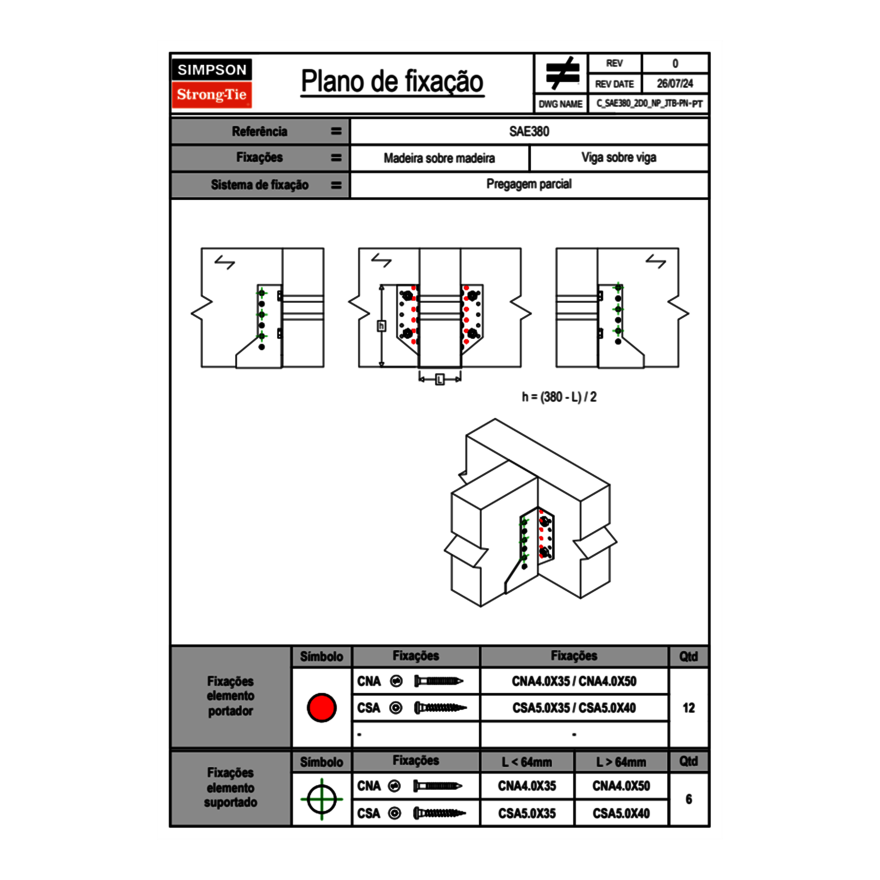

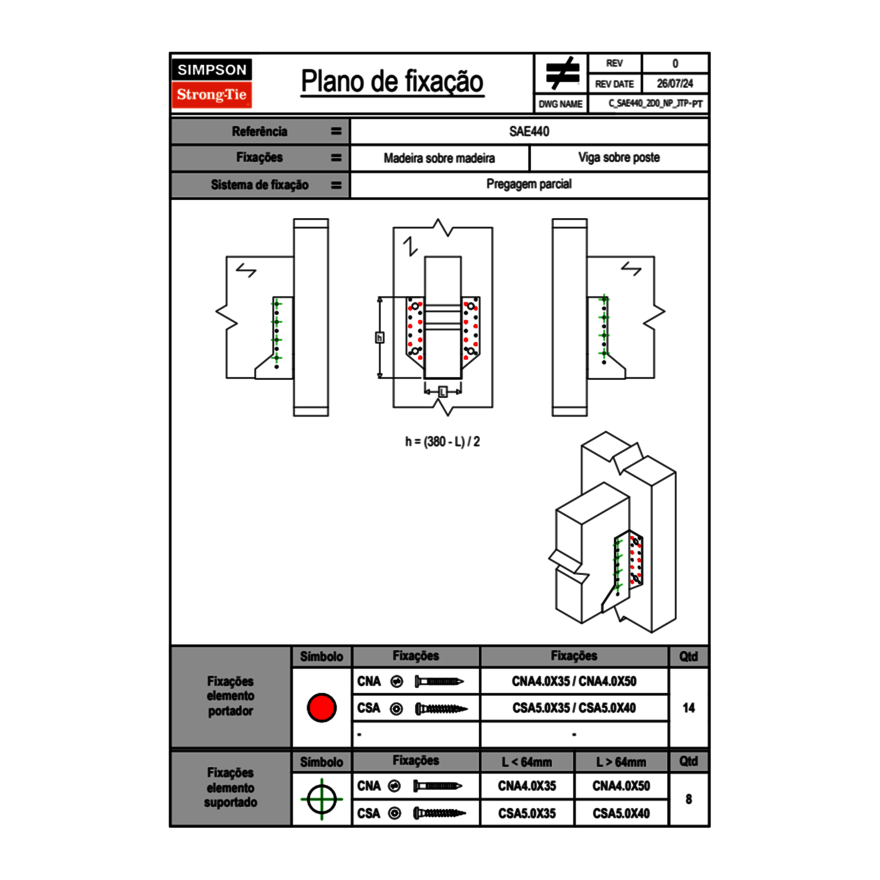

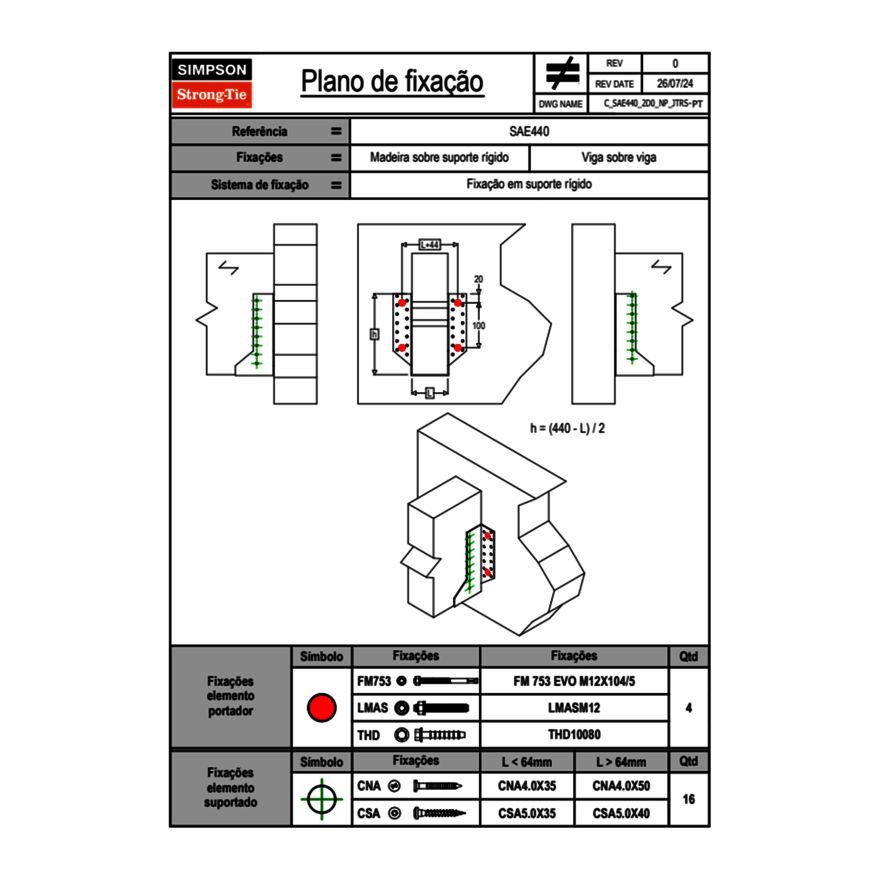

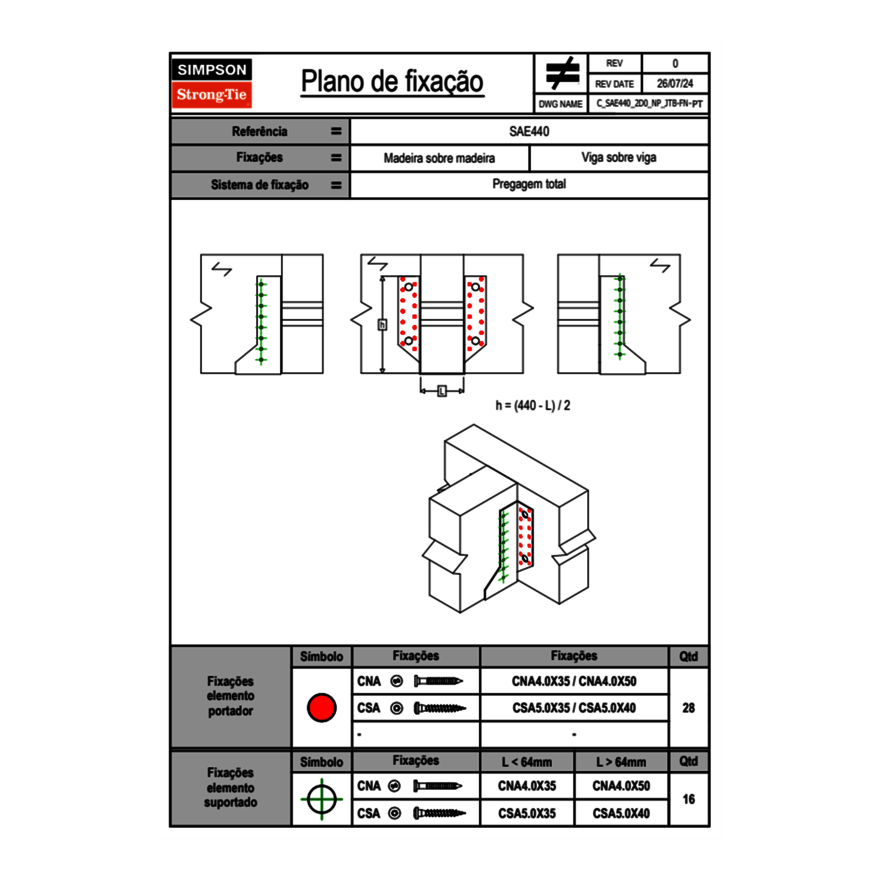

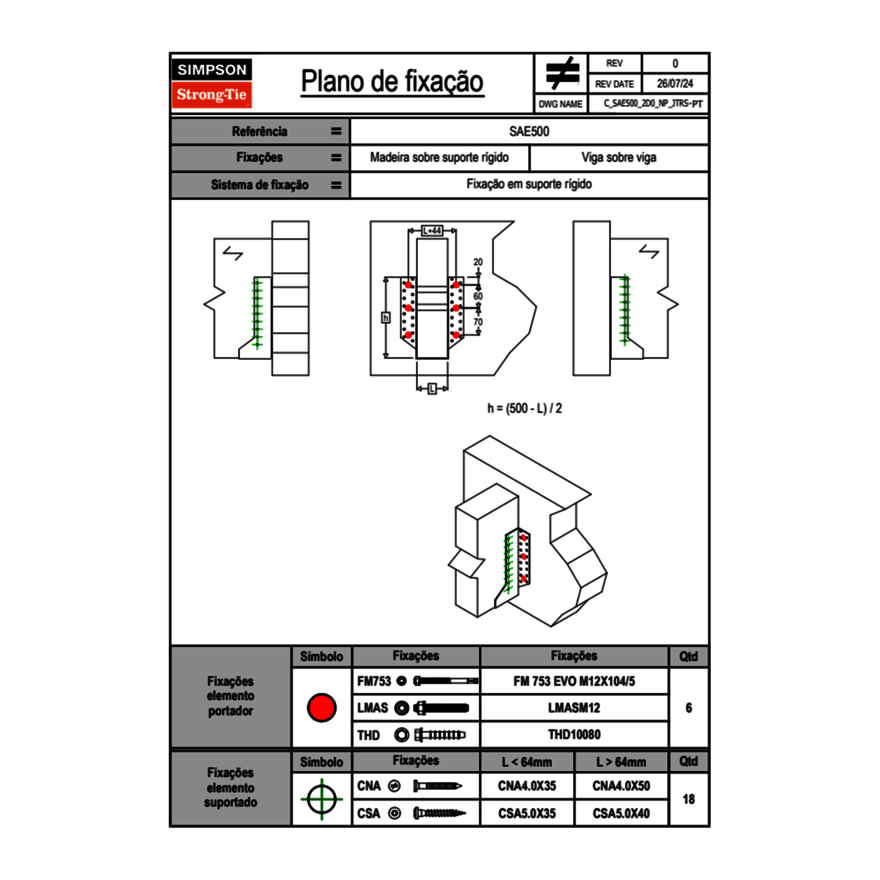

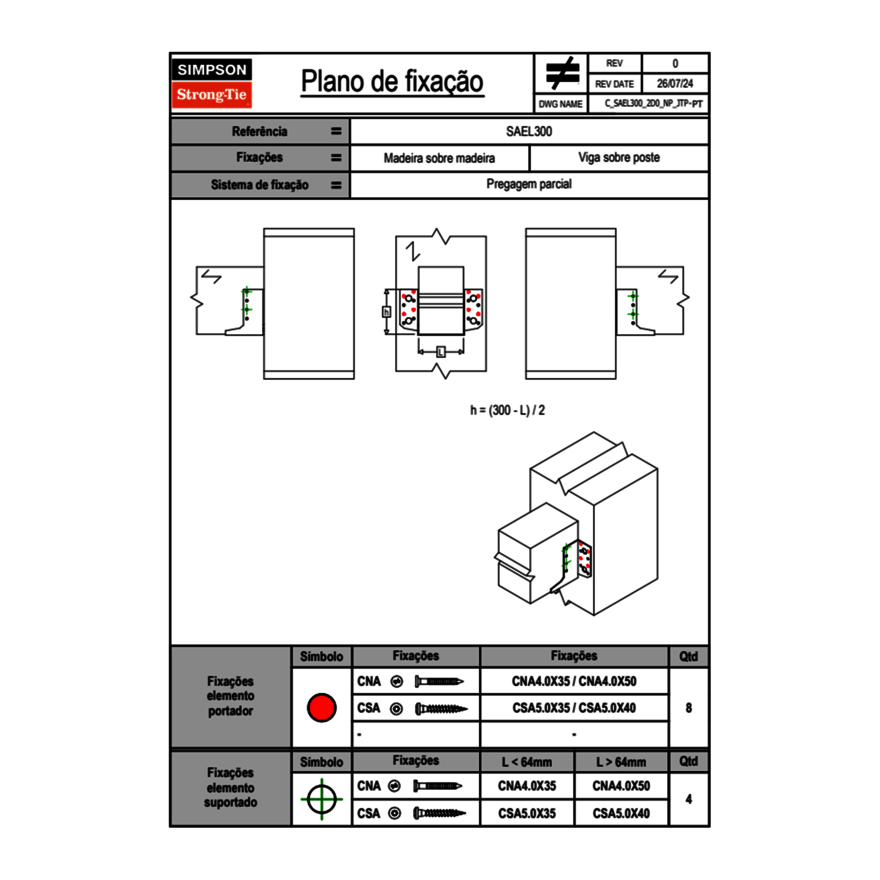

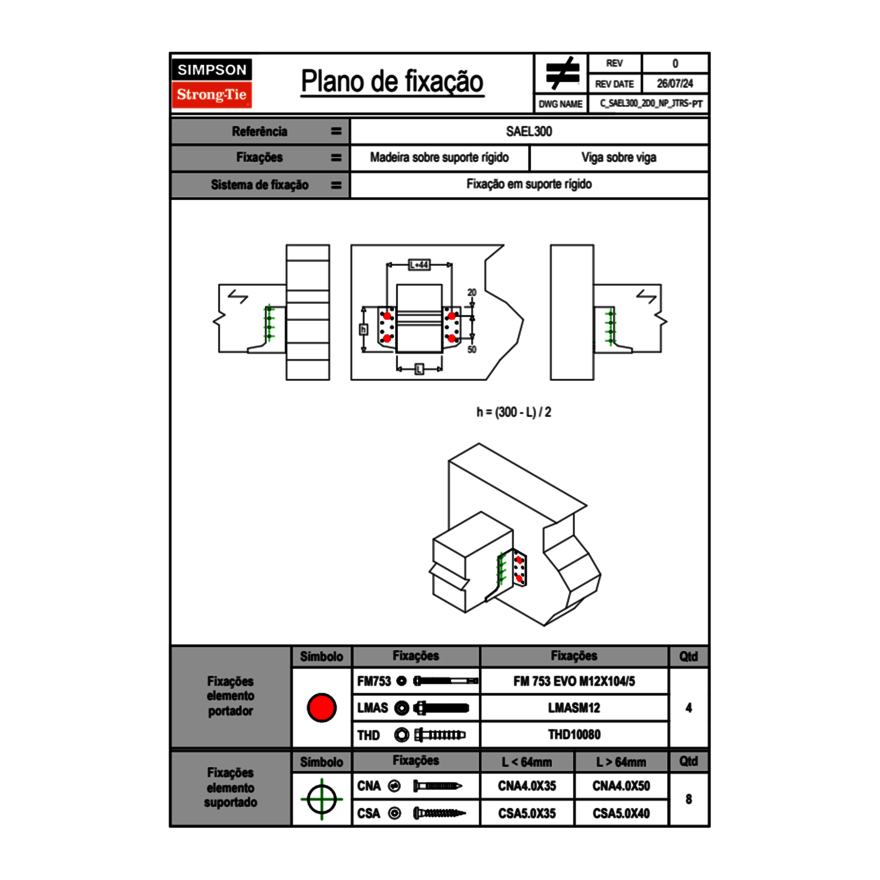

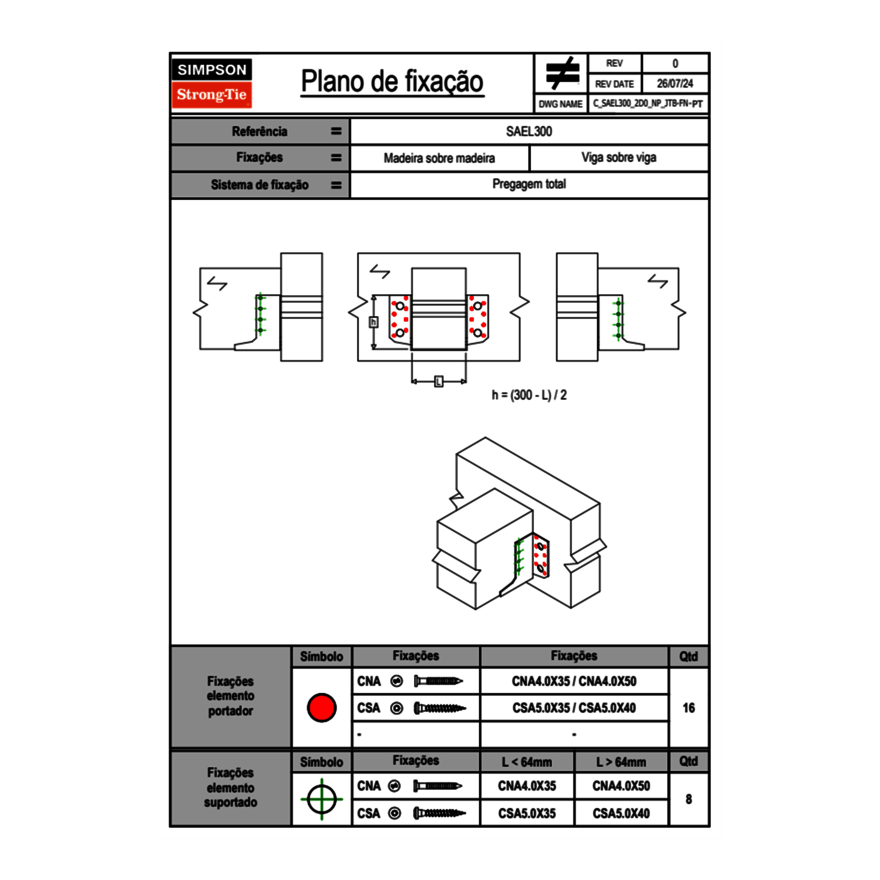

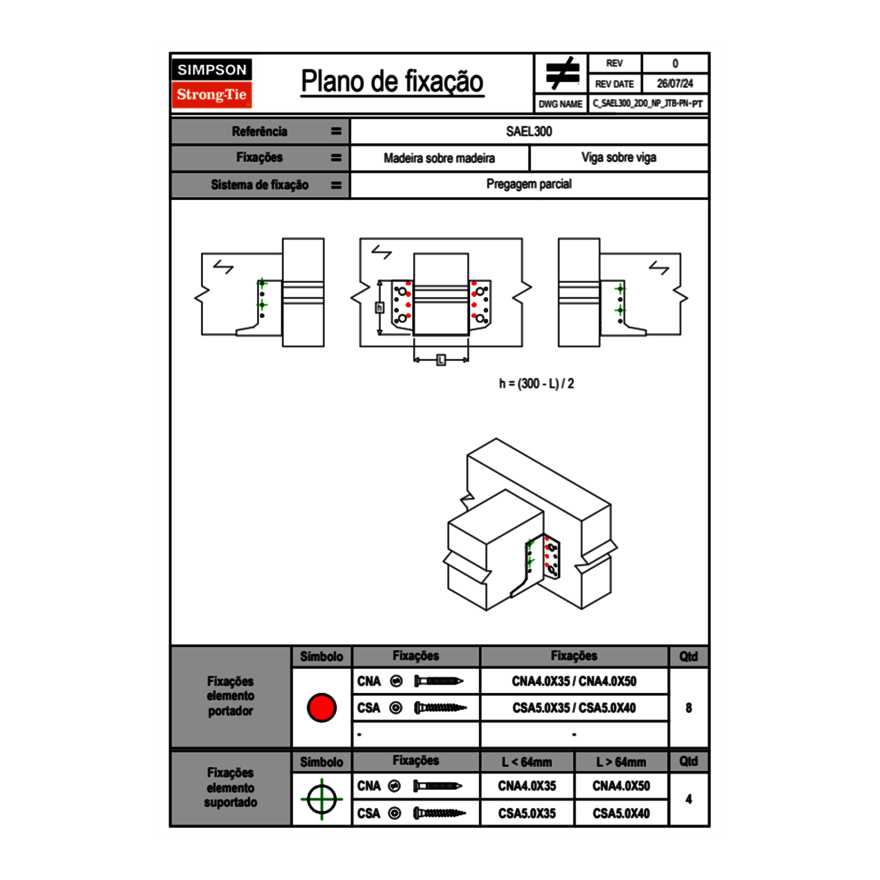

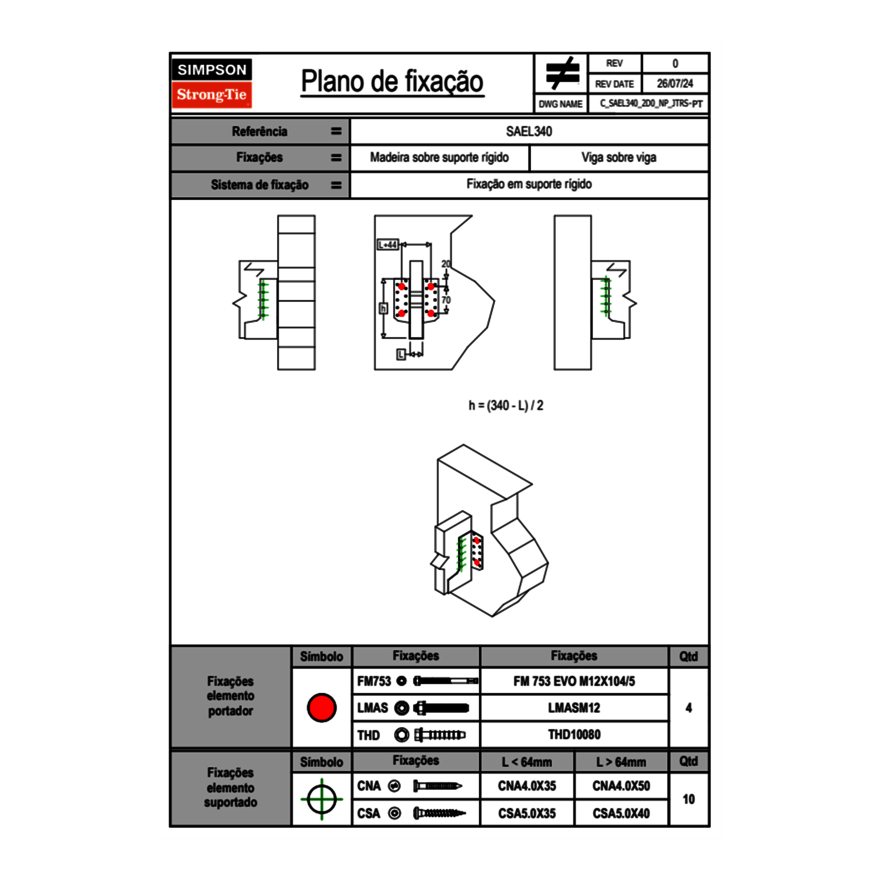

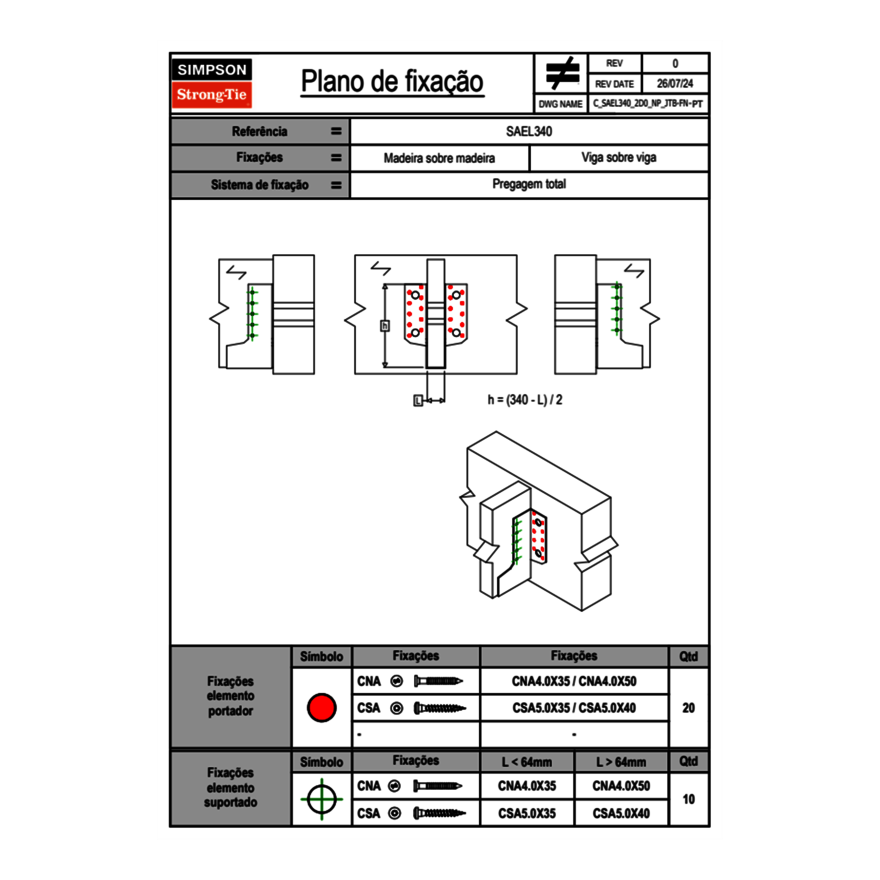

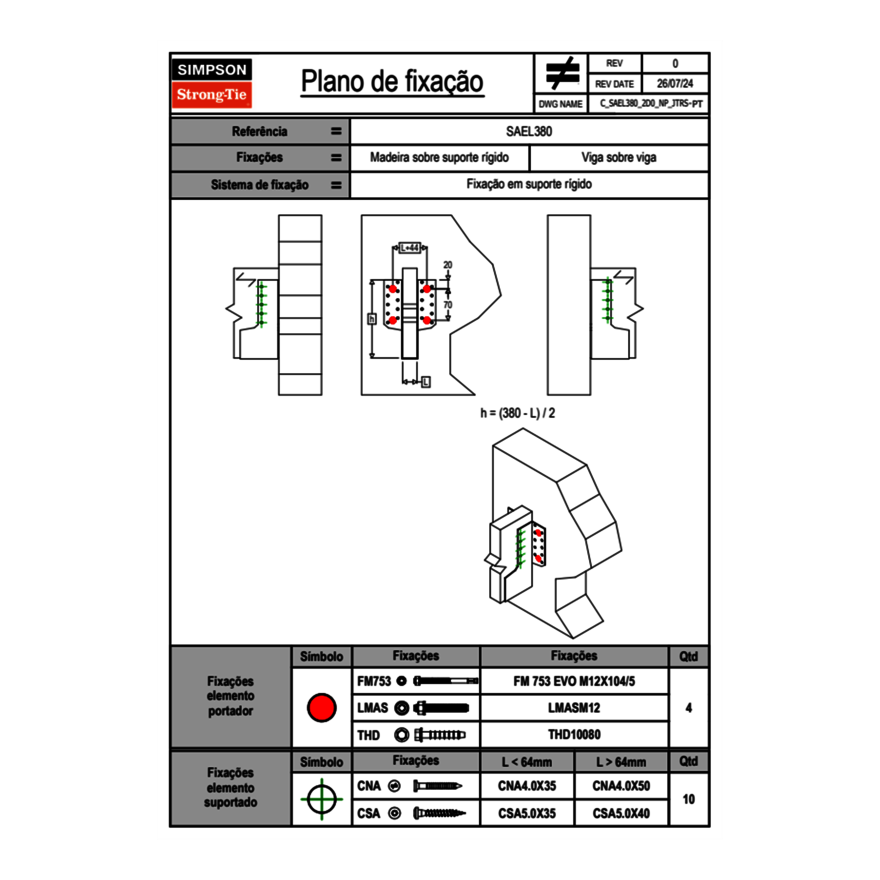

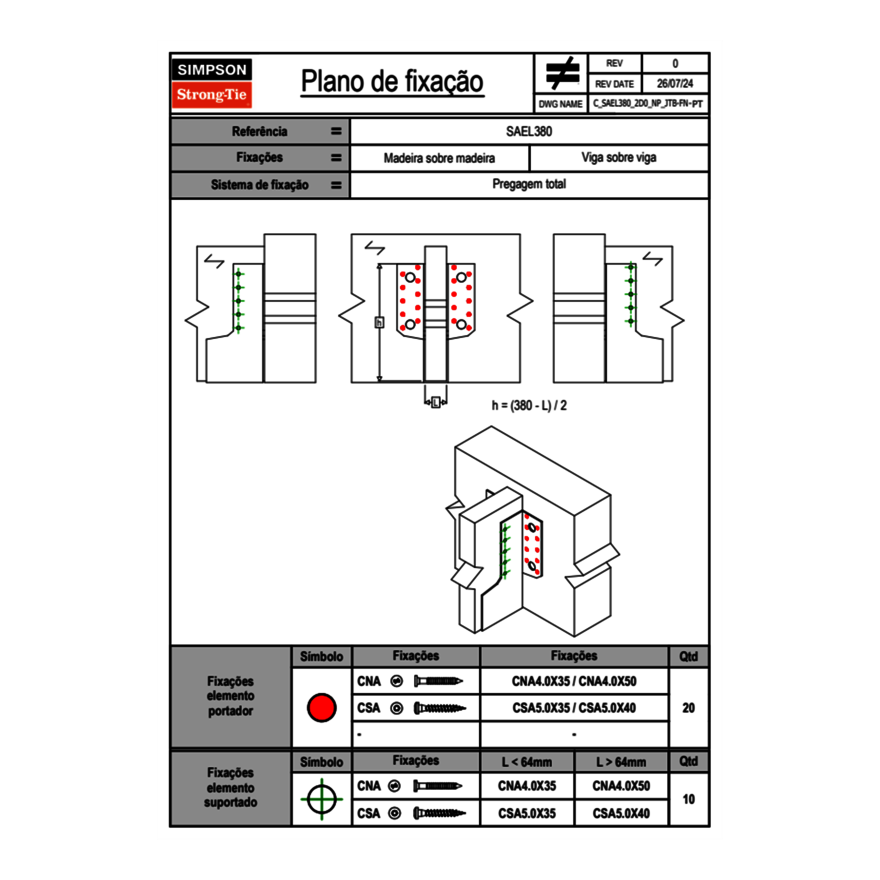

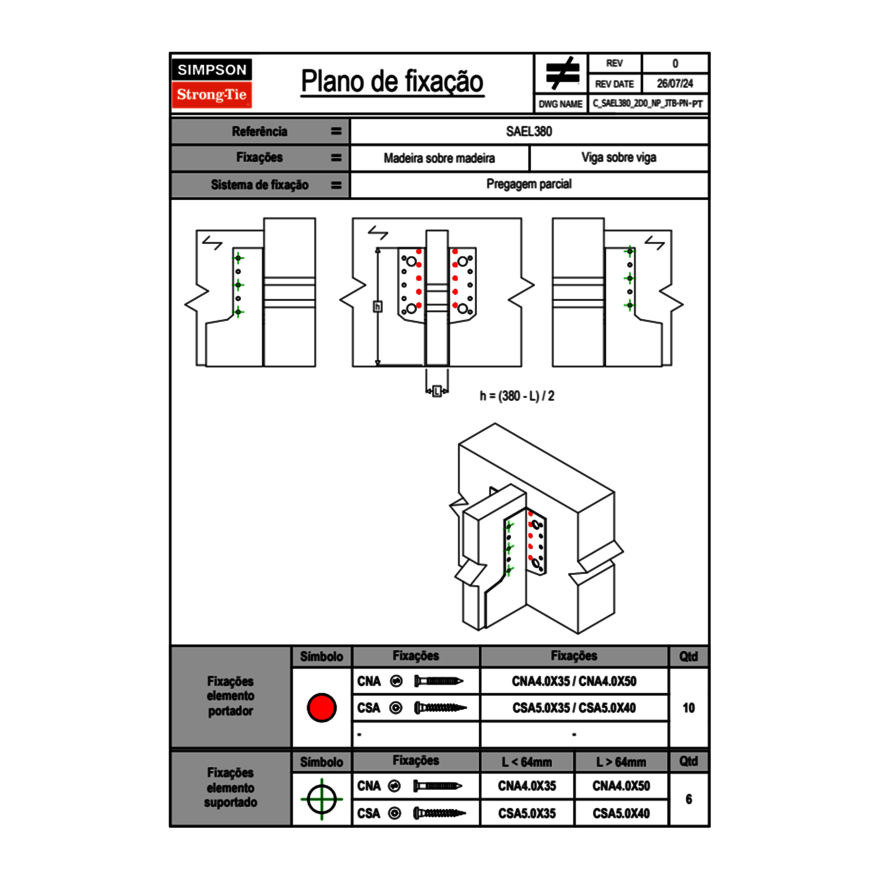

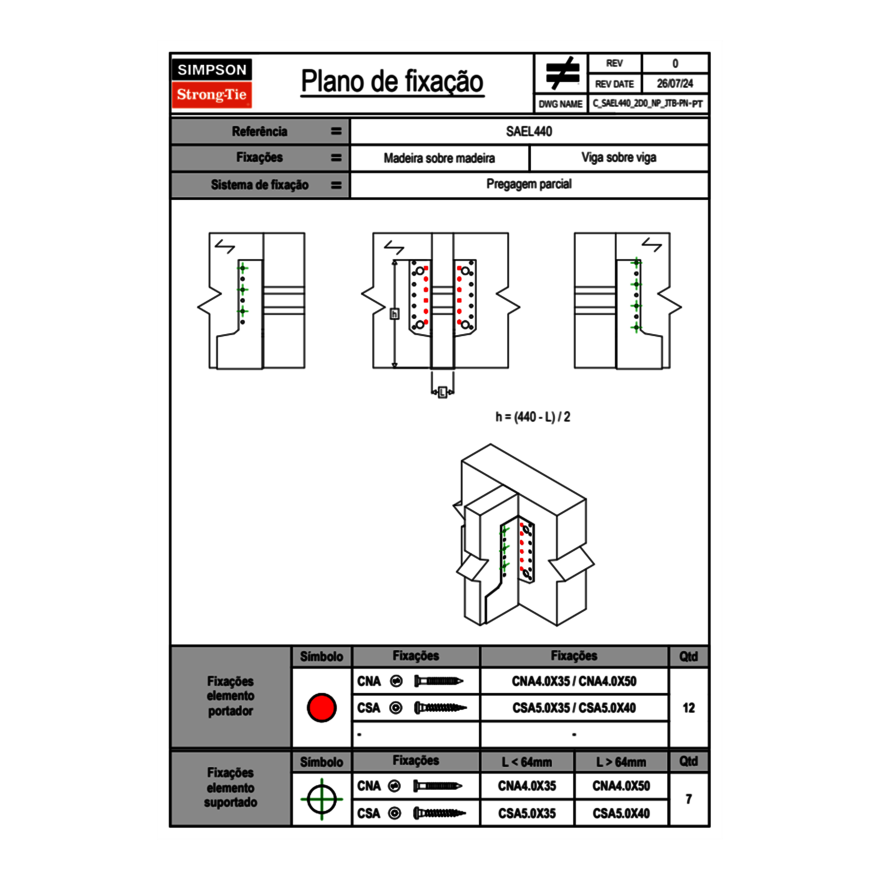

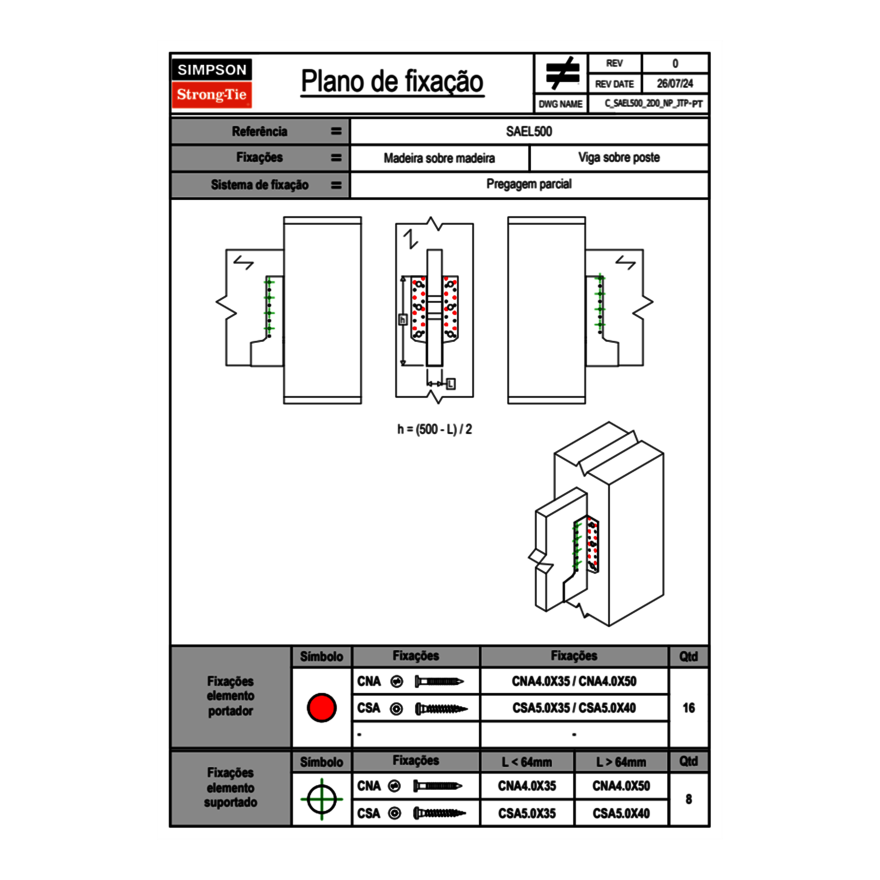

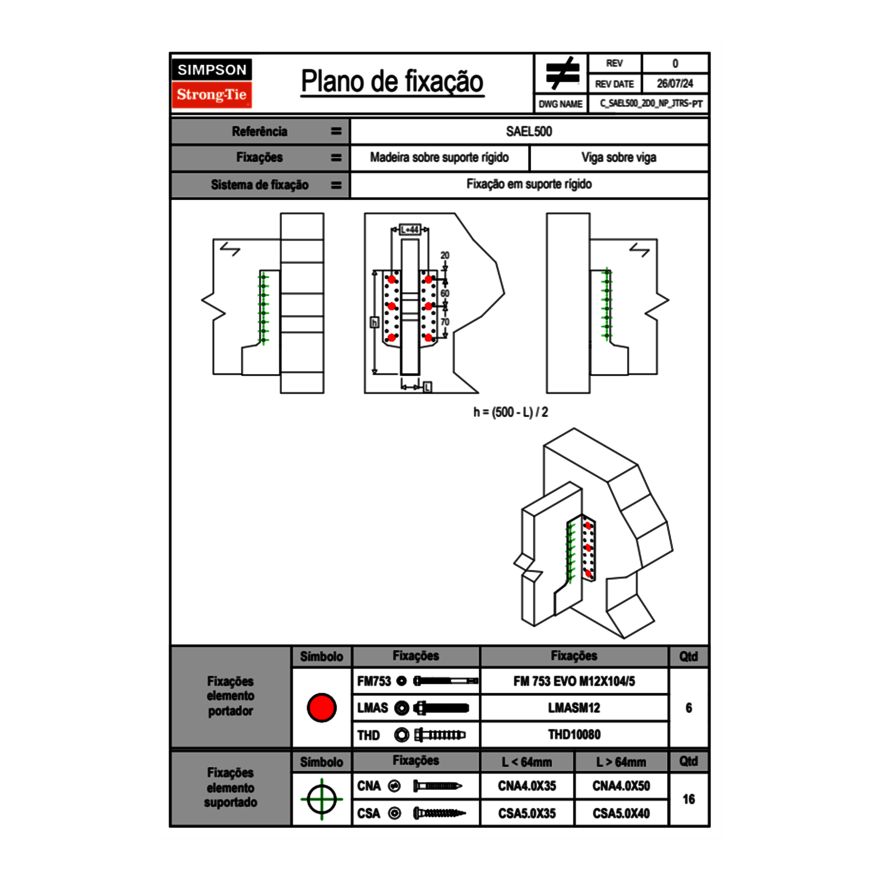

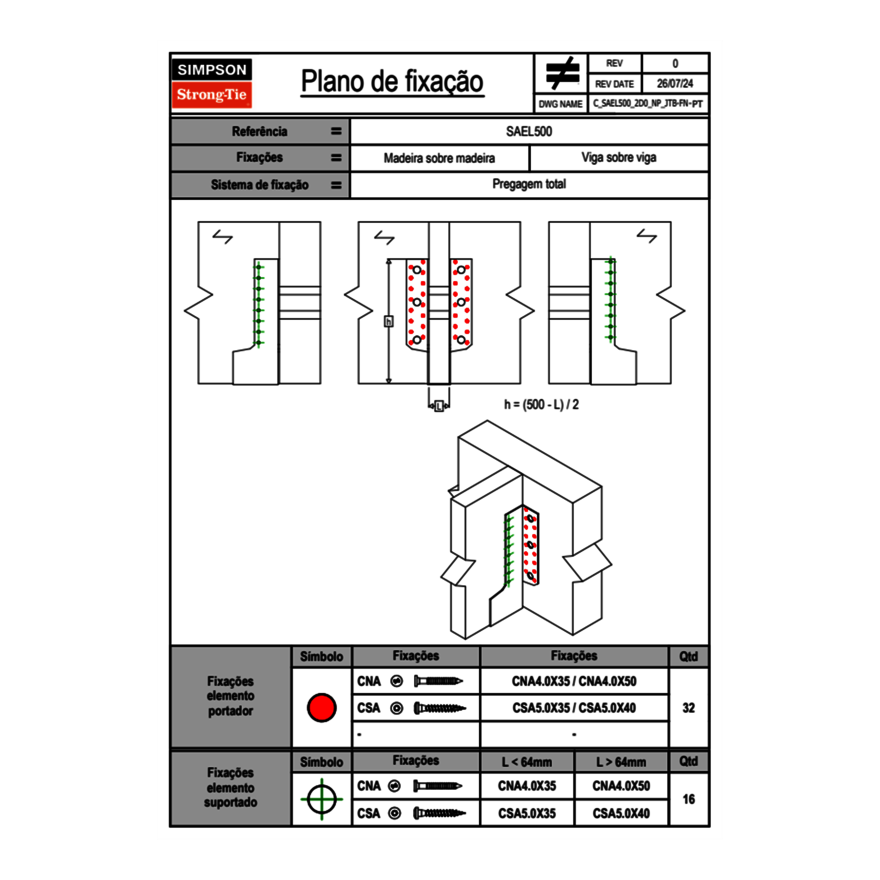

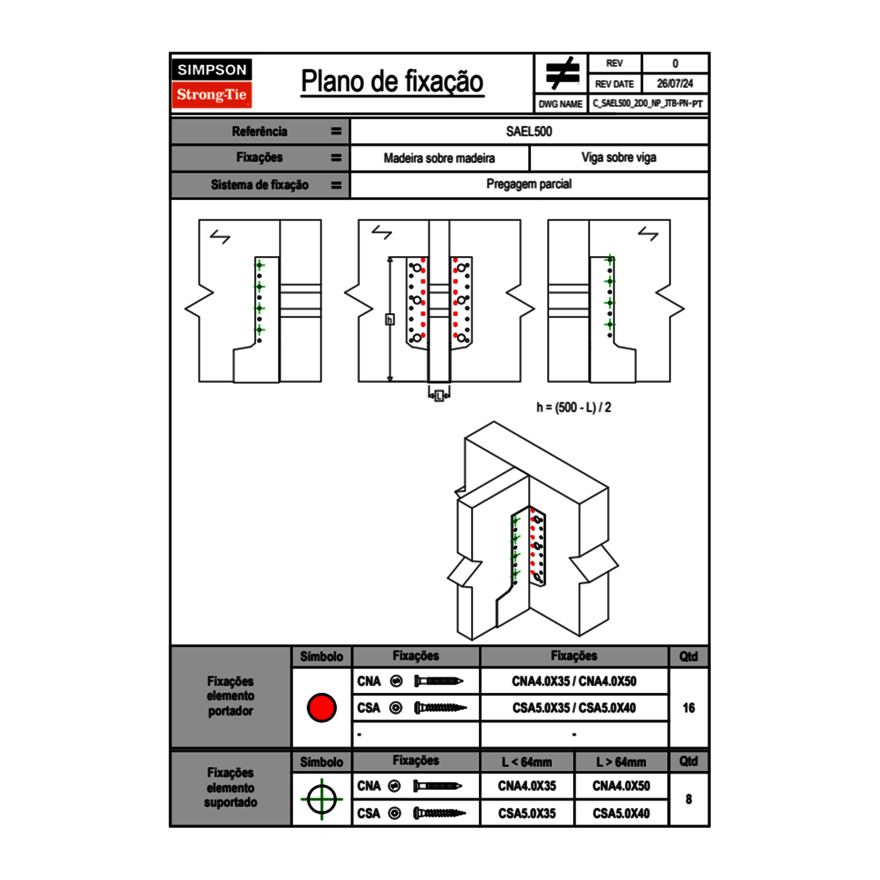

Fixações

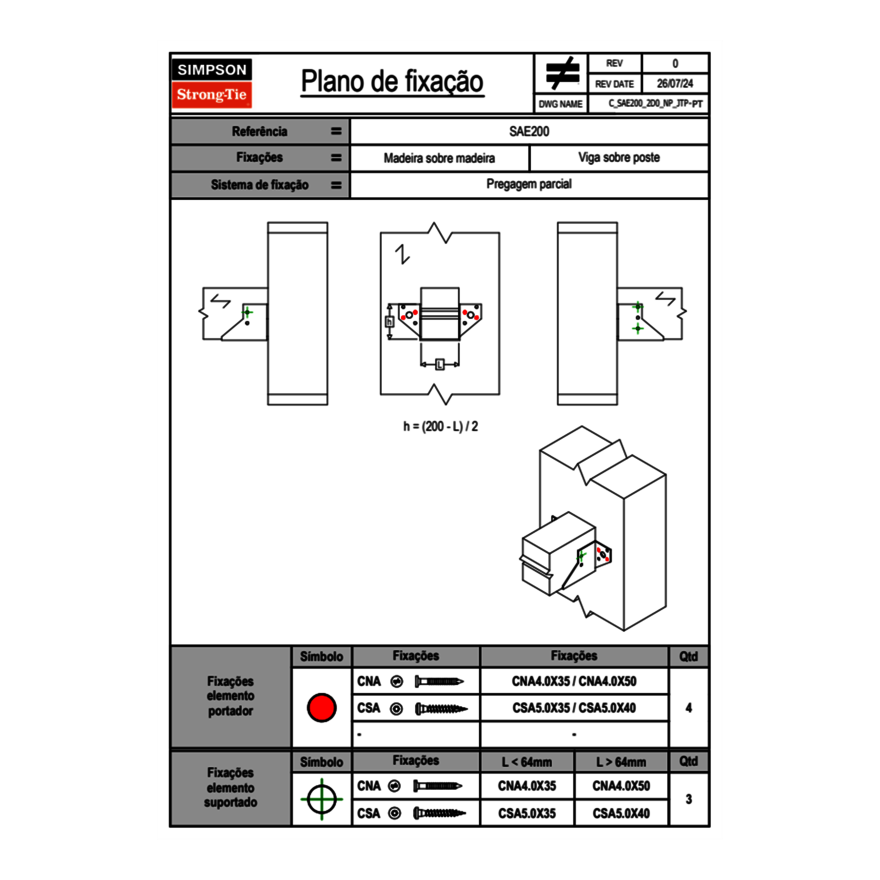

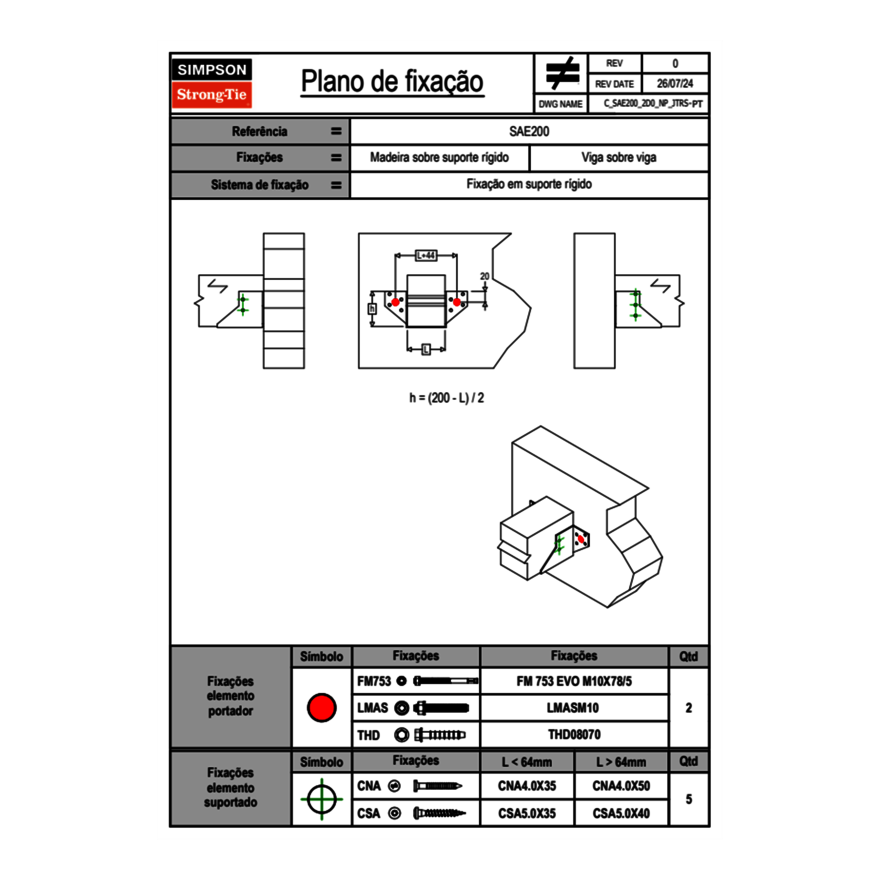

Em elemento suportado :

- Pregos canelados CNA Ø4,0 x 50 mm,

- Pregos canelados CNA Ø4,0 x 35 mm para espessuras inferiores a 64 mm,

- Parafuso CSA Ø5,0 x 40 mm,

- Parafuso CSA Ø5,0 x 35 mm para espessuras inferiores a 60 mm.

Em elemento de suporte :

Elemento de madeira :

- Pregos canelados CNA Ø4,0 x 50 mm,

- Pregos canelados CNA Ø4,0 x 35 mm para espessuras inferiores a 64 mm,

- Parafuso CSA Ø5,0 x 40 mm,

- Parafuso CSA Ø5,0 x 35 mm para espessuras inferiores a 60 mm.

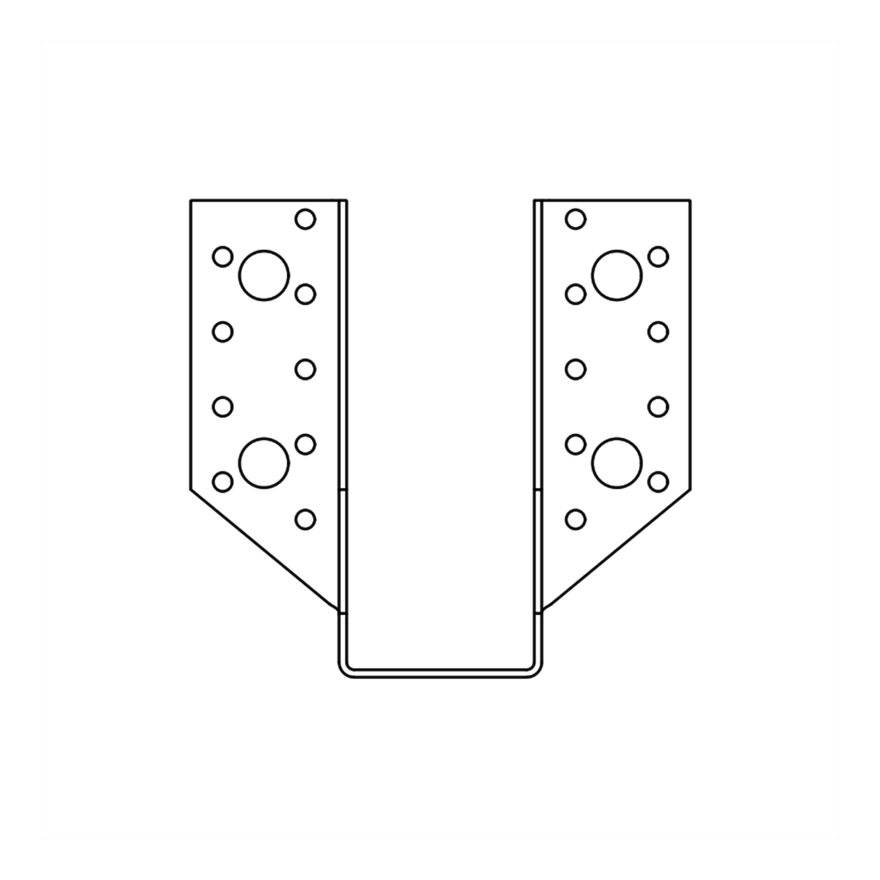

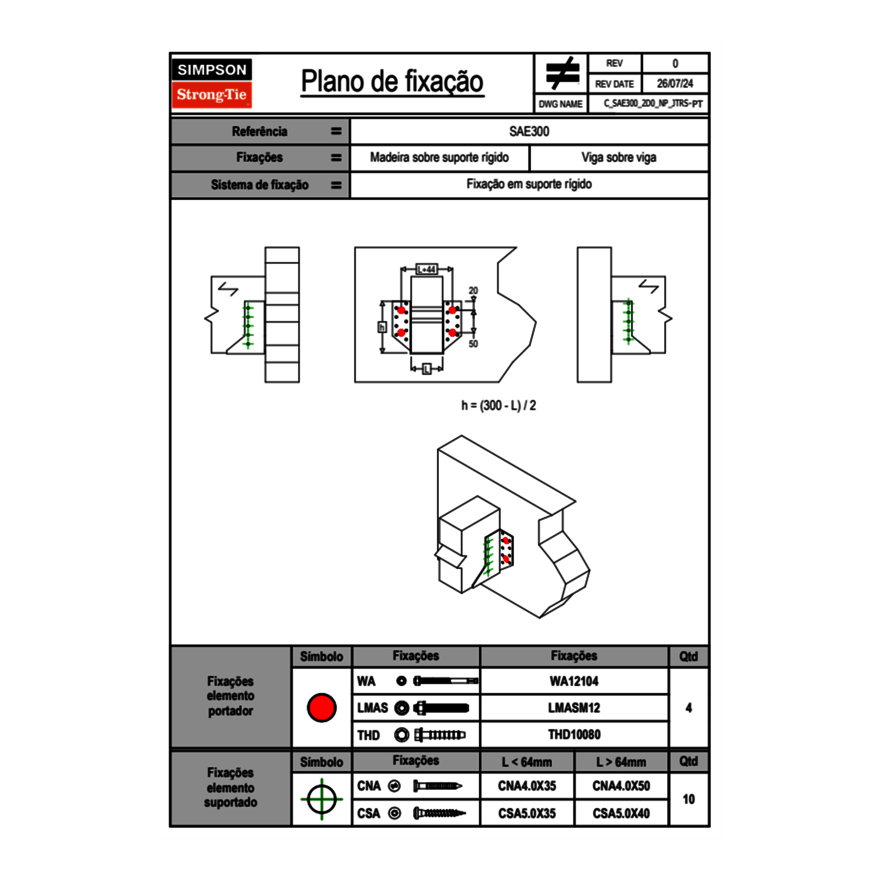

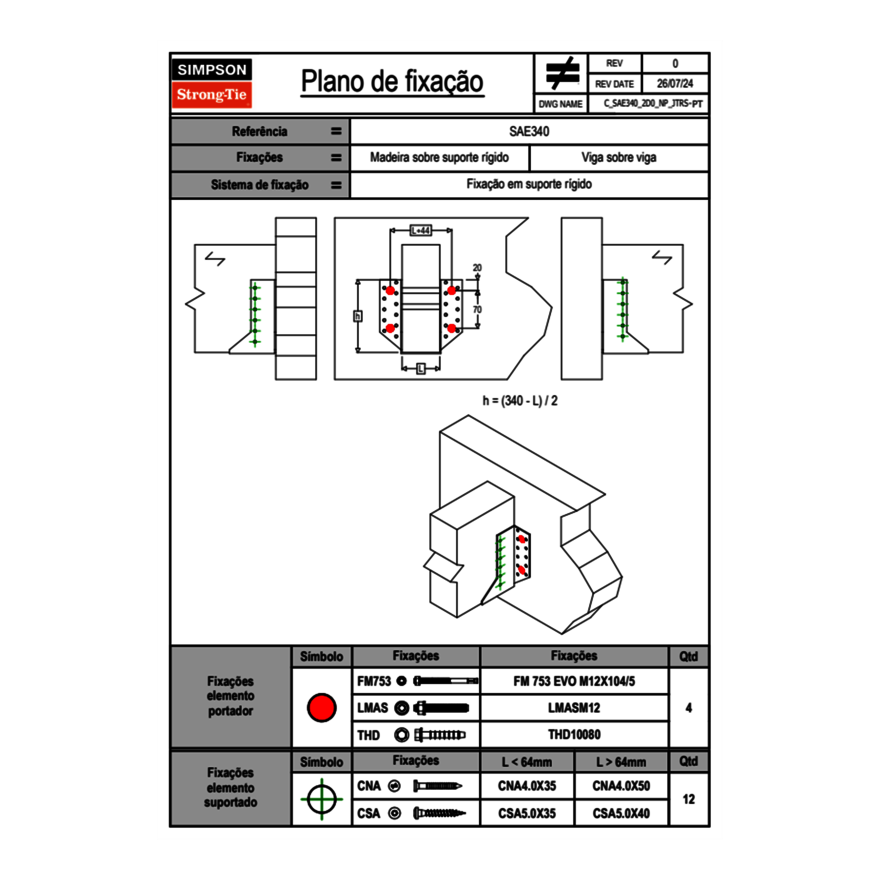

Elemento de aço :

- Parafusos Ø12 ou Ø10 mm conforme o desenvolvimento (o diâmetro do parafuso não pode ser inferior ao do furo em mais de 2 mm).

Elemento de betão :

- Cavilha mecânica : perno FM 753 EVO M10x78/5 (para os SAE200 e 250) e tipo FM 753 EVO M12x104/5 (para os SAE300, 340, 380, 440 e 500),

- Ancoragem química : resina AT-HP com haste roscada LMAS M10-120/25 (para os SAE200 e 250) e LMAS M12-150/35 (para os SAE300, 340, 380, 440 e 500).

Elemento de alvenaria de blocos ocos (verificar as capacidades de cargas das ancoragens) :

- Ancoragem química Ø 10 resina AT-HP ou POLY-GP + haste roscada LMAS M10-120/25 + peneira SH M16-130 (para os SAE200 e 250),

- Resina AT-HP ou POLY-GP + haste roscada LMAS M12-150/35 + peneira SH M20-85 (para os SAE300, 340, 380, 440 e 500).

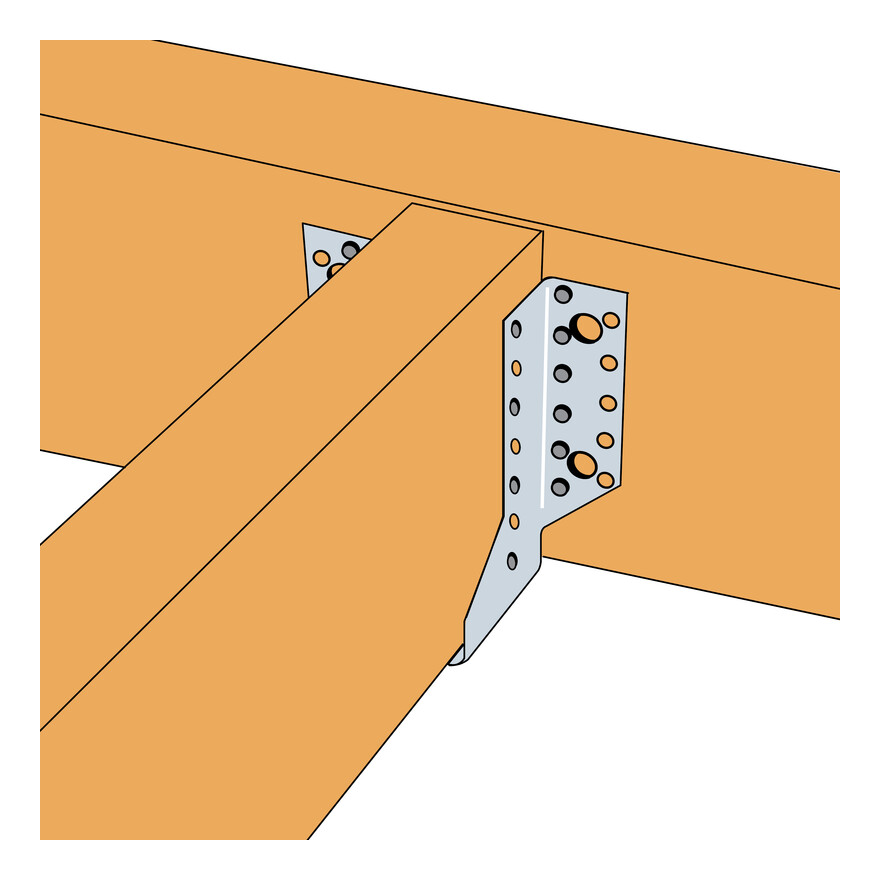

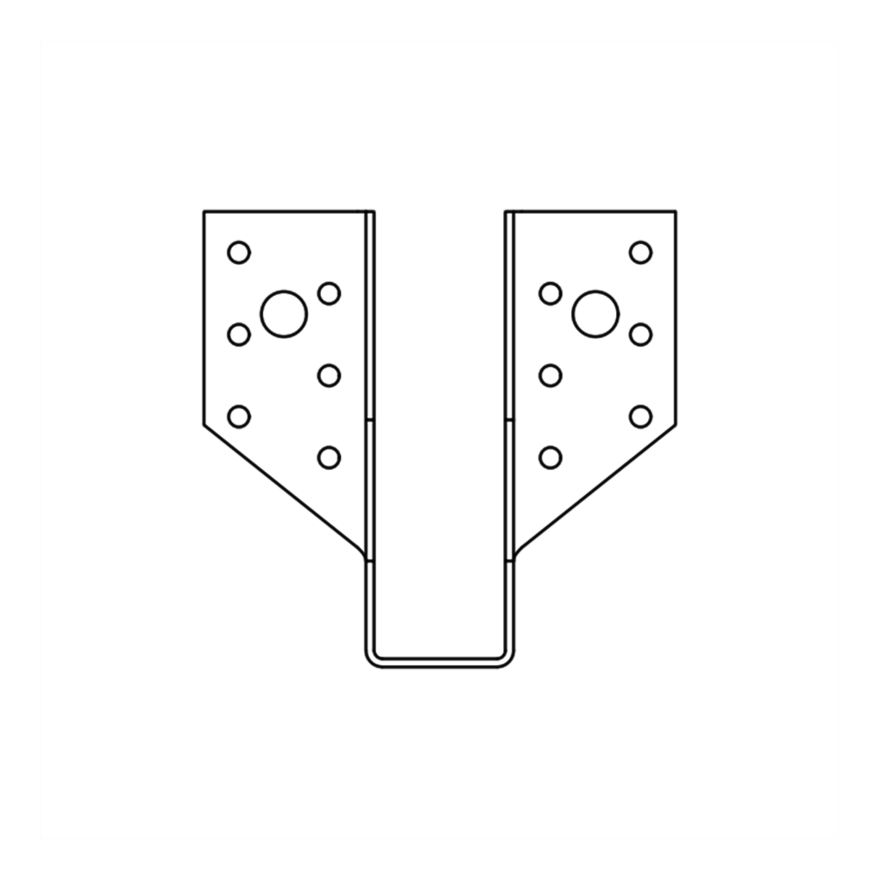

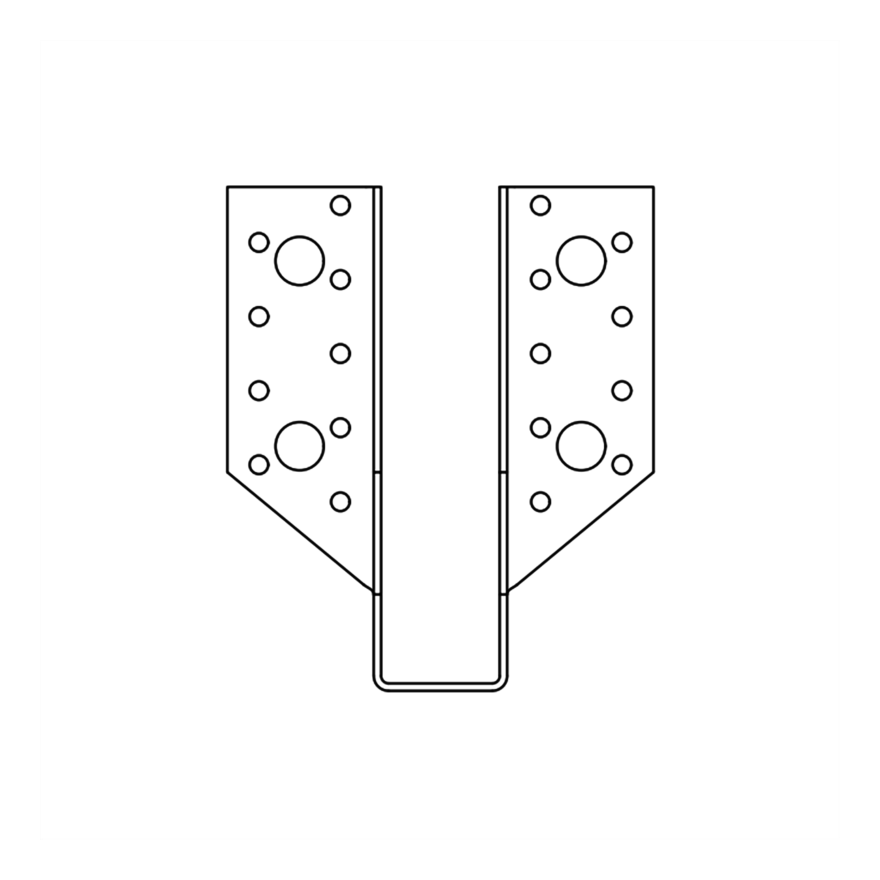

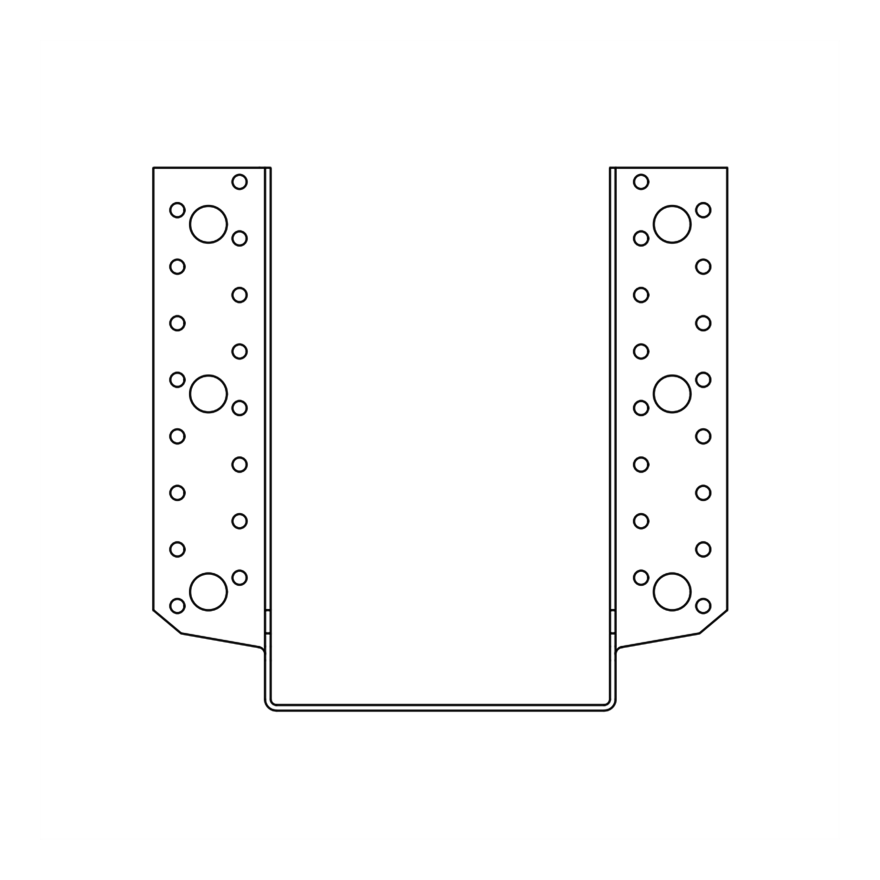

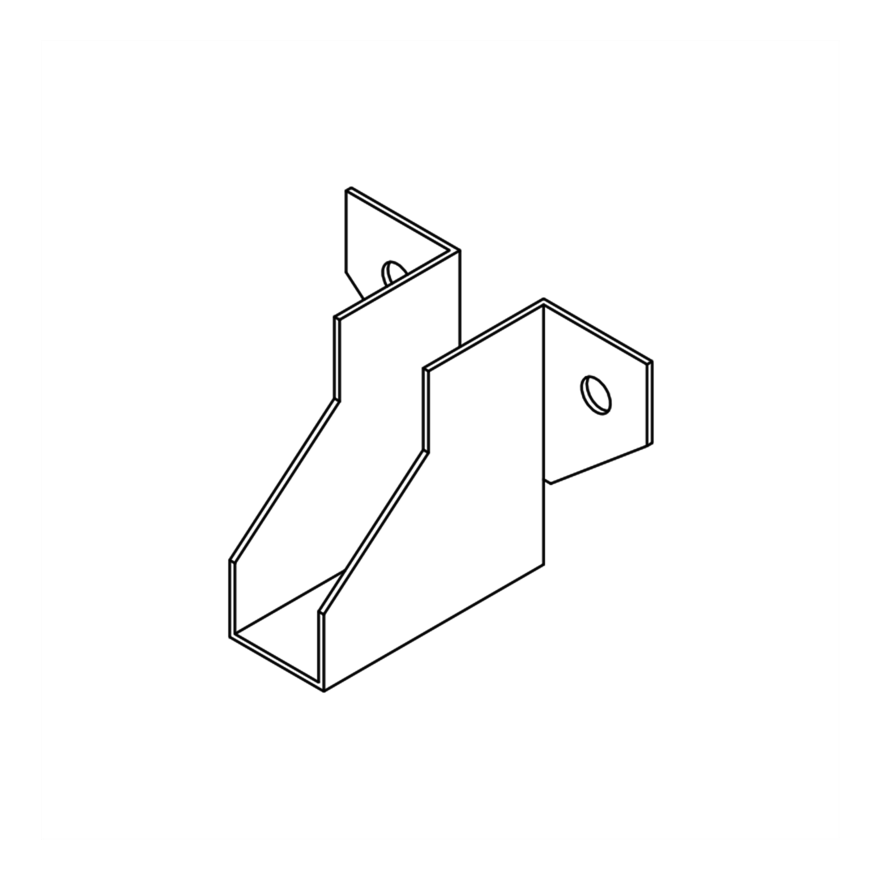

Instalação

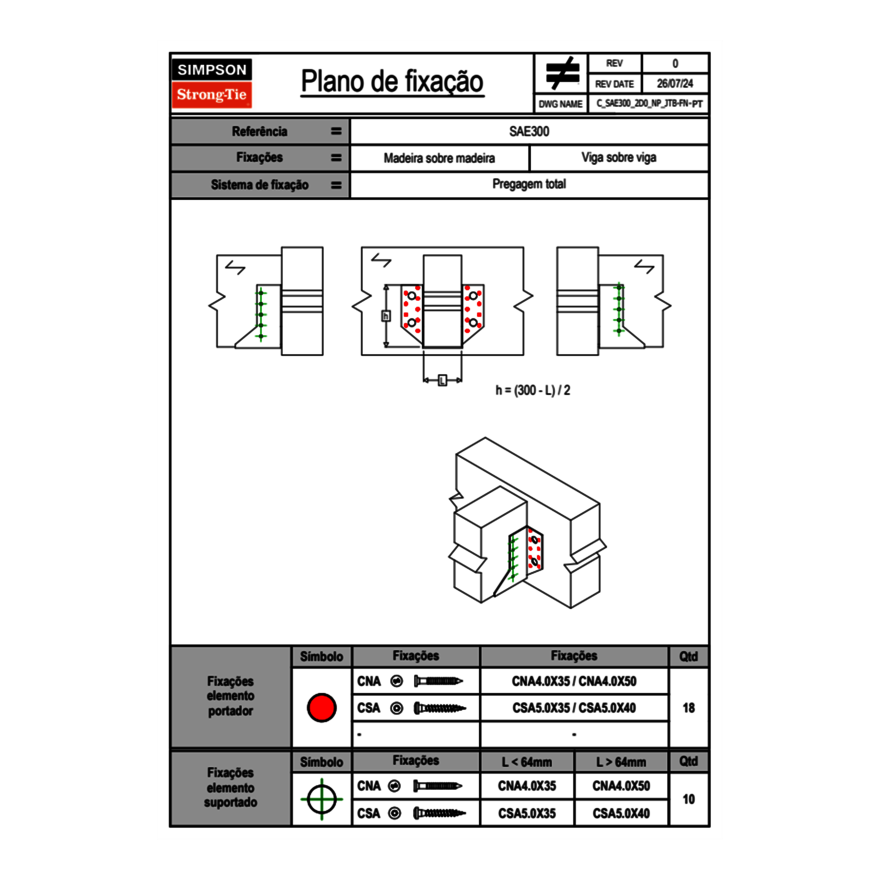

Em madeira :

- Traçar a localização da viga suportada sobre a viga.

- Posicionar o suporte e pré-fixar as abas de cada lado.

- Ajustar o suporte relativamente aos traçados. O suporte deve estar ligeiramente mais aberto em cima do que em baixo para facilitar a instalação da viga suportada.

- Finalizar a fixação de cada aba.

- Posicionar a viga no suporte.

- Posicionar a viga suportada no suporte.

- Em madeira, há dois tipos de pregagem total ou parcial.

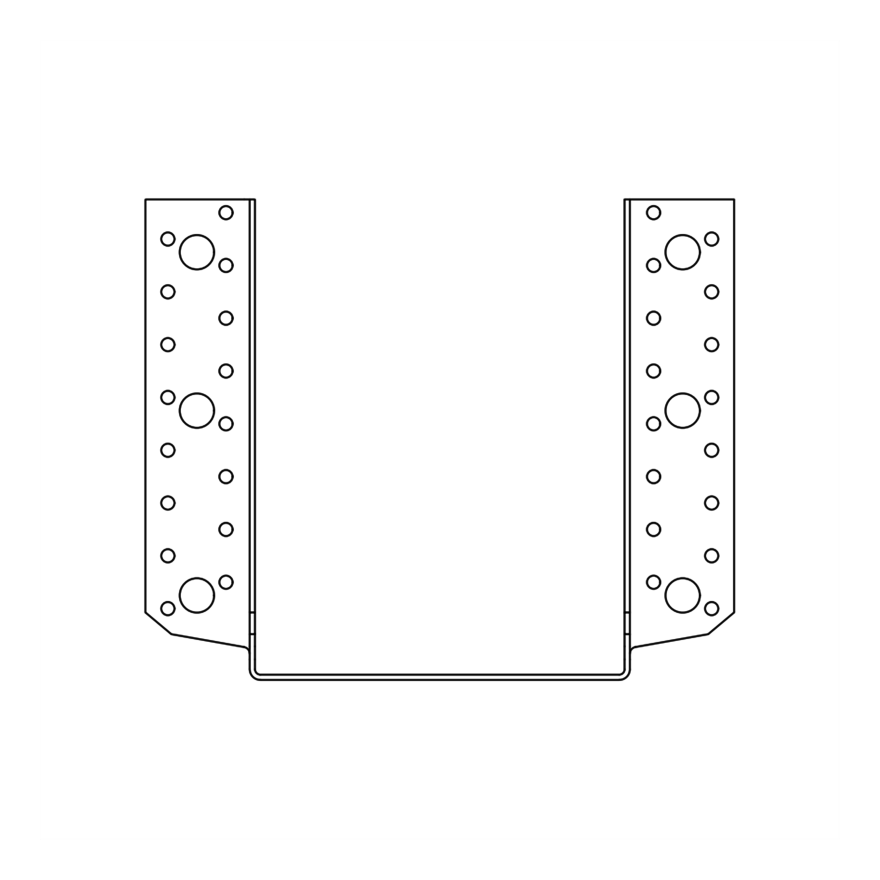

Em betão :

- Método 1 : Traçar a localização dos furos com a ajuda do quadro de posições dos furos, disponível na ficha técnica.

- Método 2 : Traçar a localização da viga sobre o elemento, posicionar o suporte e identificar o centro dos furos.

- Perfurar o elemento com uma broca adaptada.

- Posicionar o suporte e fixar o elemento com pernos de ancoragem.

- Posicionar a viga suportada no suporte.

- Fixar a viga sobre o suporte.